Joint Sealants for Concrete Masonry Walls

INTRODUCTION

Successfully sealing joints, such as control joints and around door jambs and window frames, in concrete masonry walls depends on the overall design and construction of the entire building envelope. Movement joints (also called control joints) are needed in some concrete masonry walls to accommodate drying shrinkage, thermal movements, and movements between different building components. Movement joints, joints around fenestration, doors and penetrations, and isolation joints (joints at dissimilar material interfaces) rely on joint sealants to help preserve the overall weather-tightness of the building envelope. In addition, properly sealed joints may be required to meet a specified fire resistance rating or sound transmission class.

The sealant’s primary role is to deform as the joint moves, maintaining the seal across the joint. Most joint sealants are field-applied (as opposed to preformed). For instance, a raked-out mortar joint or open movement joint may receive sealant from a gun-squeezed cartridge, typically applied over a backup material.

This TEK provides a basic overview of joint sealants, installation guidelines to help ensure longevity, and recommended maintenance procedures, based primarily on ASTM C1193, Standard Guide for Use of Joint Sealants (ref. 1) and ASTM C1472, Standard Guide for Calculating Movement and Other Effects When Establishing Sealant Joint Width (ref. 2). This TEK does not address adhesives.

For optimum performance, the sealant must be properly applied to a well-constructed joint. For example, joints that are too thick relative to the width may cause failure of even the best sealant. Detailed information on control joint design and construction is available in CMU-TEC-009-23 (ref. 3).

JOINT SEALANTS AND RELATED MATERIALS

Control joints in concrete masonry construction are classified as butt-joints, where the sealant is exposed to cyclical tension and compression as the joint expands and contracts. Therefore, control joint sealants should be able to maintain their original shape and properties under these conditions. In addition, joint sealants should be impermeable, deformable to accommodate the joint movement, and be able to adhere to concrete and masonry materials or be used with an appropriate primer. The use of primers has been reported to improve bond as well as watertightness at the joint. Because many factors influence a wall’s water penetration resistance, the reader is referred to TEK 19-02B, Design for Dry Single-Wythe Concrete Masonry Walls (ref. 4) for more complete information.

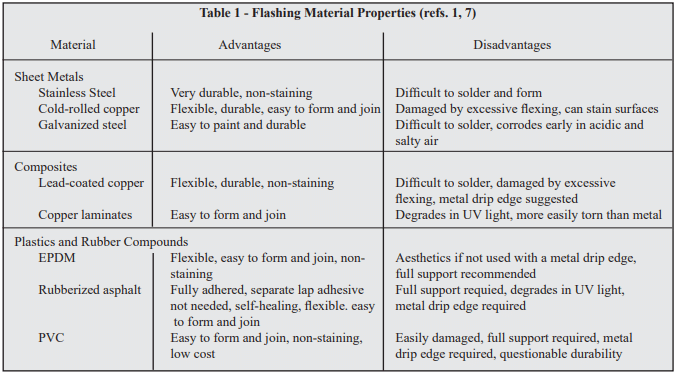

Some variables to consider when selecting a joint sealant are the sealant’s: joint movement capability (typically reported as two percentages, one for elongation and another for compression), time to set-up/cure, adhesion/bond strength to concrete masonry or other substrates, hardness, tensile strength, durability, expected life in service, ease of installation, primer requirements, application temperature range, paintability, warranty requirements, and sag-resistance. Materials that dry out rapidly and/or do not effectively bond to masonry, such as most oil-based caulks, are generally not recommended for use as concrete masonry joint sealants.

In-service conditions for the particular application must also be considered. For example, for joints that are not exposed to the weather, aesthetic factors such as available colors may be more important than the weather-resistance of the joint. Other applications may require properties such as chemical or fire resistance.

In short, no single sealant will meet the requirements of every application. The following sections briefly describe the most common materials used for concrete masonry joints.

Masonry Joint Sealants

Sealants must comply with ASTM C920-11 Standard Specification for Elastomeric Joint Sealants (ref. 6). Sealants used for concrete masonry joints and at penetrations in concrete masonry walls may be polyurethanes, polysulfides, acrylics, silicones, or even modified blends of each. These sealant materials tend to have:

- high resistance to aging and weathering,

- good resistance to low-temperature hardening,

- moderate resistance to age-related hardening,

- high resistance to indentation,

- low shrinkage after installation, and

- nonstaining properties.

Backup Materials

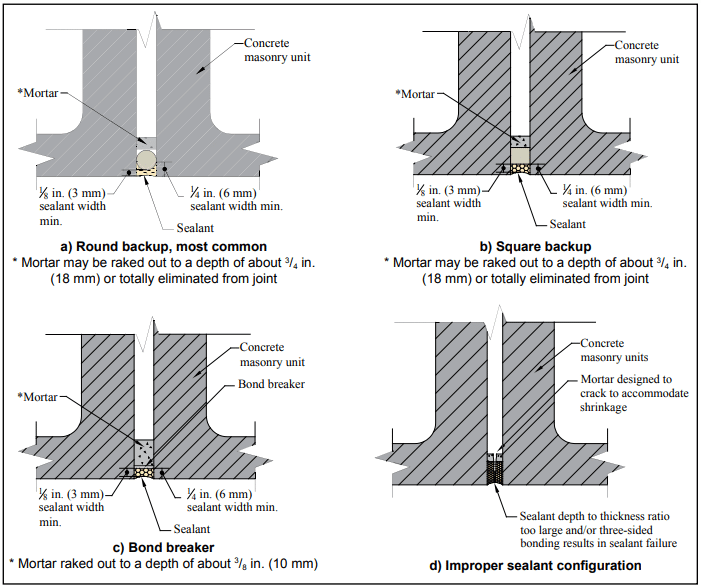

Backup materials are used to: restrict the sealant depth, support the sealant, facilitate tooling, and help resist indentation and sag. They may also serve as a bond breaker, preventing the sealant from adhering to the back of the joint. Backup materials for concrete masonry joints are commonly flexible foams, which are compressed into the joint using hand tools (see Figures 1a and 1b).

Backup materials for control joints must be compressible to accommodate masonry expansion (joint shrinkage), and must recover when the masonry shrinks (joint expands). Because the backup also needs to maintain contact with both joint faces when the joint expands, it is compressed when initially installed. Closed-cell backups should be sized 1 ¼ to 1 ⅓ the joint width, so they are compressed 25% to 30% when placed in the joint. Open-cell backups, which are less stiff than closed-cell, should be sized 1 ½ times the joint width, so they are compressed about 50% of their undisturbed width when installed.

Bond Breakers

Bond breakers prevent three-sided adhesion of the sealant (i.e. from adhering to the back of a raked joint or to the backup), allowing the sealant to freely deform in response to building movements (see Figure 1c). Because many backup materials act as bond breakers, a separate bond breaker material is not always required. When it is, polyethylene tape, butyl tape, coated papers and metal foils can be used as well as polyurethane, polyethylene and polyolefin foams. Liquid-applied bond breakers are not recommended because of the likelihood of contaminating the sealant adhesion surface.

Primers

Primers, applied to the joint surfaces prior to sealant installation, are sometimes recommended to improve the sealant’s bond strength. In addition, some primers can tolerate application to damp masonry surfaces.

Check the sealant manufacturer’s recommendations for the particular sealant under consideration to determine whether or not a primer should be used on a masonry substrate. To ensure the primer and sealant will be compatible, use the primer recommended by the sealant manufacturer for the sealant being used.

Primer is applied by brush, roller or spray, and typically must dry or cure before sealant application. The recommended elapsed time between primer application and sealant application varies with type of primer, temperature and humidity.

JOINT SEALANT INSTALLATION

Like most materials, joint sealants should be installed in accordance with manufacturer’s instructions. Elements that are due special consideration, such as sealant depth and surface preparation are discussed in more detail below.

It is typically recommended that joint sealants not be applied during rain or snow, and that the masonry be clean and dry at installation. Installation temperature, i.e., the temperature of the masonry when the sealant is applied, may also be a consideration in some cases. Sealants installed at very low temperatures undergo compression as the wall warms up to the mean temperature, while a sealant installed at a high temperature is placed in tension at the mean temperature. For these reasons, it is desirable to have the installation temperature close to the mean annual temperature, although an in- stallation temperature range of 40° to 90°F (4.4 to 32.2°C) is generally considered acceptable for most applications, unless otherwise specified by the sealant manufacturer (ref. 6). Note that the masonry surface temperature may greatly exceed the ambient air temperature, especially on dark-colored and/or south- and southwest-facing walls in the sun.

Sealant Width and Depth

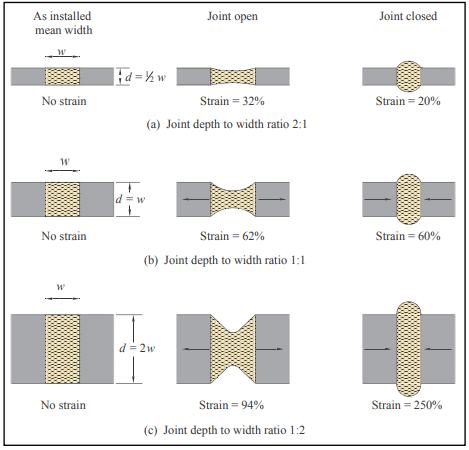

Sealant shape factor refers to the mean width versus mean depth of the sealant as installed in the joint. This ratio is important because it affects the amount of strain the sealant is exposed to as the joint moves, as well as the amount of sealant required to fill the joint (see Figure 1d). Sealants exposed to less strain can typically be expected to have a longer life, all other factors being equal. As illustrated in Figure 2, wider and shallower sealant profiles generally reduce strain and require less sealant.

In the field, sealant shape factor is controlled by varying the depth of the sealant, because the width of the joint is fixed at that point. The depth of sealant in the joint is typically controlled via the use of a backup material. Sealants that have a higher depth to width ratio tend to stretch more readily with joint movement, whereas with lower ratios the tendency is for the sealant to tear when subjected to movement. In general, for joint widths from ¼ to ½ in. (6 to 13 mm) the joint depth should be no more than the width of the joint. After the sealant is tooled, the minimum thickness of the sealant at the midpoint of the joint opening should not be less the ⅛ in. (3 mm) and the sealant adhesion dimension no less than ¼ in. (6 mm) (refs. 1, 2). The required thicknesses also should be verified with the sealant manufacturer.

Joint Preparation

For all control joints, mortar should be raked out of the vertical joints on both sides of the panels. The mortar should be raked out at least ¾ in. (19 mm) to allow for a backup material and sealant (⅜ in. (9.5 mm) if no backing is used). This also assures a plane of weakness at the control joint. Mortar in the control joint may also be totally omitted to ensure freedom of movement.

Proper surface preparation prior to sealant installation improves bond between sealant and masonry, and minimizes adhesion failures. Follow the sealant manufacturer’s recommendations regarding cleaning and/or priming the concrete masonry surface prior to applying sealant.

Backup materials must be installed to the proper depth in the joint to control the depth of sealant. Tools for placing backer materials can help ensure correct placement. Any tools used for placement should have a smooth surface adjacent to the backup, to avoid puncturing or otherwise damaging the backup material during placement.

Applying Sealant

Sealants may be either single- or multi-component. Multi-component sealants require thorough mixing, in accordance with the manufacturer’s instructions, to ensure uniform curing and to avoid over-mixing. Once mixed, the sealant has a limited pot life, so batch sizes should be matched to what can be installed within the pot life.

Masonry joint sealants are typically installed using a common caulk gun, with a tip the same size as the width of the joint. The caulk gun should be held at an angle of about 45° to the wall face, and moved slowly and consistently. Filling joints from bottom to top helps avoid trapping air as the sealant is placed.

Immediately after the joint is filled, the sealant should be tooled to a concave shape. Tooling helps ensure intimate contact between the sealant and masonry, consolidates the sealant, provides a concave profile and improves the appearance of the joint. The hour-glass shape shifts peak stresses away from the adhesion surface and to the middle of the sealant joint during joint movement. Most sealant manufacturers recommend dry-tooling for the best results.

MAINTENANCE

Properly maintained joint sealants will help maintain the water penetration resistance of the building envelope. Sealant materials cannot be expected to have the same life as a masonry building. For this reason, the sealant condition should be inspected on a regular basis, perhaps when the facade is cleaned, and repairs made as needed. Manufacturer’s recommendations should be used as a guideline to estimate sealant life. However, sealant life will vary greatly with exposure and the quality of the initial installation.

Because joint sealant adheres better to properly prepared surfaces, the old or deteriorated sealant should be completely removed from the joint and the joint cleaned prior to reapplication. Minor repairs can be made by cutting out the defective area and reapplying sealant of the same type. Sealants can be removed using a sharp knife to sever the sealant from the masonry. Although some manufacturers recommend more aggressive cleaning methods, such as sand-blasting or grinding, care should be taken when using these methods. For more detailed information on sandblasting, see TEK 08-04A, Cleaning Concrete Masonry, (ref. 6).

Once the joint is properly prepared, sealant can be installed as described above for new construction.

REFERENCES

- Standard Guide for Use of Joint Sealants, ASTM C1193-13. ASTM International, 2013.

- Standard Guide for Calculating Movement and Other Effects When Establishing Sealant Joint Width, ASTM C1472-10. ASTM International, 2010.

- Crack Control Strategies for Concrete Masonry Construction, CMU-TEC-009-23, Concrete Masonry & Hardscapes Association, 2023.

- Design for Dry Single-Wythe Concrete Masonry Walls, TEK 19-2B, Concrete Masonry & Hardscapes Association, 2012.

- Standard Specification for Elastomeric Joint Sealants, ASTM C920-11. ASTM International, 2011.

- Cleaning Concrete Masonry, TEK 8-4A. National Concrete Masonry Association, 2005.