Fasteners for Concrete Masonry

INTRODUCTION

Buildings use a variety of connectors including anchors, wall ties and fasteners. The distinction between the these types of connectors can be confusing. The broad term “connector” is defined as “a mechanical device for securing two or more pieces, parts, or members together, including anchors, wall ties, and fasteners” (refs. 1, 2). While the terms are often used interchangeably even in technical literature and codes, anchors, wall ties and fasteners each have different purposes. Typical industry usage is:

- anchors secure masonry to its support. Examples are an anchor bolt or a column flange strap anchor used to connect a masonry wythe to a steel column.

- Ties, such as adjustable wire ties, are used to connect wythes of masonry in a multiwythe wall.

- Fasteners connect nonmasonry materials or objects to masonry. An example is a toggle bolt used to install a shelf.

This TEK discusses the use of fasteners in concrete masonry assemblies. TEK 12-01B, Anchors and Ties for Masonry (ref. 3) presents information on anchors and wall ties.

TYPES OF FASTENERS

Many fastener types are available. Fasteners for masonry are typically designed to be inset into a mortar joint, penetrate the face shell of a unit into its hollow core, or bore into a solid unit or solidly grouted wall.

Mortared-In Fasteners

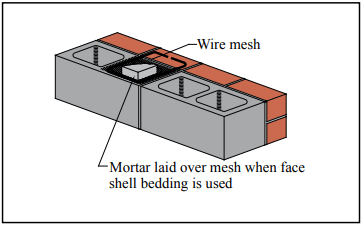

Mortared-in refers to bolts not used for structural purposes, threaded rods and other fasteners that are placed in the masonry mortar joints while the wall is being constructed. This eliminates the need to drill or nail into the masonry, but placement must be exact, as these fasteners cannot be moved or adjusted after placement. Although most fasteners are post-applied rather than mortared in, nailer blocks of pressure-treated wood or metal can be installed during wall construction.

Post-Applied Fasteners

Post-applied fasteners fall into three broad categories: hand-driven mechanical or expansion fasteners, power-actuated fastening systems and chemical/adhesive fasteners.

Hand-Driven Mechanical or Expansion Fasteners

Probably the most familiar fasteners are the hand-driven, mechanical or expansion varieties. These fasteners are offered in several types of metal and, in some cases, plastic.

There are many fastener manufacturers and a large array of mechanical and expansion fastener types (see Figure 1). Some of the most common include:

Self-tapping screws (Figure 1a) that cut threads into the concrete masonry unit or mortar joint through a predrilled hole. Most manufacturers produce these in assorted small diameters and in several lengths.

Toggle fasteners (Figure 1b) frequently called toggle bolts come in several configurations but the most common consists of a threaded bolt and a spring-loaded toggle. Once inserted through a predrilled hole into the core of a hollow concrete masonry unit, the toggle expands and bears against the masonry, holding the bolt in place.

Sleeve fasteners (Figure 1c) consist of a threaded stud with a flared cone-shaped end and an expander sleeve assembled over the stud. A washer and nut are then attached to the end of the stud. After insertion, the nut is tightened, drawing the cone-shaped end into the expander sleeve forcing it to expand and bear against the masonry.

Wedge fasteners (Figure 1d) use a nut, washer and a tapered steel stud bolt. This is surrounded by a steel clip or wedges. As the nut is tightened, the stud is drawn up into the clip or wedge, lodging them against the side of the masonry.

Drop-in fasteners (Figure 1e) typically use steel expansion shells and internal plugs which are forced into the shells, causing them to expand against the substrate.

Strike, hit or split-drive fasteners (Figure 1f) rely on a driving or hammering force on a pin, stud or nail to cause the fastener to expand against the concrete masonry unit.

Power-Actuated Fastening Systems

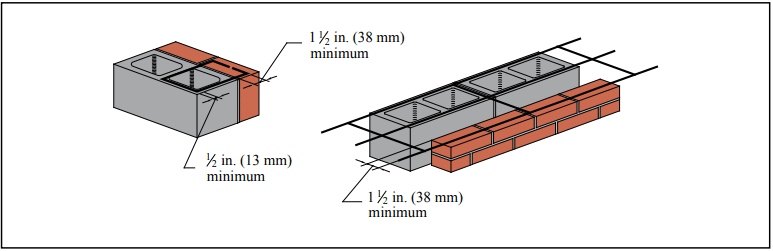

These systems use means such as explosive powder, gas combustion, compressed air or other gas or fuel to embed fasteners into concrete masonry. Of these, powder-actuated systems are most common. Powder-actuated systems use explosive powder to embed the fastener using pressure similar to that of a bullet being fired. The charges used can be more powerful than those in hand guns, so training in the proper use of the tools is critical and in many jurisdictions certification is required. These fastener systems must be fully embedded in masonry (i.e., they cannot extend into hollow areas), so manufacturers recommend that when not used in solid or solid grouted masonry, the concrete masonry face shell thickness be at least 1 ¼ in. (32 mm) thick to accommodate the length of the fastener and withstand the force of the fastener insertion.

When a powder-actuated fastener is driven into concrete masonry, the material around the fastener shank is displaced. This causes the displaced material to compress against the fastener, creating a friction hold. The heat generated during the firing process also causes a sintering, or welding, of the concrete masonry to the fastener (see Figure 2).

There are several types of powder-actuated tools: some shoot the fastener down a barrel while others use pistons to drive the fastener into the wall. The tools are divided into classes according to the velocity of the fastener. The charges also come in a range of power levels.

The fasteners for powder-actuated tools are special heat- treated steel, resulting in a very hard yet ductile fastener, which can penetrate concrete masonry without breaking. The fastener may be threaded or smooth and has a guide to align it in the tool as it is being driven. Fasteners may be packaged in multi-cartridge magazines for rapid repetitive fastening.

Chemical/Adhesive Fasteners

These fastener systems consist of smooth or deformed steel bars or rods placed in a predrilled hole and set with chemical bonding compounds such as epoxies, polyesters, vinylesters or cementitious material (see Figure 3). Loads are transferred from the fastener through the bonding compound to the masonry. Surface-mounted adhesive fasteners are available and are typically used for light-duty conditions such as attaching mirrors and frames to a finished masonry surface. Adhesive fasteners can have some advantages over mechanical expansion fasteners, such as the potential for superior strength, especially pull-out. Adhesive systems may also be more resistant to vibration than mechanical expansion anchors, and the adhesive encapsulates the steel fastener providing additional corrosion protection. Closer edge distances may also be possible with adhesive systems.

DESIGN CONSIDERATIONS AND SELECTION CRITERIA

Because of the variety of fasteners and their applications, fastener design is not addressed in detail in building codes.

Structural Considerations

Structural considerations for fasteners are similar to those for anchors, but the loads on fasteners are typically less. Fastener tension and shear capacities should be considered when selecting a fastener.

Tension is typically transferred from the fastener to the masonry by friction (as for the screw or hit fasteners), keying effects (toggle bolts or expansion systems), bonding (adhesive and chemical systems), or a combination of these mechanisms. Shear is primarily resisted by the fastener itself. As such, shear strength depends on the fastener material and its cross section.

Failure modes for fasteners are also similar to those for anchors and depend on the type of fastener, type of concrete masonry unit, concrete masonry unit compressive strength, depth of embedment, loading conditions, edge distance and fastener load/spacing between fasteners. Typical tension failure modes are fastener breakage, concrete masonry unit cone failure, concrete masonry unit splitting, edge breakouts, pull-out and, in the case of adhesive or chemical fasteners, bond failure. Shear failures include fastener breakage and back pry-out (especially with a group of fasteners or those attached into hollow CMU through the face shell) and edge breakout.

Because fasteners are in most cases proprietary products, it is important to consult the specific manufacturer’s technical data for the fastener being used. Values for pull-out, shear capacity, edge distance and embedment length criteria are given, as well as acceptable substrates and the minimum required concrete masonry unit face shell thickness.

Other Selection Criteria

In addition to the structural requirements, some other basic considerations when selecting a fastener include:

- the size, especially weight, and configuration of the item being connected to the masonry,

- whether the fastener will be subject to significant vibration,

- whether the fastener will be installed in solid or hollow concrete masonry at the attachment point,

- the minimum edge distance to keep the concrete masonry unit from splitting or spalling,

- the fastener exposure conditions,

- whether there is a need for repetitive fastener installation, in which case power-actuated systems offer an advantage,

- installer qualifications to place adhesive systems or to use powder-actuated fastener tools,

- restricted access to work areas,

- power or lighting availability,

- moisture content of masonry,

- local availability of fasteners and fastener tools, and

- other project-specific requirements or conditions.

Codes and Standards

Codes (refs. 1, 2) require that connectors be capable of resisting applied loads and that all pertinent information be included in the project documents. Manufacturer’s literature should be consulted for data pertinent to the fastener and its application. A partial list of national test methods and standards applicable to fasteners includes references 4 through 8.

Corrosion Protection

Specification for Masonry Structures (ref. 9) requires that all metal accessories be stored off the ground and protected from permanent distortions. Since most fasteners include some type of metal, corrosion protection is important. Stainless steel fasteners should conform to ASTM A480, A240 or A580 (refs. 10, 11, 12), as a minimum.

The most common form of corrosion protection for carbon steel fasteners is zinc coating or galvanizing which can be applied in several methods to achieve different coating thicknesses. Table 1 lists minimum corrosion protection requirements (ref. 9).

Galvanic Action

Because fasteners connect nonmasonry items to masonry, the potential for corrosion from galvanic action between the fastener and the item being connected to the masonry must be considered when selecting fasteners.

All metals have electrical potential relative to each other. When metals with different potentials come into contact while in the presence of moisture, the more “active” metal—the one with the more negative potential—corrodes and the other metal is galvanically protected. Table 2 presents the ranking of metals based on their electrical potential from anodic (least noble) to cathodic (most noble). The farther apart two metals are in the table, the more severe and faster the galvanic attack. The relative surface areas of the connecting metals also affect the severity of the galvanic action.

To limit galvanic corrosion, use metals that are close in the galvanic series (Table 2). If this is not possible, separate the dissimilar metals with coatings, gaskets, plastic washers, etc. The fastener should also be selected so that it is the most noble, or protected, component. Drainage is also important to ensure the fastener is not subjected to a continually moist or wet condition.

INSTALLATION

Given the number of fastening options, no one installation method fits all. It is therefore important to follow the specific fastener manufacture’s installation procedures. Some general guidelines include:

- Place fasteners with proper edge distance and spacing to prevent cracking and spalling of the concrete masonry.

- Drill holes for insertion anchors the exact diameter specified and to the specified embedment depth.

- Remove dust from predrilled holes, especially for chemical or adhesive fasteners.

- For adhesive fasteners, dispense the entire cartridge of adhesive at one time with no interruption in flow.

- With power-actuated fasteners, use test fastenings to determine the lowest power level that will insert the fastener to the proper depth and position without damaging the concrete masonry.

- Hold power-actuated tools perpendicular to the masonry surface when firing to avoid ricocheting fasteners.

- Never fire powder-actuated fasteners into masonry head joints.

- Store powder loads in separate locked containers away from heat sources. Store the tool unloaded in a locked case.

- Verify any required installer certification for operation of powder-actuated tools. Sources of information on installation methods include references 17 and 18.

- Follow all recommended safety procedures.

REFERENCES

- International Building Code 2003. International Code Council, 2003.

- Building Code Requirements for Masonry Structures, ACI 530-05/ASCE 5-05/TMS 402-05. Reported by the Masonry Standards Joint Committee, 2005.

- Anchors and Ties for Masonry, TEK 12-01B. Concrete Masonry & Hardscapes Association, 2011.

- Acceptance Criteria for Fasteners Power-Driven into Concrete, Steel and Masonry Elements, ICC Engineering Services Report AC 70 – October 2004. International Code Council Engineering Services Evaluation Committee, Whittier, CA, 2004.

- Standard Test Method for Strength of Anchors in Concrete and Masonry Elements, ASTM E488-96 (2003). ASTM International, 2003.

- Standard Test Method for Pullout Resistance of Ties and Anchors Embedded in Masonry Mortar Joints, ASTM E754-80 (2000)e1. ASTM International, 2000.

- Standard Test Methods for Strength of Power-Actuated Fasteners Installed in Structural Members, ASTM E1190-95 (2000)e1. ASTM International, 2000.

- Standard Test Methods for Testing Bond Performance of Bonded Anchors, ASTM E1512-01. ASTM International, 2001.

- Specification for Masonry Structures, ACI 530.1-05/ASCE 6-05/TMS 602-05. Reported by the Masonry Standards Joint Committee, 2005.

- Standard Specification for General Requirements for Flat-Rolled Stainless and Heat- Resisting Steel Plate, Sheet, and Strip. A480/A480M-05. ASTM International, 2005.

- Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications. A240/A240M- 05a. ASTM International, 2005.

- Standard Specification for Stainless Steel Wire. A580/A580-98(2004). ASTM International, 2004.

- Standard Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy- Coated (Galvannealed) by the Hot-Dip Process, ASTM A653/A653M-05. ASTM International, 2005.

- Standard Specification for Zinc Coating (Hot-Dip) on Iron and Steel Hardware, ASTM A153/A153-05. ASTM International, 2005.

- Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products, ASTM A123/A123M-02. ASTM International, 2002.

- Standard Specification for Steel Wire, Epoxy-Coated, ASTM A899-91(2002). ASTM International, 2002.

- PATMI Basic Training Manual, Powder Actuated Tool Manufacturers’ Institute, 2005.

- Using Powder Activated (Ammunition) Tools – Study Materials for the Certificate of Fitness Exam for E-21. New York City Fire Department, 2001.