Characteristics of Concrete Masonry Units With Integral Water Repellent

INTRODUCTION

A concrete masonry unit’s characteristics are a function of the properties and proportions of the materials used, as well as the manufacturing processes. The unit characteristics do not singularly define the characteristics and performance attributes of a concrete masonry wall, but they certainly play a significant role in influencing those attributes. When used as part of a breathable exterior wall for an inhabited structure, or as a barrier for any conditioned or protected space, concrete masonry is expected to contribute to the water penetration resistance and moisture control of the wall assembly. Current model building codes include provisions intended to ensure that exterior walls provide adequate weather protection for the building (ref. 1).

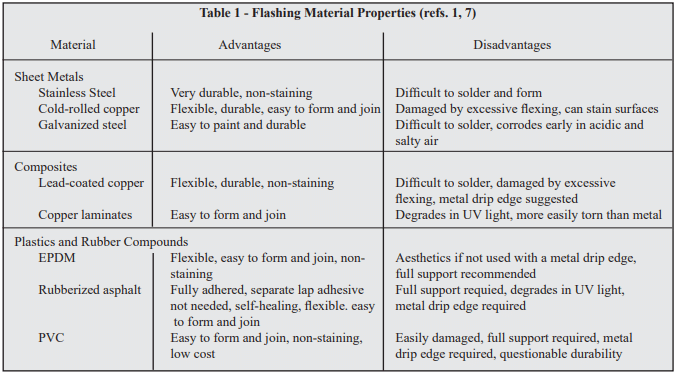

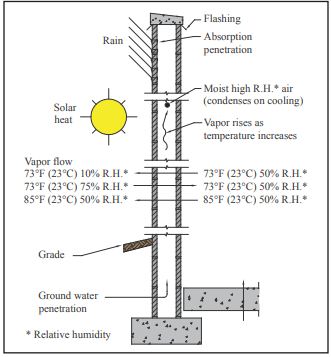

Design of concrete masonry walls to mitigate or control moisture migration includes many considerations beyond the characteristics of the concrete masonry unit, such as flashing, weeps, workmanship, mortar or grout characteristics, vents, coatings, vapor barriers, air barriers, temperature differences, and accommodation of differential movement, plumbing and roof leaks, as well as other considerations. The potential for condensation, whether at the wall’s interior surface, weather-exposed surface, and/or interior of the wall, should also be considered. Proper design and construction of concrete masonry, considering all of these elements, is critical to the water resistant performance of the wall system. These topics are addressed in References 2 through 7 and in other literature sources.

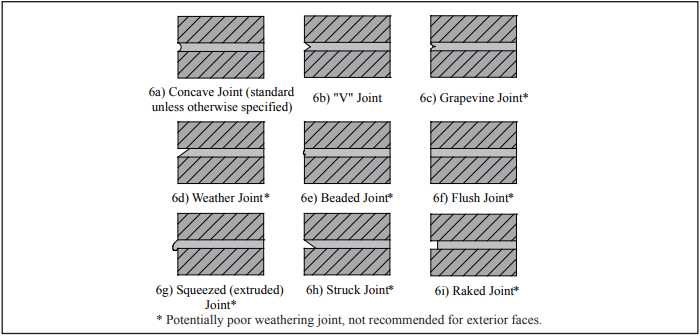

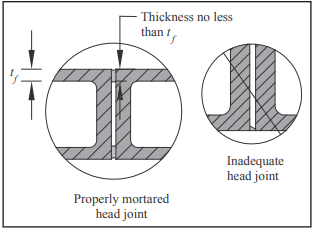

Mortar joints are especially critical to a wall’s water penetration resistance. Achieving good bond between the mortar and the unit surfaces is essential and is largely influenced by the mortar material itself, tooling procedures, and joint profile as well as by the configuration of the concrete masonry unit. Ribbed units, for example, make it difficult to adequately tool the mortar joints. Reducing mortar’s absorption characteristic is also important for achieving success in moisture control in a concrete masonry wall. This can be achieved using integral water repellent admixtures in the preparation of the mortar.

While all of the aforementioned aspects significantly affect wall performance, this TEK focuses specifically on evaluating the water penetration resistance characteristics of concrete masonry units and their role in contributing to control of moisture in the wall.

THE ROLE OF CONCRETE MASONRY UNITS

The concrete masonry unit’s role and contribution to the concrete masonry wall assembly’s water penetration resistance depends in part on how the units are used in the design. The unit characteristic requirements for contributing to success of the exterior wall may vary depending on the design of the masonry wall in which it is used. For example, the role of concrete masonry units is more critical relative to moisture control when they are part of a weather-exposed surface or exterior wall assembly for a protected and conditioned building than if they are used as an interior wall.

There are three primary forces influencing moisture control of a concrete masonry wall: positive or negative air pressures created by the weather or building ventilation systems, internal moisture absorption and/or adsorption through the matrix of the concrete material, and condensation/evaporation. For the purposes of this discussion, absorption is considered to relate to the cementitious material’s attraction to or affinity for water at the molecular level. Generally speaking, mortar tends to have a much greater affinity for water than does a concrete masonry unit. Adsorption is the affinity of water at the individual surfaces of the cementitious materials. For instance, capillary pressure creates the tendency for water to migrate into a porous object along the surfaces of the interconnected voids, such as a sponge placed in very shallow water. The same tendency may be observed in a mortar joint or an untreated concrete masonry unit due to interconnected voids.

When units are used on a building exterior, it is desirable to limit moisture migration through the first barrier of defense at the wall surface. Wind driven rain can be a significant cause of water breaching a mortar joint, the front face shell of a single wythe wall, or a veneer unit. These weather-induced positive pressures can create a challenge to barrier defenses. As a driving force, they are highest at the surface of the masonry and rapidly diminish a few inches into the mortar joint, the unit, or into the cavity of a drainage wall.

Water repellency characteristics of concrete masonry units can be defined by their contribution to barrier defenses at the surface of the wall (which will help limit the effect of the positive pressure of wind driven rain), by their ability to limit the potential for absorbing and adsorbing moisture through their matrix, and by their contribution to controlling condensation.

PERTINENT UNIT CHARACTERISTICS

Barrier defenses in concrete masonry units can be provided at the surface as well as within the mass of the concrete layer. Surface protection can be enhanced by post-applied breathable materials, external coatings and wall coverings. When coatings are used, the most important characteristic of the unit may be its compatibility with the type of coating used. Some clear sealers and certain paints may not be suitable for a particular concrete masonry unit since some coatings may not be able to bridge open pores or fill all surface irregularities or textures. For example, the proper performance of stucco relies on a rougher and more open unit surface texture of the concrete masonry unit to ensure adequate mechanical bonding.

Beyond the unit’s exterior surface compatibility with the type of breathable post-applied material, coating or wall covering used, if any, an important consideration is the characteristics of the concrete used to produce the unit. The water penetration resistance of concrete is determined by the characteristics of the matrix and its resistance to absorbing moisture. The properties and proportions of the raw materials used to produce the units and the manufacturing procedures employed influence the water penetration resistance of those units. For example, a greater volume of interconnected voids within the unit may provide an easier path for moisture migration. Alternatively, reducing the volume of voids, such as by increasing the unit compaction, may limit moisture movement through the unit. Aggregate type and gradation, cement to aggregate ratio, mix water content, alkalinity, machine compaction, curing processes, and plasticizing and integral water repellent admixtures are some of the parameters that can have an influence on water repellency characteristics.

INTEGRAL WATER REPELLENTS

Integral water repellent admixtures can be used in the mix design of the concrete masonry unit during production to limit a unit’s tendency to absorb moisture through its matrix. Integral water repellent admixtures are usually polymeric products that utilize hydrophobic materials to significantly reduce the absorption characteristics of the concrete. Without these admixtures, even those units with excellent compaction will absorb some moisture through the concrete matrix. Integral water repellents significantly limit absorption by changing the chemistry of the matrix, which may include coating the pores in the concrete with a hydrophobic material that reduces the chemical affinity for water. Thus, concrete masonry units with integral water repellents are positioned to repel water rather than automatically allowing it to migrate through the unit. However, use of integral water repellent admixtures alone does not assure a water-resistant unit. Care must still be taken in production as discussed above to reduce the volume of interconnected voids that will permit moisture migration via other forces, such as wind or gravity.

An advantage of integral water repellent admixtures is that they remain a permanent part of the concrete matrix. Unlike post-applied products, integral water repellent treatments require less maintenance since they are more durable, and they are active throughout the whole concrete matrix and not just at the surface. In addition, integral water repellents can reduce efflorescence by reducing water migration through the concrete masonry (including latent water introduced to the system from grout or mortar).

When integral water repellents are used in concrete masonry units, it is important that the same or a compatible admixture be used in the mortar as well in accordance with manufacturer’s recommendations. Failure to use an integral water repellent admixture in the mortar may compromise the water repellency characteristics of the wall.

EVALUATING UNIT WATER REPELLENCY

The water repellency characteristics of a concrete masonry unit can be evaluated using simplistic field methods or more involved laboratory test methods. Three methods are described briefly below, and in more detail in the referenced published industry test methods (refs. 8, 9, 10).

All of these tests are suitable for evaluating units to be used in wall construction. It is important that field testing, if considered necessary, be conducted prior to wall construction since most of these tests can not be accurately performed on a constructed wall surface. For instance, small amounts of mortar left on the surface of a unit even after cleaning, as well as the cleaning techniques themselves, may alter the surface characteristics of the unit relative to its as-delivered condition. Similarly, water introduced into the system from grout or mortar (water of latency) and in turn absorbed into the unit may change the unit’s characteristics. Before, after, or during construction, accumulated dust or pollution may also alter the surface characteristics. When water repellency characteristics are evaluated prior to unit placement, any unexpected results from field testing can be addressed in a timely manner using the default laboratory test methods described below.

Water Bottle and Water Droplet Tests

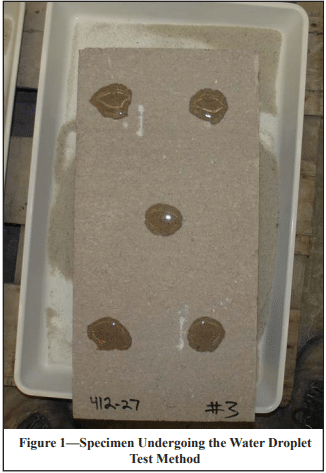

The water bottle and water droplet test methods (ref. 8) can be effective as a first pass evaluations of water repellency. The water droplet method is typically conducted on individual units in a horizontal position as shown in Figure 1 (90 degrees to the “as laid” or construction orientation), but as a variation the water bottle test can also be conducted on units placed in a vertical (“as laid”) orientation. Typically, a concrete masonry unit manufactured with an integral water-repellent admixture will be able to support at least three out of the five water droplets for a period of five minutes or more.

At the immediate surface of the concrete masonry unit, the effectiveness of an integral water repellent may diminish over time due to exposure to elements such as dirt, contaminants and UV light. The water repellency characteristics of the concrete just below the surface, however, remain unchanged and provide continuing protection. Therefore, while the water droplet test is rather reliable for identifying a sufficient level of water repellency, it may not be a good indicator of poor water repellency. In other words, if a unit fails to support a droplet of water, the unit should not be considered inadequate, but rather should be taken to a laboratory for further testing using the spray bar and water uptake methods.

If the unit is already installed in the wall, the water bottle test can be used to evaluate the unit. If water applied to the face of the unit is not absorbed immediately, but rather freely runs down the surface of the unit, it likely has sufficient water repellency. Again, if the water is absorbed at the surface, it can not be assumed that the unit does not have sufficient water resistance. Water can be sprayed on a larger wall surface area to determine if isolated units appear to have significantly higher absorption characteristics, since these may appear to have a darker surface color as a result of absorbed water. However, remember that conclusions based upon any field testing, especially on units installed in construction, are not definitive relative to water repellency determinations.

Spray Bar Test

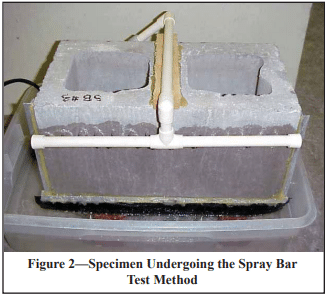

A spray bar test (ref. 9) is a good method to evaluate a unit’s ability to limit absorption as well as verify its effectiveness as a barrier against free moisture migrating through pinholes in the unit face. This laboratory test requires relatively inexpensive equipment and can be conducted in a single day. A spray bar is attached to the unit such that it applies a steady stream of water onto its face (see Figure 2). The inside of a hollow unit is visually inspected to assess if and how moisture has migrated through the front face shell.

Moisture may be present on the interior as dampness that can be seen on the inside surface of the front face shell, on the center or end webs, or even on the interior or exterior surfaces of the back face shell. Moisture may also be observed on the inside of the front face shell from “pinholes.” Pinholes are locations where water has found a path through the face shell to the interior of the unit. Free water will appear as a droplet and may eventually trickle down the inside of the front face shell. A good water repellent unit will limit moisture migration in both forms: dampness and pinholes. If a unit allows an excessive amount of water to migrate through the unit, the type of failure can give an indication of the corrective action that should be taken by the producer. Excessive dampness, for example, may indicate that additional integral water repellent admixture or process adjustment is needed. Excessive pinholes may indicate that an adjustment to the aggregate blend and/or increased compaction may be necessary to reduce the volume of interconnected voids in the unit.

Water Uptake Test

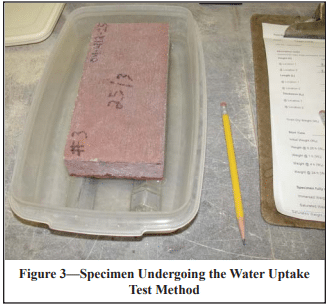

Another good method for evaluating a unit’s resistance to moisture migration is the water uptake test (ref. 10). The test involves placing an oven-dried unit face down (non-split side) in ⅛ in. (3 mm) of water and measuring the water absorption by means of its weight gain over time.

While the water uptake test may be very good at distinguishing between the levels of resistance to absorption uptake, it will not indicate compaction or other flaws that might result in pinholes. Therefore, it is recommended that the results of this test be used to complement the results of the spray bar test and not used exclusively as a means of evaluation.

REFERENCES

- International Building Code, 2003 and 2006 editions. International Code Council, 2003, 2006.

- Water Repellents for Concrete Masonry Walls, TEK 19-01, Concrete Masonry & Hardscapes Association, 2006.

- Design for Dry Single-Wythe Concrete Masonry Walls, TEK 19-02B, Concrete Masonry & Hardscapes Association, 2012.

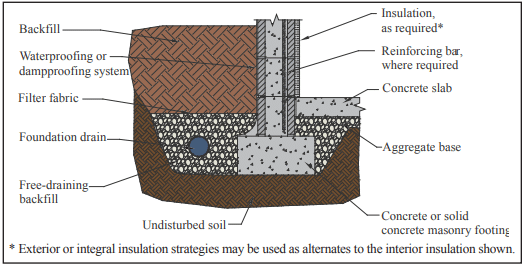

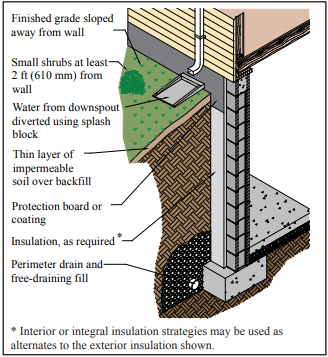

- Preventing Water Penetration in Below-Grade CM Walls, TEK 19-03B, Concrete Masonry & Hardscapes Association, 2012.

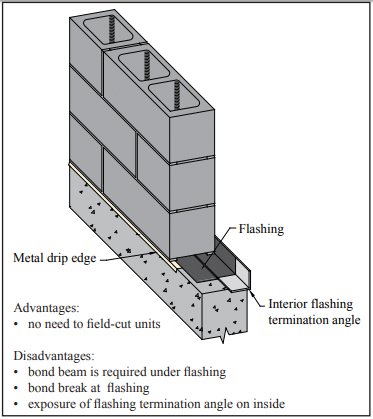

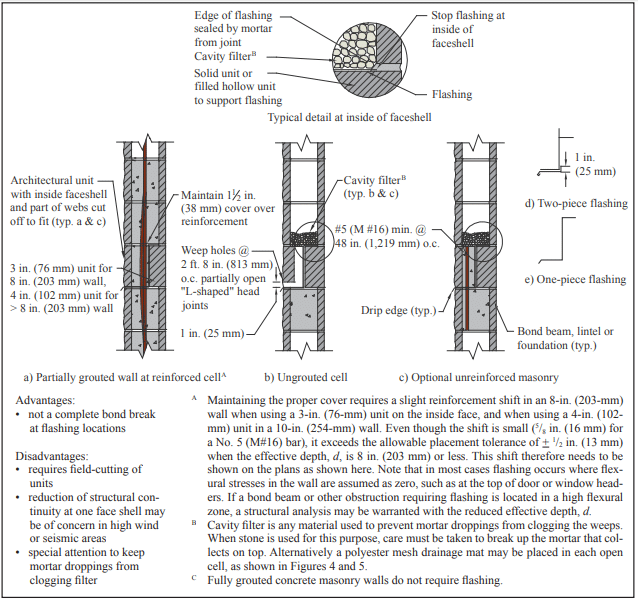

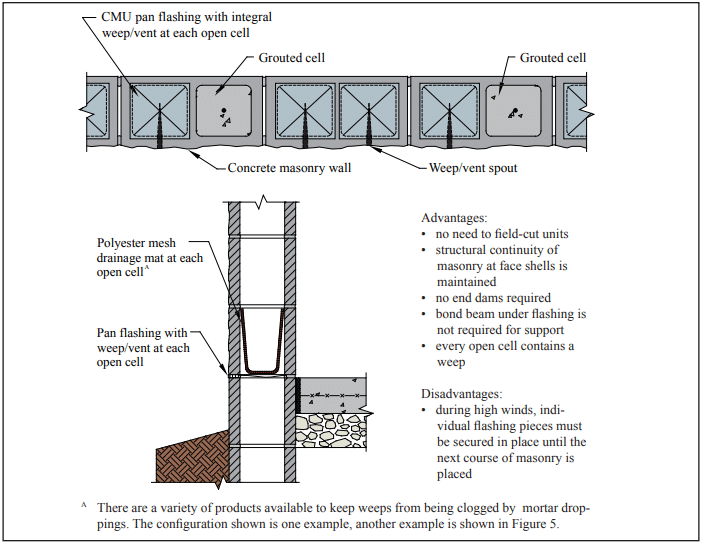

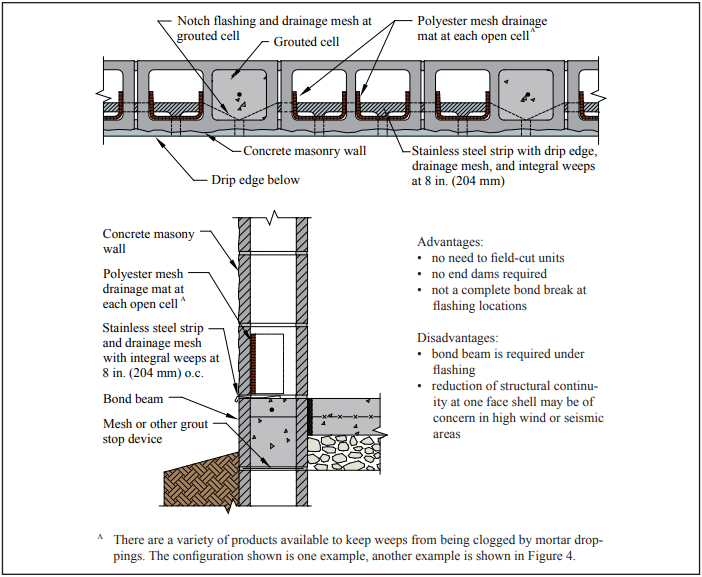

- Flashing Strategies for Concrete Masonry Walls, TEK 19-04A, Concrete Masonry & Hardscapes Association, 2008.

- Flashing Details for Concrete Masonry Walls, TEK 19-05A, Concrete Masonry & Hardscapes Association, 2008.

- Crack Control Strategies for Concrete Masonry Construction, CMU-TEC-009-23, Concrete Masonry & Hardscapes Association, 2023.

- Water Droplet Test Method for Concrete Masonry Units, CMHA Method CMU-WR1-07, Concrete Masonry & Hardscapes Association, 2007.

- Spray Bar Test Method for Concrete Masonry Units, CMHA Method CMU-WR2-07, Concrete Masonry & Hardscapes Association, 2007.

- Water Uptake Test Method for Concrete Masonry Units, CMHA Method CMU-WR3-07, Concrete Masonry & Hardscapes Association, 2007.

- Standard Specification for Loadbearing Concrete Masonry Units, ASTM C 90-06. ASTM International, 2006.

- Standard Specification for Concrete Facing Brick, ASTM C 1634-06. ASTM International, 2006.

NCMA and the companies disseminating this technical information disclaim any and all responsibility and liability for the accuracy and the application of the information contained in this publication.