Sampling and Testing Concrete Masonry Units

INTRODUCTION

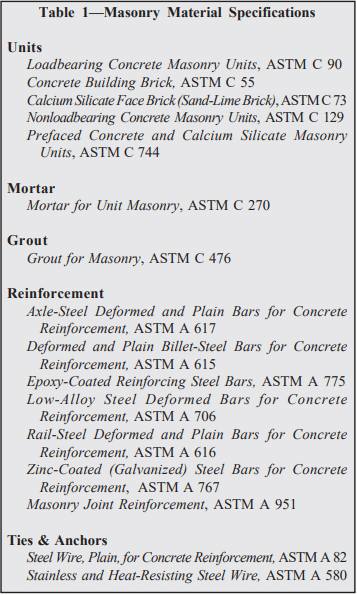

Standards for sampling and testing concrete masonry units are developed by the technical committees of ASTM International in accordance with consensus procedures. These standards reflect the expert opinion of researchers, concrete masonry manufacturers, designers, contractors and others with an interest in quality standards for concrete masonry.

The most commonly used ASTM standards for concrete masonry unit testing include: Standard Test Methods for Sampling and Testing Concrete Masonry Units and Related Units, ASTM C140 (ref. 1), and Standard Test Method for Linear Drying Shrinkage of Concrete Masonry Units, ASTM C426 (ref. 2).

SAMPLING & TESTING CONCRETE MASONRY UNITS, ASTM C140

Unit Sampling

The purpose of selecting multiple samples for unit testing is to ensure that the range of results is representative of the entire lot of units from which the specimens were taken. Consequently, concrete masonry units chosen for testing should be randomly sampled. Choosing units from one portion of a pallet, or choosing the most or least desirable units may misrepresent the properties of the lot.

Although a shipment may consist of several different unit configurations, samples for testing should all have the same configuration and dimensions. In some cases, such as shrinkage results under ASTM C426 (ref. 2), it is generally acceptable to consider the test results of one unit configuration to be representative of units with different configurations provided they were made using the same mix design, manufacturing and curing procedures.

Units that are representative of the entire lot of units are sampled from the job site or may be sampled from the manufacturer’s storage inventory. Sampled units are marked with a unique identification and weighed.

Measurement of Dimensions

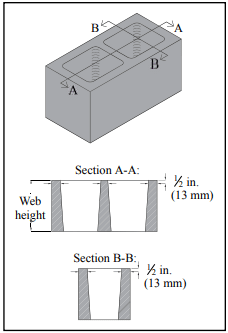

Unit dimensions are used: to verify that the overall length, width and height are within allowable tolerances; to calculate normalized web area and equivalent thickness; and to verify that face shell and cross web thicknesses meet the requirements of the appropriate unit specification (see Figure 1). Minimum face shell thickness is prescribed to address concerns such as ease of mortar placement, sufficient mortar coverage over joint reinforcement and resistance to lateral pressure from grouting. Minimum web thickness and area considerations include transfer of shear, flexural strength in the horizontal span, and resistance to tensile splitting of walls under compression.

Included in ASTM C140 since 2012 is testing to determine minimum normalized web area. Its purpose is to ensure that the unit has sufficient web material connecting the face shells. It replaces the equivalent web thickness criteria in previous versions of the standard. To determine the normalized web area, the minimum thickness and height of each web is measured and used to calculate the total web area of the unit. This total web area is divided by the nominal unit face area to determine normalized web area in in.²/ft² (mm²/m²).

Although not specified in ASTM C140 (ref. 1), the units set aside for absorption testing are typically used for measurement of unit dimensions, before the units are immersed in water. This way, the gross volume (determined from overall unit dimensions) and the net volume (determined from water displacement) for the units are both determined from the same set of test specimens.

Absorption

Absorption describes the amount of water a unit can hold when saturated. Absorption can be an indicator of the level of compaction of the concrete mix or of the volume of voids within a block. For a given mix design and manufacturing and curing process, variations in absorption can be an indication of deleterious materials in the mix, mixing quality, and/or compaction of the concrete mix, which also can indicate variations in compressive strength, tensile strength, durability, laboratory procedural problems, or other causes. Data collected during absorption testing is used to calculate absorption, density, net area, net volume and equivalent thickness.

Each unit is weighed a minimum of five times in this order: received weight; immersed weight; saturated surface dry weight; and oven-dry weight (at least twice). The saturated and immersed weights should always be determined following 24 to 28 hours of immersion and prior to oven drying the units.

Because the units are immersed in water and subsequently oven-dried during absorption testing, the units used for this determination should not be used for compression testing, the results of which are influenced by unit moisture content. Six units of identical size and configuration are therefore required for ASTM C140 testing—three for compression testing and three for absorption.

Compressive Strength

Compressive strength tests are used to ensure that concrete masonry units meet the minimum strength requirements of the applicable unit specification (see ref. 11). The unit compressive strength results may also be used to verify compliance with the specified compressive strength of masonry, f’m, when using the unit strength method (ref. 4, Article 1.4 B.2.b). Unit compression tests are easier and less expensive to perform than similar tests on masonry prisms, making the unit strength method the more popular.

Some of the critical areas of compression testing that are necessary to insure accurate testing include:

- Appropriate capping stations with stiff, planar plates with smooth surfaces.

- Compression machines with spherically seated heads and bearing plates of adequate planeness and thickness for the size of the specimen being tested. See TEK 18-01B (ref. 8) for details and an example.

- Proper specimen alignment within the testing machine (center of mass aligned with center of thrust).

For compressive strength determination, three specimens are tested. Wherever possible, full-sized units are used. However, certain modifications are permitted or required as follows:

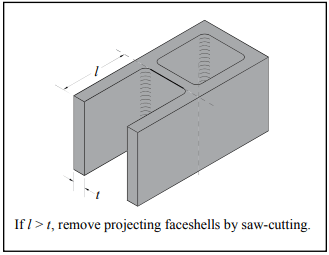

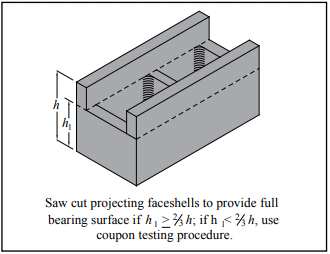

- Unsupported projections with a length exceeding the projection thickness must be removed by saw-cutting (see Figure 2). For units with recessed webs, the face shell projecting above the web is removed by saw-cutting to provide a full bearing surface over the net cross-section of the unit, as shown in Figure 3.

- When the size and/or strength of the unit exceeds the testing machine capacity, a specimen may be cut to conform to the testing machine capabilities. The resulting specimen, however, must contain an enclosed four-sided cell or cells without irregular face shells or webs.

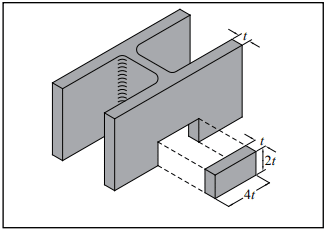

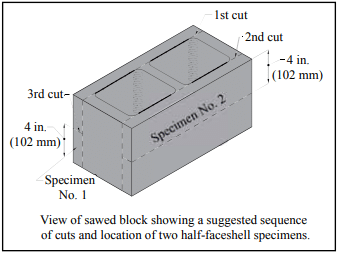

- If saw-cutting does not produce a test specimen complying with the above provisions, coupons may be saw-cut from the face shells (see Figure 4).

- For concrete roof paver units, cut three test specimens from three whole paver units to produce a strip of paver with the specimen height equal to its width. Where the paver has supporting ribs, cut the coupon perpendicular to the direction of the ribs, such that any bevelled or recessed surfaces are not included in the top or bottom edges of the specimen.

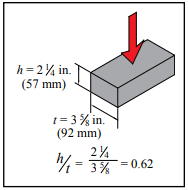

- For concrete brick, specimens are required to have an aspect ratio (height divided by least lateral dimension) of 0.6 ± 0.1 (see Figure 5).

The prepared specimens are then capped in accordance with ASTM C1552 (ref. 9) to provide a uniform and level bearing surface. After the specimen center of mass is located, the specimen is positioned in the testing machine such that the specimen’s center of mass is aligned with the machine’s center of thrust. All hollow units are tested with their cores in a vertical direction, except for special units intended for use with their cores horizontal. These special units and units that are 100% solid are tested in the same direction as intended for service. Further information on compressive strength testing is available in references 8 and 12.

Calculations

Using the data gathered in the preceding test methods, the following characteristics are determined: absorption, density, average net area, gross area, net and gross area compressive strengths, normalized web area and equivalent thickness.

Density, or unit weight, is described in terms of dry weight per cubic foot. It is determined from the saturated weight, immersed weight and oven-dry weight. Using these weights, the volume of concrete in a unit is readily determined and its density is the oven-dry weight divided by its net volume. Among the properties affected by density of concrete in a block are wall weight, building weight, thermal conductivity, heat capacity and acoustical properties.

Cross-sectional area is the basis for expressing compressive strength of concrete masonry units. Unit specifications require that block comply with a minimum net area compressive strength. Net area is described in terms of the percentage of solid material in the cross section, and is measured by the ratio of net volume of the unit to gross volume of the unit. Because water displacement is used to determine net volume, the net cross-sectional area represents the average net area of the unit.

Equivalent thickness is used to determine the fire resistance rating. It represents the average thickness of a hollow unit if the volume is configured into a solid unit of the same face dimension. It is determined by dividing the net unit volume by the unit face area.

DRYING SHRINKAGE, ASTM C426

ASTM C426, Standard Test Method for Drying Shrinkage of Concrete Masonry Units (ref. 2) is intended to evaluate the potential shrinkage characteristics of concrete masonry units due to moisture loss only. Note that concrete masonry may also shrink due to factors such as carbonation and temperature changes, which are not addressed by this test method (although temperature is standardized and corrected so as not to influence the results). This test measures unit length change from a totally saturated condition to an “equilibrium” condition at 17% relative humidity. This represents the potential shrinkage because the masonry is unlikely to encounter these extreme conditions under normal circumstances. The test results are used to determine concrete masonry crack control provisions.

Typically, it is not necessary to run shrinkage tests on units made with the same mix design but having different unit configurations. As long as there are no changes in materials, mix design, production methods or curing, ASTM C426 tests are required to be performed only once every two years, per ASTM C90 (ref. 13).

Test specimens are usually whole units with measurements taken on both faces. Alternatively, coupons may be cut from face shells, as illustrated in Figure 6. Gage plugs are mounted on the test specimens to facilitate length measurements.

This method requires the test specimens to be saturated for 48 hours, at which time the length is precisely measured and recorded. Specimens are then dried in an oven for 5 days. After drying, specimens are cooled and measured. Test specimens are then returned to the drying oven for periods of 48 hours until the length change is negligible.

PREFACED UNITS

For concrete masonry units with a smooth, resinous tile-like facing adhered to the unit, Standard Specification for Prefaced Concrete and Calcium Silicate Masonry Units, ASTM C744 (ref. 3) includes requirements and applicable test methods for the facing. The concrete masonry unit to which the facing is applied must comply with the applicable unit specification. Facing requirements include:

Resistance to crazing—Units are subjected to wetting and drying to demonstrate that the facing does not craze, crack or spall.

Resistance to chemicals—The facing must remain unchanged when subjected to the specified list of chemicals and exposure durations.

Adhesion—The facing must remain adhered to the unit when the unit is loaded to failure by an applied compression load.

Abrasion—The wear index of the facing must exceed 130 when the facing is subjected to a standard abrasion test (ASTM C501, ref. 5).

Surface burning—The flame spread and smoke density rating of the facing must not exceed 25 and 50, respectively, when tested in accordance with ASTM E84 (ref. 6).

Color tint & texture—The facing texture must remain unchanged and facing color difference must not exceed 5 Delta units (ref. 7) when subjected to an accelerated weathering test.

Soiling and cleansability—No more than a trace of stain may remain on the facing after cleaning when subjected to a specified list of marking substances.

REFERENCES

- Standard Test Methods for Sampling and Testing Concrete Masonry Units and Related Units, ASTM C140/C140M-14. ASTM International, 2014.

- Standard Test Method for Linear Drying Shrinkage of Concrete Masonry Units, ASTM C426-10. ASTM International, 2010.

- Standard Specification for Prefaced Concrete and Calcium Silicate Masonry Units, ASTM C744-14. ASTM International, 2014.

- Specification for Masonry Structures, TMS 602-13/ACI 530.1-13/ASCE 6-13. Reported by the Masonry Standards Joint Committee, 2013.

- Standard Test Method for Relative Resistance to Wear of Unglazed Ceramic Tile by the Taber Abraser, ASTM C501-84(2009). ASTM International, 2009.

- Standard Test Method for Surface Burning Characteristics of Building Materials, ASTM E84-14. ASTM International, 2014.

- Standard Practice for Calculation of Color Tolerances and Color Differences from Instrumentally Measured Color Coordinates, ASTM D2244-14. ASTM International, 2014.

- Evaluating the Compressive Strength of CM based on 2012IBC/2011 MSJC, TEK 18-01B. Concrete Masonry & Hardscapes Association, 2011.

- Standard Practice for Capping Concrete Masonry Units, Related Units and Masonry Prisms for Compression Testing, ASTM C1552-14. ASTM International, 2014.

- Standard Specification for Concrete Building Brick, ASTM C55-14. ASTM International, 2014.

- Concrete Masonry Unit Shapes, Sizes, Properties, and Specifications, CMU-TEC-001-23, Concrete Masonry & Hardscapes Association, 2023.

- Compressive Strength Testing Variables for CM Units, TEK 18-07, Concrete Masonry & Hardscapes Association, 2004..

- Standard Specification for Loadbearing Concrete Masonry Units, ASTM C90-14. ASTM International, 2014.