Articulating Concrete Block (ACB) Installation

INTRODUCTION

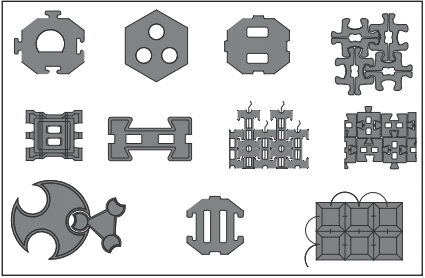

Articulating concrete block (ACB) revetment systems are used to provide erosion protection. The ACB system is a matrix of individual concrete blocks placed together to form an erosion-resistant revetment with or without a geotextile underlay for subsoil retention. General information on ACB systems can be found in ACB-TEC-001-14 Articulated Concrete Block for Erosion Control (ref. 1).

Proper installation of an ACB revetment system is essential to achieve suitable hydraulic performance and maintain stability against the erosive force of flowing water during the design hydrologic event. Quality workmanship is important throughout the installation, including subgrade preparation, geotextile placement, block system placement, backfilling and finishing, and inspection.

These guidelines apply to the installation of ACB revetment systems, whether hand-placed or placed as a mattress. They are based on Design Manual for Articulating Concrete Block (ACB) Revetment Systems (ref. 2) and comply with ASTM D6884, Standard of Practice for the Installation of Articulating Concrete Block (ACB) Revetment Systems (ref. 3). These guidelines do not purport to address the safety issues associated with installation of ACB revetment systems, including use of hazardous materials, mechanical equipment, and operations. It is the responsibility of the contractor to establish and adopt appropriate safety and health practices, and comply with prevalent regulatory codes, such as OSHA (Occupational Health and Safety Administration) regulations.

SOIL SAMPLES

When rough grading is complete, soil samples representative of the subgrade conditions should be obtained in accordance with the contract documents/project specifi cations or at a minimum frequency of one sample per 50,000 blocks, or additional fraction thereof, and tested for:

- particle size distribution (ASTM D422, ref. 4)

- Atterberg limits (ASTM D4318, ref. 5)

- Standard Proctor density (ASTM D698, ref. 6)

The system includes a geotextile underlay compatible with the subsoil that allows hydraulic infiltration and exfiltration to occur while providing particle retention. Granular filters may be used in place of, or in combination with, the geotextile per the engineer’s design drawings and specifications. When a granular filter is used, its gradation must meet the design gradation stated in the contract documents/project specification and should be tested for grain size distribution at the same frequency as the subgrade soil testing. Prior to placing the geotextile and ACB revetment system, laboratory test results must be submitted to the engineer to ensure conformance with design parameters.

SUBGRADE PREPARATION

Stable and compacted subgrade soil should be prepared to the lines, grades and cross sections shown on the contract drawings. Termination trenches and transitions between slopes and embankment crests, benches, berms, and toes should be compacted, shaped and uniformly graded to facilitate intimate contact between the ACB revetment system and the underlying grade. Secure the revetment in a manner that prevents soil migration when the ACB matrix is terminated at a structure, such as a concrete slab or wall.

Subgrade soil should be approved by the engineer to confirm that it meets the required material and compaction standards. Soils not meeting the required standards should be removed and replaced with approved material, as specified by the project specification or the engineer.

Care should be taken not to excavate below the grades shown on the contract drawings, unless directed by the engineer. Subgrade excavation above the water line should not be more than 2 in. (51 mm) below the grade indicated on the contract drawings. Subgrade excavation below the water line should not be more than 4 in. (102 mm) below the grade indicated on the contract drawings.

Where such areas are below the allowable grades, they should be brought to grade by placing approved material and compacting in lifts not exceeding 6 in. (152 mm) in thickness. Where it is impractical, in the opinion of the engineer, to dewater the area to be filled, over-excavations should be backfilled with crushed rock or stone conforming to the grading and quality requirements of well-graded coarse aggregate in ASTM C33, Standard Specification for Concrete Aggregates (ref. 7), or as directed by the engineer.

Where such areas are above the allowable grades, they should be brought to grade by removing material, or reworking existing material, and compacting as directed by the engineer.

When preparing dry areas to receive the ACB system, the surface should be graded smooth to ensure intimate contact between the subgrade surface and the geotextile and between the geotextile and the bottom surface of the ACB revetment system. Unsatisfactory soils, soils too wet to achieve desired compaction, and soils containing roots, sod, brush or other organic materials, should be removed, replaced with approved material and compacted. The subgrade should be uniformly compacted to a minimum 90 percent of the Standard Proctor density (ASTM D698) or as required by the project specification, whichever is more stringent. Should the subgrade surface for any reason become rough, eroded, corrugated, uneven, textured or traffic marked prior to ACB installation, such unsatisfactory portion should be scarified, reworked, recompacted or replaced as directed by the engineer.

The subgrade should be raked, screeded or rolled by hand or machine to achieve a smooth compacted surface that is free of loose material, clods, rocks, roots or other materials that would prevent satisfactory contact between the geotextile and the subgrade.

Immediately prior to placing the geotextile and ACB system, the prepared subgrade should be inspected and approved by the engineer.

GEOTEXTILE PLACEMENT

The geotextile should be placed directly on the prepared subgrade, in intimate contact with the subgrade and free from folds or wrinkles. The geotextile must be placed such that placement of the overlying materials will not excessively stretch or tear the geotextile.

The geotextile should be placed so that the upstream strips of fabric overlap downstream strips, and so that upslope strips overlap down-slope strips. Overlaps should be in the direction of flow wherever possible. Geotextile joints should be overlapped a minimum of 3 ft (1 m) for below-water installations and a minimum 1 ½ ft (0.5 m) for dry installations in accordance with ASTM D6884 (ref. 3). When a sewn seam is used for seaming of woven geotextile, the thread should be high-strength, UV-resistant polypropylene or polyester.

When a granular filter is used, the geotextile should be placed to encapsulate the granular filter as shown in Figure 1. The distance between encapsulation points should not exceed 20 ft (6 m). The geotextile should extend to the edge of the revetment within the top, toe and side termination points of the revetment. If necessary to expedite construction and to maintain the recommended overlaps, anchoring pins or 11 gauge, 6- by 1-in. (152 by 25 mm) U-staples may be used; however, weights (e.g., sand-fi lled bags) are preferred to prevent creating holes in the geotextile.

After geotextile placement, the work area should not be disturbed so the intimate contact between the geotextile and the subgrade is maintained. The geotextile should not be left exposed longer than the manufacturer’s recommendation, to minimize damage due to ultraviolet radiation.

ACB SYSTEM PLACEMENT

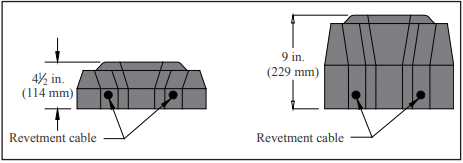

The articulating concrete block system should be placed on the geotextile in such a manner as to produce a smooth plane surface in intimate contact with the geotextile. For blocks within the mat and blocks that are hand set, the joint spacing between adjacent blocks must be maintained to prevent binding of blocks and to achieve block-to-block interlock.

In curvature and grade change areas, alignment of the individual block and the orientation of the adjacent block must provide for intimate block-to-fabric contact and block-to-block interlock. Care should be taken during block installation to avoid damage to the geotextile or subgrade. When a geotextile is used, the ACB system placement should preferably begin at the upstream end and proceed downstream to minimize undermining of the revetment system if flows occur before installation is complete. If the ACB system is to be installed from downstream up, a contractor option is to place a temporary toe on the front edge of the ACB system to protect against undermining when flows are anticipated.

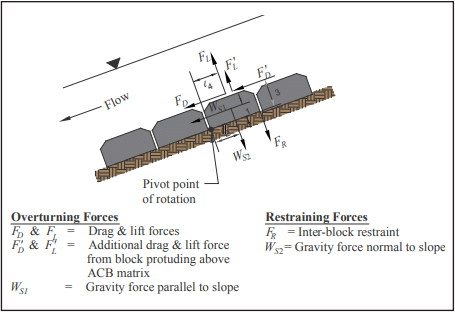

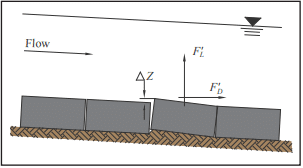

On sloped sections, when practical, placement should begin at the toe of the slope and proceed up the slope. Block placement should not bring block-to-block interconnections into tension. Individual blocks within the plane of the finished system must not exceed the protrusion tolerance used in the stability design of the system. The typical protrusion tolerance is ½ in. (13 mm).

If assembled and placed as large mattresses, the articulating mats can be attached to a spreader bar to aid in lifting and placing the mats into their proper positions using a crane. The mats should be placed side-by-side and/or end-to-end so the mats abut each other. Mat seams or openings between mats greater than 2 in. (51 mm) between blocks should be filled with grout.

Whether ACBs are placed by hand or in large mattresses, distinct grade changes should be accommodated with a well-rounded transition (i.e., minimum radius determined by individual system characteristics). Figure 2 shows a conceptual detail of a minimum radius for a top and toe-of-slope transition for bed and bank protection, while Figure 3 shows a top-of-slope transition and a typical toe detail for bank protection. Conceptual details for additional conditions are illustrated in Design Manual for Articulating Concrete Block (ACB) Revetment Systems (ref. 2).

If a discontinuous revetment surface exists in the direction of flow, a grout seam at the grade change location should be provided to produce a continuous, flush-finished surface. Grout seams should not be wider than one-half the maximum dimension of a single block.

Termination trenches should be backfilled with approved fill material and compacted flush with the top of the blocks. The integrity of a soil trench backfill must be maintained to ensure a surface that is flush with the top surface of the ACBs throughout the entire service life. Top, toe and side termination trenches should be backfilled with suitable fill material and compacted immediately after the block system has been placed.

Anchors or other penetrations through the geotextile should be grouted or otherwise repaired in a permanent fashion to prevent migration of subsoil through the penetration point.

Do not use the ACB revetment system as a road for heavy construction traffic unless it is designed as a flexible pavement that can handle the expected wheel loads. Light traffic, such as single axle trucks and mowing equipment, may operate on installed ACB systems.

FINISHING

The open area of the articulating concrete block system is typically either backfilled with suitable soil for revegetation or with ⅜– to ¾-in. (9.5 to 19 mm) diameter uniform crushed stone, or a mixture thereof. Crushed stone can enhance the interlock restraint, but can make the ACB revetment system less flexible. Backfilling with soil or granular fill within the cells of the system should be completed as soon as possible after the revetment has been installed. When topsoil is used as a fill material above the normal waterline, overfilling by 1 to 2 in. (25 to 51 mm) may be desirable to allow for consolidation.

INSPECTION

Each step of installation—subgrade preparation, geotextile and granular filter placement, ACB revetment placement, and the overall finished condition, including termination points, should be inspected and approved by the engineer.

REFERENCES

- Articulated Concrete Block for Erosion Control, ACB-TEC-001-14, Concrete Masonry & Hardscapes Association, 2014.

- Design Manual for Articulating Concrete Block (ACB) Revetment Systems, ACB-MAN-001-20, Concrete Masonry & Hardscapes Association, 2020.

- Standard Practice for Installation of Articulating Concrete Block (ACB) Revetment Systems, ASTM D6884-03. ASTM International, Inc., 2003.

- Standard Test Method for Particle-Size Analysis of Soils, ASTM D422-63(2002). ASTM International, Inc., 2002.

- Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils, ASTM D4318-05. ASTM International, Inc., 2005.

- Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12,400 ft-lbf/ft³ (600 kN-m/m³), ASTM D698-00ae1. ASTM International, Inc., 2001.

- Standard Specification for Concrete Aggregates, ASTM C33-03. ASTM International, Inc., 2003.