Rolling Door Details for Concrete Masonry Construction

INTRODUCTION

Openings in concrete masonry walls utilize lintels and beams to carry loads above the openings. When openings incorporate rolling doors (also referred to as overhead coiling doors or coiling doors), wind loads on the door are transferred to the surrounding masonry through the door guides and fasteners.

In some instances, the rolling doors have been designed for specific wind load applications, and are heavily dependent on the structural integrity of the door jamb members as they are attached to building walls at jamb locations. This TEK discusses the forces imposed on a surrounding concrete masonry wall by rolling doors, and includes recommended details for jamb construction. Lintel design, to carry the loads imposed on the top of the opening, are covered in Allowable Stress Design of Concrete Masonry Lintels and Precast Concrete Lintels for Concrete Masonry Construction (refs. 1, 2).

LOADS EXERTED BY ROLLING DOORS

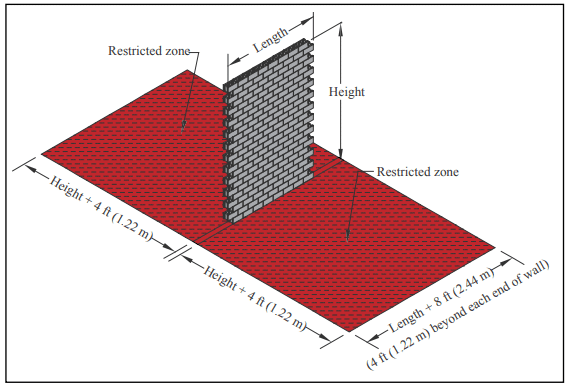

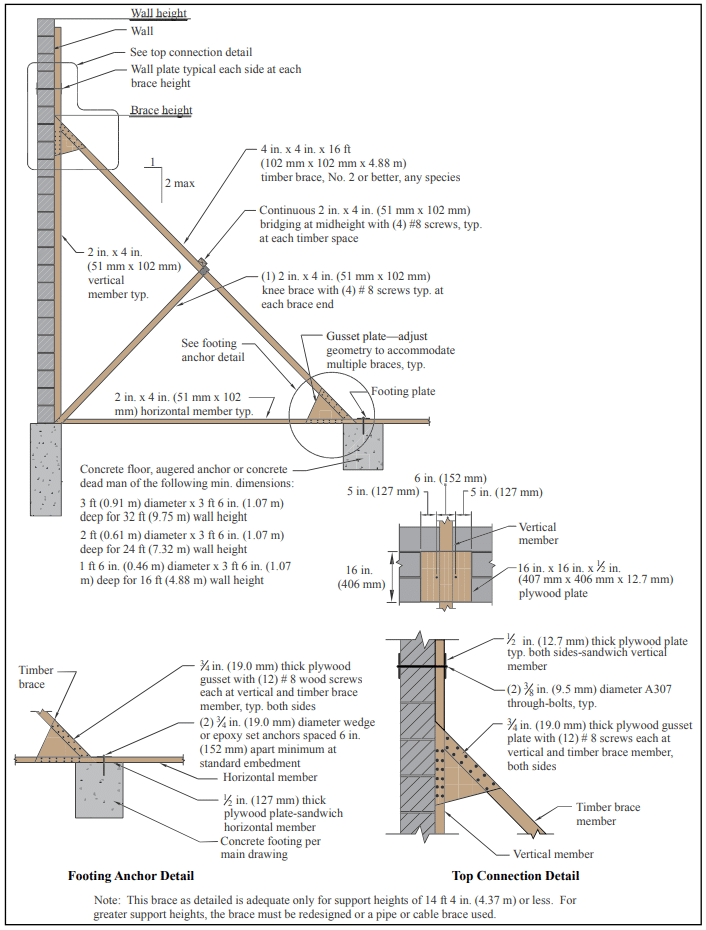

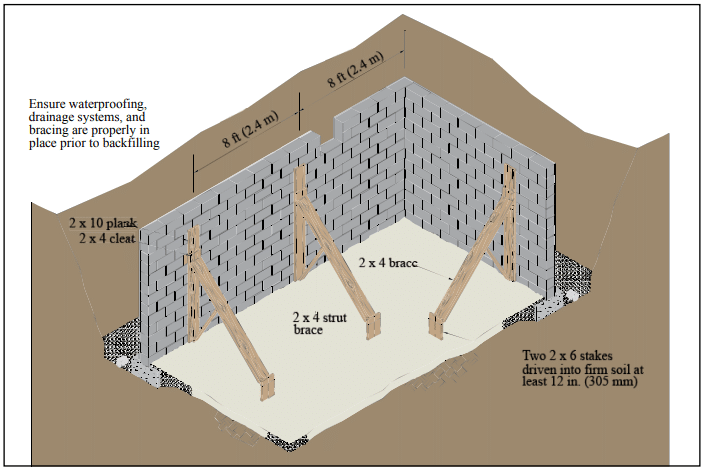

Architects and building designers should determine the loads that rolling doors exert on the wall around the opening. Dead loads include the weight of the door curtain, counterbalance, hood, operator, etc., that is supported by the wall above the opening. Live loads result from wind that acts on the door curtain. Rolling doors are available with windlocks, which prevent the door curtain from leaving the guides due to wind loading. On doors without windlocks, the only wind load force that the curtain exerts on the guides is normal to the opening. For doors with windlocks, there is an additional load parallel to the opening (see Figures 1 and 2 for face-mounted and jambmounted doors, respectively). This load is the catenary tension that results when the curtain deflects sufficiently to allow the windlocks to engage the windbar in the guide. This force acts to pull the guides toward the center of the opening. The door is exposed to a additive wind loads, from both inside and outside the building.

Calculating the parallel force involves several variables, the most prominent of which are the width of the opening and the design wind load. It is also important to note that the door must withstand both positive and negative wind loads. Including these forces in the design of the jamb and its supporting structure can help prevent a jamb failure and allow the building to fully withstand its specified wind load requirements. The rolling door manufacturer can provide a guide data sheet for quantifying the loads imposed by the overhead coiling doors due to the design wind load.

The following conditions need to be considered:

- The wall above the door opening must be designed to support the total hanging dead load. The face of wallmounted doors may extend above the opening for 12 to 30 in. (305-762 mm). The door guide wall angles must be mounted to the wall above the opening to support the door. When the door has a hood to cover the coiled door and counter-balance, some provision must be made to fasten the top of the hood and hood supports to the masonry wall. See also Fasteners for Concrete Masonry (ref.3).

- Reinforcement in jambs is recommended to adequately distribute the forces imposed by the door.

- Reinforcement locations should be planned such that the reinforcement does not interfere with expansion anchor placement.

ACCOMODATING MASONRY REINFORCEMENT AND DOOR FASTENERS

Rolling door contractors and installers sometimes encounter reinforcement in walls at locations where door jamb fasteners have been specified. Arbitrarily changing either the reinforcement location or the fastener location is not recommended, as either can negatively impact performance. Changing the door manufacturer’s recommended jamb fastener locations may reduce the structural performance of the rolling door or possibly void the fire rating.

The typical masonry jamb detail shown in Figure 3 indicates recommended vertical reinforcement locations for concrete masonry jambs to provide an area for the door fasteners. The detail shows a “reinforcement-free zone” to allow for fasteners of either face mounted or jamb-mounted rolling doors. The Door and Access Systems Manufacturers Association International (DASMA) recommends that vertical reinforcement should be within 2 in. (51 mm) of either corner of the wall at the jamb (ref. 4).

EXISTING CONSTRUCTION

Before installing fasteners in existing masonry construction, the following steps should be followed to locate the reinforcement, to avoid interference:

- If structural drawings are available, the project engineer should review the drawings to determine whether or not the jamb reinforcement locations conflict with the specified door jamb fastener locations.

- If the building’s structural plans are not available, either drill

representative “pilot holes” or use a device similar to an electronic stud locator to determine the steel reinforcement locations.

Once the steel reinforcement has been located, if it is concluded that the reinforcement will interfere with installing jamb fasteners, DASMA recommends that one of the following courses of action be taken:

- Consider an alternate door jamb mounting or door size to assure that the reinforcement will not interfere with jamb fasteners.

- If an alternate door jamb mounting or alternate door size cannot be accomplished, consult a structural engineer to determine a workable solution. One possible solution is to contact the door manufacturer to obtain an alternate conforming hole pattern for the mounting, which would not interfere with the existing reinforcement. Another solution may be to bolt a steel angle to the concrete masonry jambs, which allows the door guides to then be welded or bolted to the steel angle.

FIRE-RATED ROLLING DOOR CONNECTIONS

When installed in a fire-rated concrete masonry wall, rolling steel fire doors must meet the code-required fire rating corresponding to the fire rating of the surrounding wall. For fire testing, the doors are mounted on the jambs of a concrete masonry wall intended to replicate field construction. The fire door guides must remain securely fastened to the jambs and no “through gaps” may occur in the door assembly during the test. Figure 4 shows a representative jamb construction and guide attachment details for a four-hour fire rated assembly. Note that guide configurations and approved jamb construction will vary with individual fire door manufacturer’s listings. Consult with individual manufacturers for specific guide details and approved jamb constructions.

REFERENCES

- Allowable Stress Design of Concrete Masonry Lintels

Based on 2012 IBC/2011 MSJC, TEK 17-01D, Concrete

Masonry & Hardscapes Association, 2011. - Precast Concrete Lintels for Concrete Masonry

Construction, TEK 17-02A, Concrete Masonry &

Hardscapes Association, 2000. - Fasteners for Concrete Masonry, TEK 12-05, Concrete

Masonry & Hardscapes Association, 2005. - Metal Coiling Type Door Jamb Construction: Steel

Reinforcement In Masonry Walls, TDS-259. Door and

Access Systems Manufacturers Association International,

2005. - Architects and Designers Should Understand Loads

Exerted By Overhead Coiling Doors, TDS-251. Door and

Access Systems Manufacturers Association International,

2005. - International Building Code 2003. International Code

Council, 2003. - International Building Code 2006. International Code

Council, 2006. - Common Jamb Construction for Rolling Steel Fire Doors:

Masonry Construction—Bolted and Welded Guides, TDS- - Door and Access Systems Manufacturers Association

International, 2005. - Steel Reinforcement for Concrete Masonry, TEK 12-04D,

Concrete Masonry & Hardscapes Association, 2006.