Concrete Masonry Cantilever Retaining Walls

INTRODUCTION

Using concrete masonry in retaining walls, abutments and other structural components designed primarily to resist lateral pressure permits the designer and builder to capitalize on masonry’s unique combination of structural and aesthetic features—excellent compressive strength; proven durability; and a wide selection of colors, textures and patterns. The addition of reinforcement to concrete masonry greatly increases the tensile strength and ductility of a wall, providing higher load resistance.

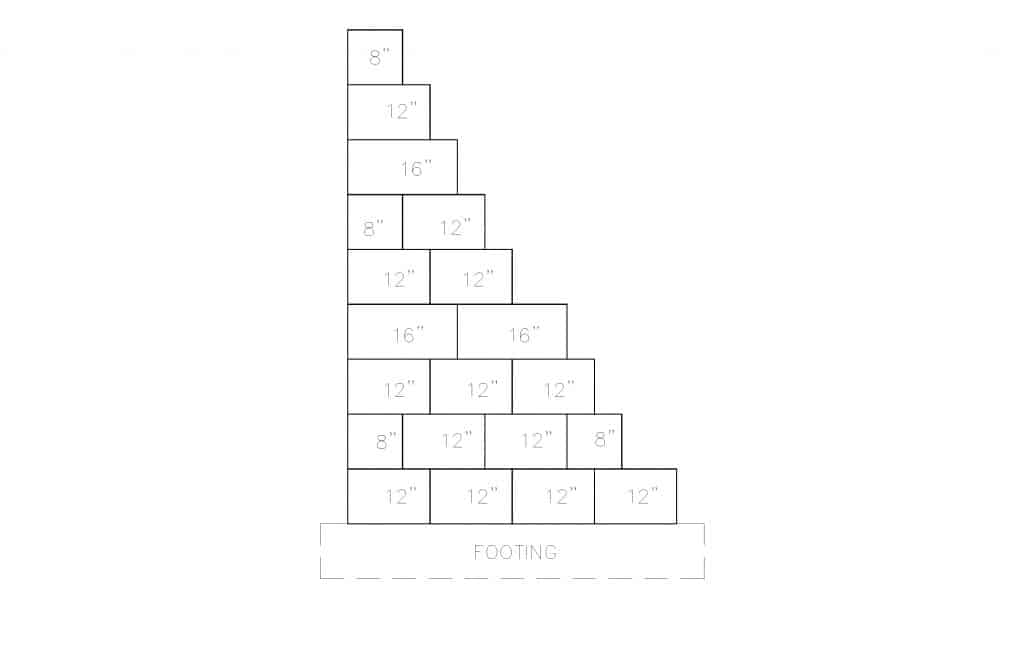

In cantilever retaining walls, the concrete base or footing holds the vertical masonry wall in position and resists overturning and sliding caused by lateral soil loading. The reinforcement is placed vertically in the cores of the masonry units to resist the tensile stresses developed by the lateral earth pressure.

DESIGN

Retaining walls should be designed to safely resist overturning and sliding due to the forces imposed by the retained backfill. The factors of safety against overturning and sliding should be no less than 1.5 (ref. 7). In addition, the bearing pressure under the footing or bottom of the retaining wall should not exceed the allowable soil bearing pressure.

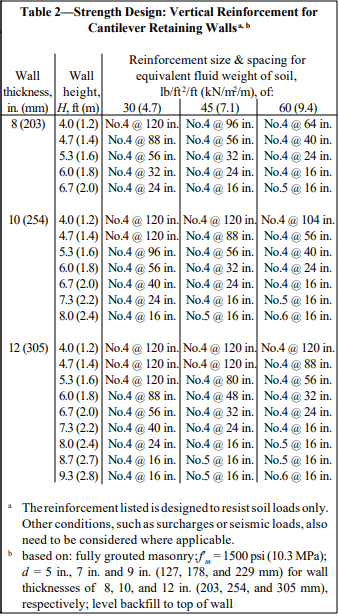

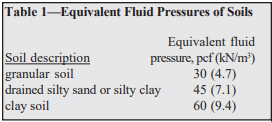

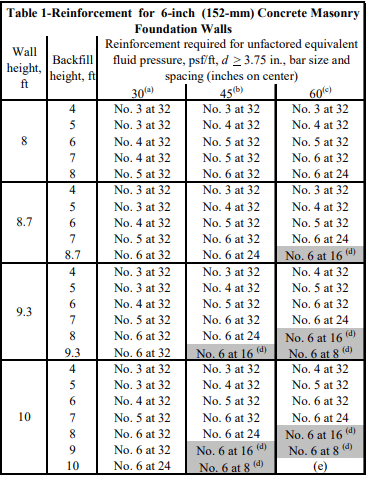

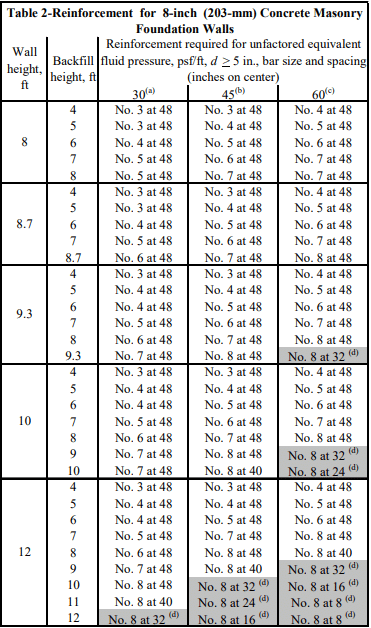

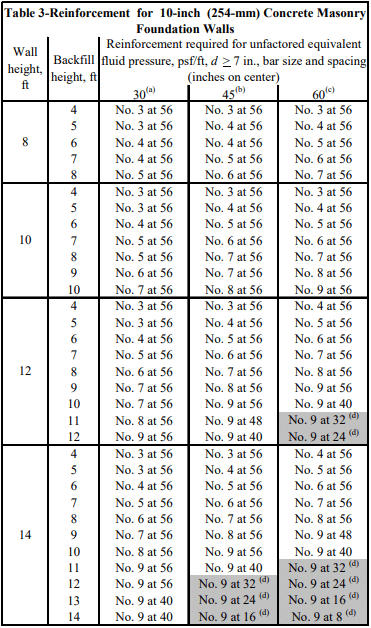

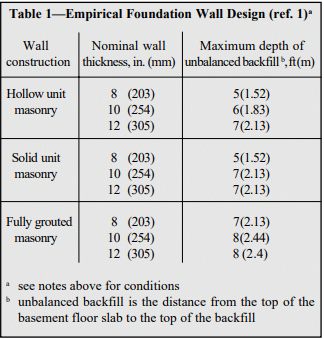

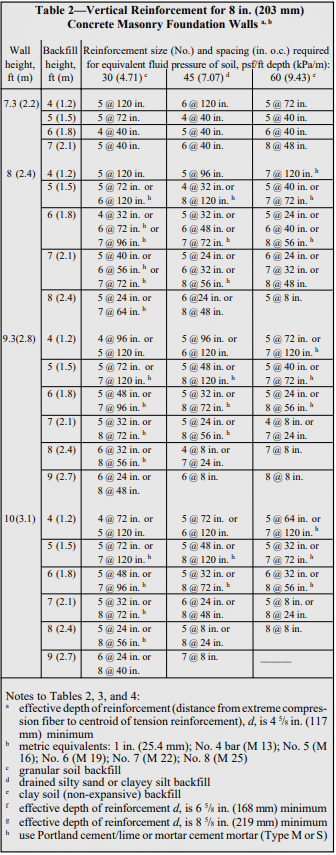

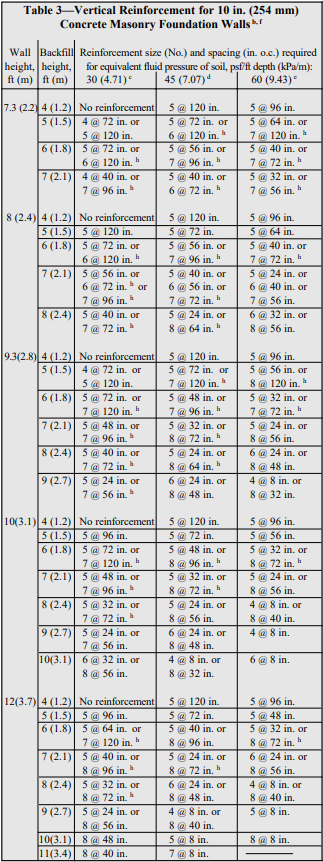

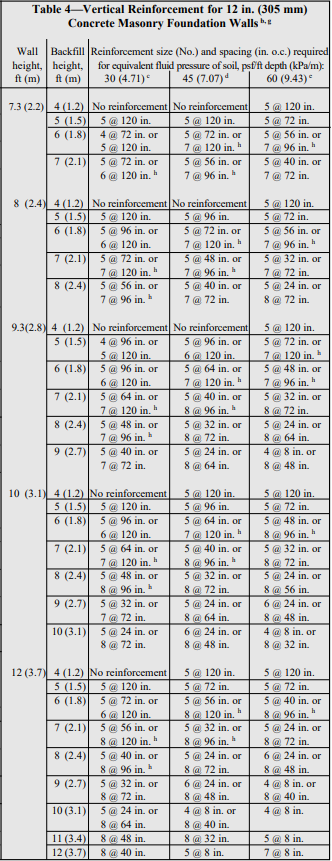

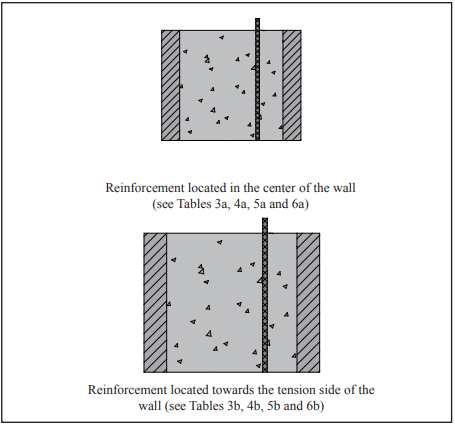

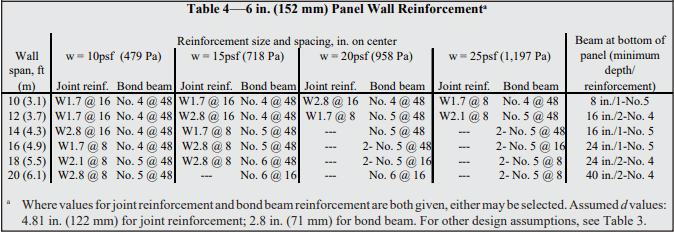

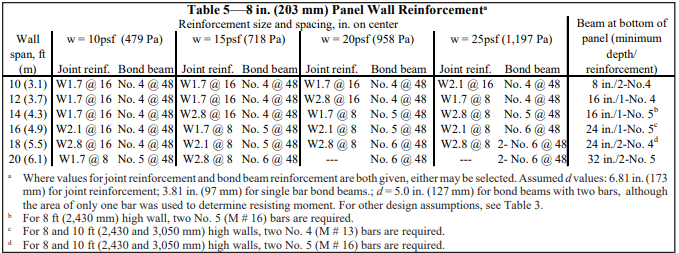

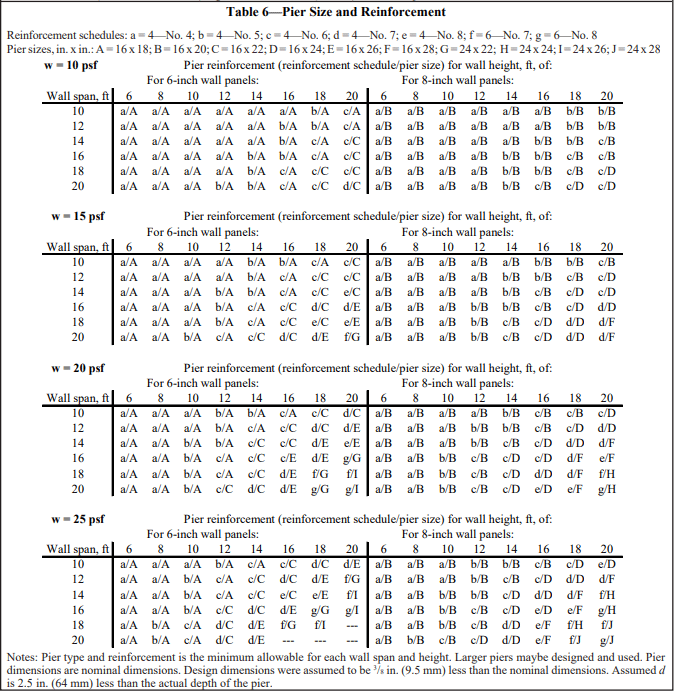

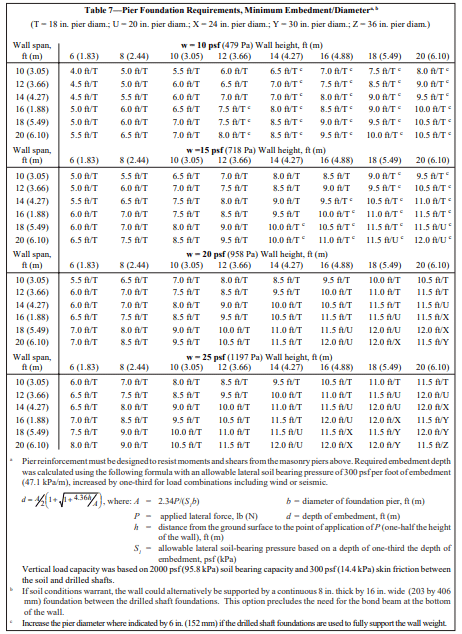

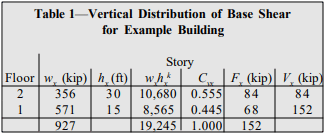

Recommended stem designs for reinforced cantilever retaining walls with no surcharge are contained in Tables 1 and 2 for allowable stress design and strength design, respectively. These design methods are discussed in detail in ASD of Concrete Masonry (2012 IBC & 2011 MSJC), TEK 14-07C, and Strength Design Provisions for Concrete Masonry, TEK 14-04B (refs. 5, 6).

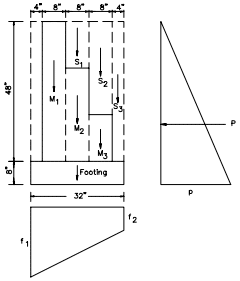

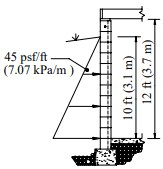

Figure 1 illustrates typical cantilever retaining wall detailing requirements.

DESIGN EXAMPLE

The following design example briefly illustrates some of the basic steps used in the allowable stress design of a reinforced concrete masonry cantilever retaining wall.

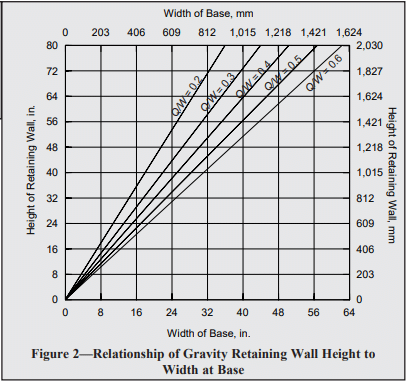

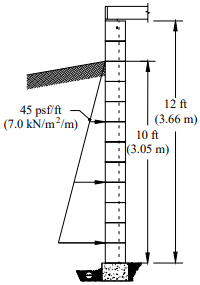

Example: Design the reinforced concrete masonry cantilever retaining wall shown in Figure 2. Assume level backfill, no surcharge or seismic loading, active earth pressure and masonry laid in running bond. The coefficient of friction between the footing and foundation soil, k1, is 0.25, and the allowable soil bearing pressure is 2,000 psf (95.8 kPa) (ref. 7).

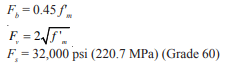

a. Design criteria:

Wall thickness = 12 in. (305 mm)

f’m = 1,500 psi (10.3 MPa)

Assumed weights:

Reinforced masonry: 130 pcf (2,082 kg/m³) (solid grout to increase overturning and sliding resistance)

Reinforced concrete: 150 pcf (2,402 kg/m³)

Required factors of safety (ref. 7)

F.S. (overturning) = 1.5

F.S. (sliding) = 1.5

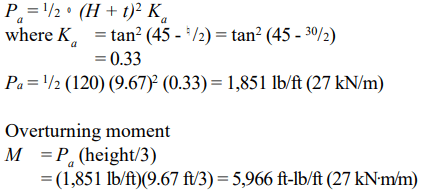

b. Rankine active earth pressure

c. Resisting moment (about toe of footing)

Component weights:

masonry: (0.97)(8.67 ft)(130 pcf) = 1,093 lb/ft (16 kN/m)

earth: (2.69)(8.67 ft)(120 pcf) = 2,799 lb/ft (41 kN/m)

footing: (1.0)(5.33 ft)(150 pcf) = 800 lb/ft (12 kN/m)

| Weight (lb/ft) | X | Arm (ft) | = | Moment (ft-lb/ft) | |

| masonry: | 1,093 | X | 2.67 | = | 2,918 |

| earth: | 2,799 | X | 3.98 | = | 11,140 |

| footing: | 800 | X | 2.67 | = | 2,136 |

| 4,692 | 16,194 |

| Total resisting moment | 16,194 ft-lb/ft |

| Overturning moment | – 5,966 ft-lb/ft |

| 10,228 ft-lb/ft (45.5 kN m/m) |

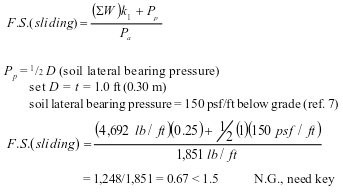

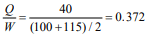

d. Check factors of safety (F.S.)

F.S. (overturning)

= total resisting moment about toe/overturning moment

= 14,670/5,966

= 2.4 > 1.5 O.K.

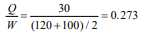

e. Pressure on footing

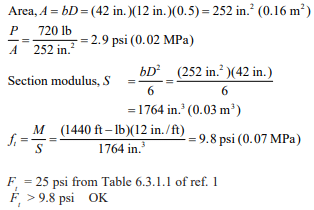

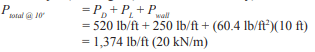

f. Determine size of key

Passive lateral soil resistance = 150 psf/ft of depth and may be increased 150 psf for each additional foot of depth to a maximum of 15 times the designated value (ref. 7). The average soil pressure under the footing is: ½ (1,356 + 404) = 880 psf (42.1 kPa).

Equivalent soil depth: 880 psf/120 pcf = 7.33 ft (2.23 m)

Pp = (150 psf/ft)(7.33 ft) = 1,100 psf (52.7 kPa)

For F.S. (sliding) = 1.5, the required total passive soil resistance is: 1.5(1,851 lb/ft) = 2,776 lb/ft (41 kN/m)

The shear key must provide for this value minus the frictional resistance: 2,776 – 1,248 = 1,528 lb/ft (22 kN/m).

Depth of shear key = (1,528 lb/ft)/(1,100 psf) = 1.39 ft (0.42 m), try 1.33 ft (0.41 m).

At 1.33 ft, lateral resistance = (1,100 psf) + (150 psf/ft)(1.33 ft) = 1,300 lb/ft (19 kN/m)

Depth = (1,528 lb/ft)/[½ (1,100 + 1,300)] = 1.27 ft (0.39 m) < 1.33 ft (0.41 m) O.K.

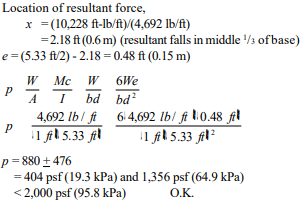

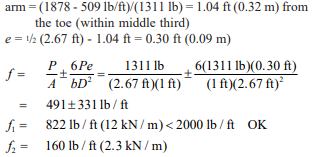

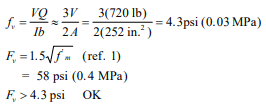

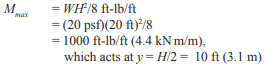

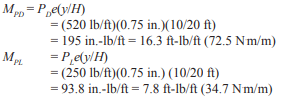

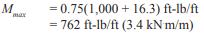

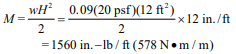

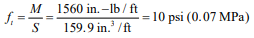

g. Design of masonry

Tables 1 and 2 can be used to estimate the required reinforcing steel based on the equivalent fluid weight of soil, wall thickness, and wall height. For this example, the equivalent fluid weight = (Ka)(º) = 0.33 x 120 = 40 pcf (6.2 kN/m³).

Using allowable stress design (Table 1) and the conservative equivalent fluid weight of soil of 45 pcf (7.1 kN/m³), this wall requires No. 6 bars at 16 in. o.c. (M #19 at 406 mm o.c.). Using strength design (Table 2), this wall requires No. 5 bars at 16 in. o.c. (M #16 at 406 mm o.c.).

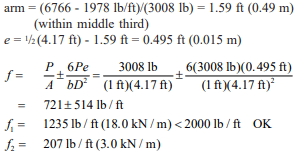

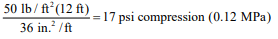

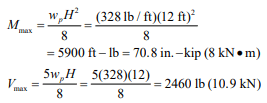

h. Design of footing

The design of the reinforced concrete footing and key should conform to American Concrete Institute requirements. For guidance, see ACI Standard 318 (ref. 2) or reinforced concrete design handbooks.

CONSTRUCTION

Materials and construction practices should comply with applicable requirements of Specification for Masonry Structures (ref. 4), or applicable local codes.

Footings should be placed on firm undisturbed soil, or on adequately compacted fill material. In areas exposed to freezing temperatures, the base of the footing should be placed below the frost line. Backfilling against retaining walls should not be permitted until the masonry has achieved sufficient strength or the wall has been adequately braced. During backfilling, heavy equipment should not approach closer to the top of the wall than a distance equal to the height of the wall. Ideally, backfill should be placed in 12 to 24 in. (305 to 610 mm) lifts, with each lift being compacted by a hand tamper. During construction, the soil and drainage layer, if provided, also needs to be protected from saturation and erosion.

Provisions must be made to prevent the accumulation of water behind the face of the wall and to reduce the possible effects of frost action. Where heavy prolonged rains are anticipated, a continuous longitudinal drain along the back of the wall may be used in addition to through-wall drains.

Climate, soil conditions, exposure and type of construction determine the need for waterproofing the back face of retaining walls. Waterproofing should be considered: in areas subject to severe frost action; in areas of heavy rainfall; and when the backfill material is relatively impermeable. The use of integral and post-applied water repellents is also recommended. The top of masonry retaining walls should be capped or otherwise protected to prevent water entry.

REFERENCES

- Building Code Requirements for Masonry Structures, ACI 530-05/ASCE 5-05/TMS 402-05. Reported by the Masonry Standards Joint Committee, 2005.

- Building Code Requirements for Structural Concrete and Commentary, ACI 318-02. Detroit, MI: American Concrete Institute, 2002.

- Das, B. M. Principles of Foundation Engineering. Boston, MA: PWS Publishers, 1984.

- Specification for Masonry Structures, ACI 530.1-05/ASCE 6-05/TMS 602-05. Reported by the Masonry Standards Joint Committee, 2005.

- ASD of Concrete Masonry (2012 IBC & 2011 MSJC), TEK 14-07C, Concrete Masonry & Hardscapes Association, 2004.

- Strength Design Provisions for Concrete Masonry, TEK 14-04B, Concrete Masonry & Hardscapes Association, 2008.

- 2003 International Building Code. International Code Council, 2003.

NOTATIONS

a length of footing toe, in. (mm)

B width of footing, ft (m)

d distance from extreme compression fiber to centroid of tension reinforcement, in. (mm)

e eccentricity, in. (mm)

F.S. factor of safety

f’m specified compressive strength of masonry, psi (MPa)

H total height of backfill, ft (m)

I moment of inertia, ft4 (m4)

Ka active earth pressure coefficient

k1 coefficient of friction between footing and foundation soil

M maximum moment in section under consideration, ft-lb/ft (kN⋅m/m)

Pa resultant lateral load due to soil, lb/ft (kN/m)

Pp passive earth pressure, lb/ft (N/m)

p pressure on footing, psf (MPa)

T thickness of wall, in. (mm)

t thickness of footing, in. (mm)

W vertical load, lb/ft (N/m)

x location of resultant force, ft (m)

º density of soil, pcf (kg/m³)

¤ angle of internal friction of soil, degreesDisclaimer: Although care has been taken to ensure the enclosed information is as accurate and complete as possible, NCMA does not assume responsibility for errors or omissions resulting from the use of this TEK.