Masonry Mortar Testing

INTRODUCTION

Masonry mortars are composed of cementitious materials, aggregates, water, and admixtures when specified. Cementitious materials include portland cement, masonry cement, mortar cement, slag cement, blended hydraulic cement, hydraulic cement, quicklime, hydrated lime and lime putty. Aggregates consist of natural sand or manufactured sand. Admixtures may include such materials as coloring pigments, water repellent agents, accelerators, retarders and air-entraining agents. These materials are described in Mortars for Concrete Masonry, TEK 09-01A (ref. 1).

Quality assurance testing of site-prepared mortar is fairly uncommon, except on large jobs or for essential facilities. When mortar testing is required, it is essential that all parties involved possess a thorough knowledge of the mortar specifications, test methods and standard industry practices. Misinterpretations of these standards can result in improper testing and confusion regarding compliance with specifications.

Typically, project specifications require mortar to comply with Standard Specification for Mortar for Unit Masonry, ASTM C270 (ref. 2). Two methods of demonstrating compliance with ASTM C270 are permitted: the proportion specification or the property specification. Note that these compliance options are completely independent of each other; the requirements from one should not be used in conjunction with the other. Of the two options, the proportion specification is much more commonly used. TEK 09-01A covers the proportion specification in detail.

Although physical testing of the mortar is not required to demonstrate compliance with the proportion specification, the mortar is often tested to verify consistency throughout the job, most often by cone penetration or compressive strength testing. The property specification requires testing to be performed on laboratory-prepared mortar to demonstrate compliance with a specified minimum compressive strength, minimum water retention and maximum air content. This information is required for submittals, so is performed prior to construction. Where special inspection is required in accordance with the International Building Code (ref. 3), the special inspector, as part of his duties, is required to verify compliance with the approved mix proportions for field-prepared mortar. Both consistency testing and testing to verify compliance with the property specification are covered in this TEK.

Field-prepared and preconstruction mortar should be evaluated using Standard Test Method for Preconstruction and Construction Evaluation of Mortars for Plain and Reinforced Unit Masonry, ASTM C780 (ref. 4), which includes the following test methods: consistency by cone penetration; consistency retention by cone penetration; consistency by modified concrete penetrometer; mortar-aggregate ratio and water content; air content; and compressive strength. Note that mortar compressive strength is not an accurate indication of mortar strength in the wall, nor of the masonry wall compressive strength. This is discussed in detail in the section Compressive Strength Testing of Field-Prepared Mortar, below.

Note that the physical properties of these field mortar evaluations cannot be compared to the values required by the ASTM C270 property specification. In fact, ASTM does not publish minimum compressive strength requirements for field-prepared mortar.

When fresh mortar is placed on concrete masonry units during construction, its characteristics immediately begin to change due to water absorption by the masonry units. Nearly all of the available mortar test methods, however, are performed on mortar before it comes into contact with masonry units. Therefore, the properties of the sampled and tested mortar can be expected to differ significantly from mortar in contact with masonry units. Because conditions of the units and environment can vary greatly from job to job, the properties of the plastic mortar may need to vary as well to ensure quality construction. For this reason, no pass/fail criteria exist for field tests of mortar.

Standard Guide for Quality Assurance of Mortars, ASTM C1586 (ref. 5) provides guidance on the proper use of ASTM C270 and C780 for evaluating masonry mortar produced in the laboratory and at the construction site.

MORTAR CONSISTENCY

The most important aspect of mortar quality control is consistency throughout the construction project. The test methods outlined in ASTM C780 are intended to evaluate that consistency. Test results acquired throughout construction are compared to a baseline preconstruction evaluation.

The cone penetration test offers a quantitative measure of mortar consistency. Test values indicate the mortar workability, which may be affected by water content, aggregate properties, batch properties and other factors. Tested values are likely to change throughout a project’s duration due to variable site conditions as well as variations in masonry unit moisture content and absorption characteristics.

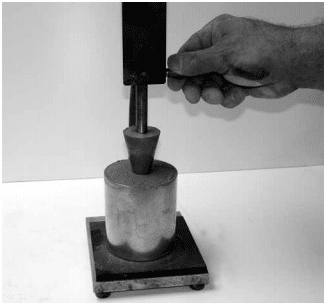

Cone penetration tests are performed by dropping a conical plunger from a specified height into a measured mortar sample and measuring the resulting depth of penetration, as shown in Figure 1.

MORTAR AGGREGATE RATIO

Mortar quality assurance often includes verification that mortar materials are proportioned as specified. ASTM C780 Annex A4 provides a method for sampling mortar from the field and determining the ratio of aggregate to cementitious material in the sample by weight. The mortar sample is passed through a No. 100 (150-µm) sieve to determine the percentage of material coarser than 150-µm. These results are compared to a sieve analysis of the aggregate used in the mortar to determine what fraction of the material passing the sieve is aggregate, and what fraction is cementitious material.

To complete the calculations in the test method, the mortar water content must also be determined, as detailed in Annex A4.

MORTAR COMPRESSIVE STRENGTH TESTING

One of the most universally recognized properties of masonry is compressive strength. While this property may not be the most important for masonry mortar, it is often perceived as such because compressive strength values are generally understood and are relatively easy to determine. Confusion and misinterpretation sometimes exist, however, when interpreting project specification requirements for mortar strength because there are several different compressive strength test methods included in ASTM Standards and model building codes. These methods were established to address specific needs, and they differ from each other in test requirements for obtaining, conditioning and testing mortar samples and specimens. Note that the mortar compressive strength determined in a laboratory is not indicative of either the strength of the mortar in the wall, nor of the masonry (i.e., wall) compressive strength. Specification for Masonry Structures (ref. 6) includes two alternatives for documenting masonry compressive strength; one based on the type of mortar and the compressive strength of the masonry units; the other based on compression testing of masonry prisms.

Compressive Strength Testing of Laboratory-Prepared mortar

Verifying compliance to the ASTM C270 property specification requires mortar compressive strength to be tested in accordance with Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or 50-mm Cube Specimens), ASTM C 109 (ref. 7), with modifications regarding specimen storage and conditioning.

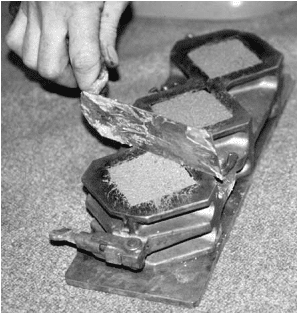

Compressive strength testing in accordance with ASTM C270 is conducted on specimens that are proportioned, mixed and conditioned in the testing laboratory. Water content of the mortar sample is such that the mortar flow must be 110 ± 5%. Compressive strength test specimens are 2 in. (51 mm) mortar cubes cast in nonabsorbent molds (see Figure 2) and cured in a moist room or moist cabinet meeting the requirements of ASTM C511, Standard Specification for Mixing Rooms, Moist Cabinets, Moist Rooms and Water Storage Tanks Used in the Testing of Hydraulic Cements and Concretes (ref. 9), until tested.

ASTM test methods emphasize the importance of extreme care in observing the testing procedures used to verify C270 requirements. According to Note 8 of ASTM C109: “Reliable strength results depend upon careful observance of all the specified requirements and procedures. Erratic results at a given test period indicate that some of the requirements and procedures have not been carefully observed, for example, those covering the testing of the specimens as prescribed in 10.6.2 and 10.6.3. Improper centering of specimens resulting in oblique fractures or lateral movement of one of the heads of the testing machine during loading will cause lower strength results.”

To facilitate centering the test specimens, the compression testing machine is required to have a spherically-seated upper bearing block attached at the center of the upper head. The bearing surface diagonal or diameter is required to be only slightly greater than the diagonal or diameter of the specimen.

Compressive Strength Testing of Field-Prepared Mortar

Compressive strength is one of the most commonly tested properties of field mortar. The test, described in ASTM C780, provides an indication of mortar consistency during construction, not as an indication of the compressive strength of the masonry, or even of the mortar in the wall. Compressive strength test results should be compared on a periodic basis to evaluate uniformity. These test results can be compared to preconstruction test results of similarly prepared mortar to provide a reference to a preapproved laboratory-prepared mortar strength.

Knowledgeable interpretations of results are necessary. As an example, consider the mortar’s water to cement ratio, which can have a significant effect on the tested strength. Mortar on site is adjusted to accommodate field conditions: on a hot sunny day, the mason may desire a more plastic mortar with a higher water content. Mortar sampled on this day will have a lower tested compressive strength than a similar mortar sampled on a cooler, damper day, which would likely be mixed using less water. However, the end result—the condition of the mortar in the wall—may be very comparable. These factors must be accounted for when interpreting compressive strength test results of field-prepared mortar.

Note that the results of these evaluations are not representative of the strength of the mortar in the wall, rather, they represent approximate mortar strengths only. The tested compressive strength of field-mixed mortar may be significantly less than that of hardened mortar joints for several reasons.

- Mortar specimens are cast in nonabsorbent forms, whereas mortar in the wall is exposed to the suction from absorbent masonry units, reducing the water to cement ratio, which in turn increases the compressive strength.

- The aspect ratio of the test specimens is greater than that of mortar joints. The typical mortar joint, at ⅜ in. (9.5 mm) high with a depth of at least 1 in. (25 mm), results in a broad, stable configuration that is naturally able to carry more load than the comparatively taller and more slender mortar specimens used for material evaluation. When tested at an aspect ratio of ⅜:1, tested mortar compressive strength values are routinely 8,000 to 10,000 psi (55.16 to 68.95 MPa).

For these reasons as well as others, field mortar compressive strength test results should never be compared to the requirements in ASTM C270 Table 2, which apply to laboratory-prepared mortar only.

ASTM C780 permits the use of cube or cylinder molds. Cylinder molds of 2 or 3 in. (51 or 76 mm) diameter have heights twice their diameter. Due to the higher aspect ratio of cylinder specimens, tests on cylindrical specimens result in tested compressive strength values approximately 15% less than those of cube specimens of the same mortar. If cylinder test results are to be directly compared to those for cubes, correction factors should be applied to the cylinder specimen results.

Immediately after sampling the mortar, it is placed in the molds, consolidated and covered to prevent evaporation per the procedures dictated by C780. The filled molds are stored for 24 hours in conditions as close to laboratory conditions as possible, at which point they are transported to the laboratory and stored in a moist room for another 24 hours. The specimens are then stripped of their molds and stored in the moist room or closet until 2 hours prior to compressive strength testing.

Prior to testing, mortar cylinders are capped with a gypsum or sulfur capping compound to provide uniform parallel bearing surfaces. Mortar cubes, however, are tested without caps, as the molded cube surfaces provide a smooth and uniform bearing surface. The specimens are tested in a moist condition. The axis of the specimen is aligned with the center of thrust of the spherically-seated (upper) bearing block of the compression machine. Load is applied to the specimen continuously and without shock until failure, and the compressive strength, type of failure, and appearance of the mortar is reported.

Uniform Building Code Standard 21-16, Field Test Specimens For Mortar (ref. 10), contained another method to obtain mortar compressive strength test specimens. This method prescribes ½ to ⅝ in. (13 to 16 mm) thickness of mortar to be spread on a masonry unit and allowed to stand for one minute. The mortar is then removed from the unit and placed in a cube or cylinder for compressive strength testing. The test method, however, is no longer used or referenced in current codes and standards and would not provide results that can be compared to C270 properties.

WATER RETENTION

The property specification of ASTM C270 requires a minimum water retention of 75% when tested in accordance with Standard Test Method for Water Retention of Hydraulic Cement-Based Mortars and Plasters, ASTM C1506 (ref. 15). This test was developed to measure the ability of a mortar to retain its mix water under the suction of the adjacent masonry unit. A certain amount of water absorption by the unit is beneficial, but too much may be detrimental.

Water retention is determined in the laboratory by measuring the mortar’s “initial flow,” and “flow after suction.” Initial flow is the percent increase in diameter of a mortar sample when it is placed on a flow table and dropped 25 times in 15 seconds. The same procedure is used to determine flow after some of the mortar’s mix water has been removed by an applied vacuum, which is meant to simulate the suction of masonry units on mortar. Water retention is the ratio of flow after suction to initial flow, expressed as a percentage.

AIR CONTENT

The ASTM C270 property specification includes a limit on the mortar air content. In general, greater air contents result in greater mortar durability and workability, but reduced mortar bond strength.

Air content is determined in accordance with ASTM C91, with the exception that the laboratory-prepared mortar is required to be of the materials and proportions used in the construction. The air content of the mortar is determined by calculation using the weight of a sample of mortar and accounting for all of the materials used. The calculation requires precise measurements of all materials and a knowledge of the specific gravity of those materials.

ASTM C780 also includes procedures for determining mortar air content using a pressure or volumetric method, either of which can be used in repetitive tests to evaluate the effects of changes in mixing time, mixing procedures, or other variables.

FLEXURAL BOND STRENGTH

ASTM C1329 Standard Specification for Mortar Cement (ref. 11) covers additional requirements for masonry mortars using mortar cement as a cementitious material. Although mortar cement is similar to masonry cement, it must achieve a minimum bond strength and must meet a lower air content than masonry cement. Mortar cement is permitted to be used in buildings assigned to Seismic Design Categories D, E or F, whereas masonry cement and Type N mortar cannot be used as part of the lateral force-resisting system for these buildings (ref. 12). Compliance testing for flexural bond strength is conducted in accordance with ASTM C1072 Standard Test Method for Measurement of Masonry Flexural Bond Strength (ref. 13). This method relies in turn on Standard Test Methods for Evaluating Masonry Bond Strength, ASTM C1357 (ref. 14). C1357 uses a prism constructed of “standard masonry units,” defined for this use as solid 3⅝ x 2¼ x 7⅝ in. (92 x 57 x 194 mm) units. Mortar bond is determined by calculating the modulus of rupture based on wrenching units from the prism using a bond wrench testing apparatus. C1072 includes detailed requirements for aggregates, mix design, manufacturing, size, curing and moisture content of the “standard” concrete masonry units used to determine compliance.

REFERENCES

- Mortars for Concrete Masonry, TEK 09-01A. Concrete Masonry & Hardscapes Association, 2004.

- Standard Specification for Mortar for Unit Masonry, ASTM C270-14. ASTM International, Inc., 2014.

- International Building Code. International Code Council, 2012.

- Standard Test Method for Preconstruction and Construction Evaluation of Mortars for Plain and Reinforced Unit Masonry, ASTM C780-14. ASTM International, Inc., 2014.

- Standard Guide for Quality Assurance of Mortars, ASTM C1586-05(2011). ASTM International, Inc., 2011.

- Specification for Masonry Structures, TMS 602-13/ACI 530.1-13/ASCE 6-13. Reported by the Masonry Standards Joint Committee, 2013.

- Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or 50-mm Cube Specimens), ASTM C109/C109M-13. ASTM International, Inc., 2013.

- Standard Specification for Masonry Cement, ASTM C91/C91M-12. ASTM International, Inc., 2012.

- Standard Specification for Mixing Rooms, Moist Cabinets, Moist Rooms and Water Storage Tanks Used in the Testing of Hydraulic Cements and Concretes, ASTM C511-13. ASTM International, Inc., 2013.

- Field Test Specimens for Mortar, UBC Standard 21-16, International Conference of Building Officials, 1994.

- Standard Specification for Mortar Cement, ASTM C1329/C1329M-12. ASTM International, Inc., 2012.

- Building Code Requirements for Masonry Structures, TMS 402-13/ACI 530-13/ASCE 5-13. Reported by the Masonry Standards Joint Committee, 2013.

- Standard Test Method for Measurement of Masonry Flexural Bond Strength, ASTM C1072-13e1. ASTM International, Inc., 2013.

- Standard Test Methods for Evaluating Masonry Bond Strength, ASTM C1357-09. ASTM International, Inc., 2009.

- Standard Test Method for Water Retention of Hydraulic Cement-Based Mortars and Plasters, ASTM C1506-09. ASTM International, Inc., 2009.