Seismic Design of Segmental Retaining Walls

INTRODUCTION

This TECH describes a method of analysis and design for conventional and geosynthetic-reinforced segmental retaining walls (SRWs) under seismic loading. The methodology extends the approach for structures under static loading to simple structures that may be required to resist additional dynamic loads due to earthquakes. The seismic design method described briefly in this Tech Note, and in detail in the CMHA Design Manual for Segmental Retaining Walls and SRWallv4 design software (refs. 1, 2), adopts a pseudo-static approach and uses the Mononobe-Okabe (M-O) method to calculate dynamic earth forces. The methodology adopts many of the recommendations contained in AASHTO/FHWA (refs. 3, 4) guidelines for the design and analysis of mechanically stabilized earth (MSE) structures subjected to earthquake loads. However, the CMHA Design Manual for Segmental Retaining Walls goes beyond the AASHTO/FHWA publications by addressing the unique stability requirements of SRWs that are constructed with a dry-stacked column of modular block units.

Properly designed reinforced SRWs subjected to seismic and/or dynamic loading will in general perform well due to their flexible nature and enhanced ductility. When an SRW requires seismic analysis, that evaluation should be performed in addition to the static analysis to satisfy all static and seismic safety factors, as outlined in the Design Manual for Segmental Retaining Walls. The project’s geotechnical engineer should select the ground acceleration design parameters considering the local experience, state of practice and site conditions. CMHA’s methodology uses a displacement approach that explicitly incorporates wall movement in the stability analysis, assuming small outward displacements are allowed, and reduces the Peak Ground Acceleration (PGA) following FHWA’s approach. It should be noted that outward displacements caused by “near” maximum probable magnitude earthquakes may bring SRWs outside of tolerable batter deviations, thereby requiring mitigation. As with any other structure, the intent of the seismic design is to prevent catastrophic failure (a failure leading to risk to life, limb, or property), and needs to be evaluated after a near design event.

For satisfactory performance in the field, the designer should specify the best construction and inspection practices, adequately addressing items such as materials, installation, compaction, and internal and external drainage (i.e., drain tiles, chimney drains, swales, etc.). For more details refer to SRW-TEC-005-09, Guide to Segmental Retaining Walls (ref. 5), SRW-TEC-008-12, Inspection Guide for Segmental Retaining Walls (ref. 6), and the CMHA Design Manual for Segmental Retaining Walls.

DESIGN ASSUMPTIONS

The CMHA seismic design and analysis methodology applies when the following conditions are met:

- SRW structures are free-standing and able to displace horizontally at the base and yield laterally through the height of the wall. This assumption is based on installation recommendations of a system that is placed on soils and a flexible leveling pad of well-compacted gravel or unreinforced weak concrete that can crack if necessary.

- Reinforced and retained soils are cohesionless, unsaturated, and homogeneous. Soil strength is described by the Mohr-Coulomb failure criterion. The apparent cohesive strength component reported under Mohr-Coulomb failure criterion is ignored for conservatism. Adequate drainage details should also accompany the design to ensure the soils remain unsaturated and that the assumed design conditions are reached and maintained.

- Vertical ground acceleration is zero (kv = 0). Vertical ground acceleration is ignored based on the presumption that horizontal and vertical accelerations associated with a seismic event do not coincide.

- Geometry is limited to infinite or broken-backslope, and constant horizontal foreslope angle.

- Live surcharges are ignored at the top of the soil surface behind the facing column given their transient nature.

- Retained and reinforced soils are placed to a depth corresponding to the full height of the SRW facing units (i.e. wall design height, H).

- Cap units are ignored in the stability analysis and assumed to be securely attached such that they cannot be dislodged during ground shaking.

- The stabilizing influence of the wall embedment is ignored with the exception of bearing capacity analyses.

- No permanent surcharge or footing load exists within the active failure wedge.

- Global stability involving failure of soil volumes beyond the base of the SRW unit column and/or geosynthetic reinforced fill zone is not considered.

- SRW structures are built on competent foundations for which excessive settlement, squeezing or liquefaction are not potential sources of instability.

If there are more complex conditions, or for cases where M-O formulation leads to unrealistic results, it is recommended that numerical procedures using the same principles of M-O formulation be used. These include the well-known graphical Culmann method, Coulomb’s trial wedge method, or limit equilibrium slope stability programs that are outside of the scope of the CMHA Design Manual.

A limitation of the pseudo-static seismic design method presented here is that it can only provide an estimate of the margins of safety against SRW collapse or component failure, and does not provide any direct estimate of anticipated wall deformations. This is a limitation common to all limit-equilibrium design methods in geotechnical engineering.

GEOSYNTHETIC REINFORCED SEGMENTAL RETAINING WALLS— MODES OF FAILURE

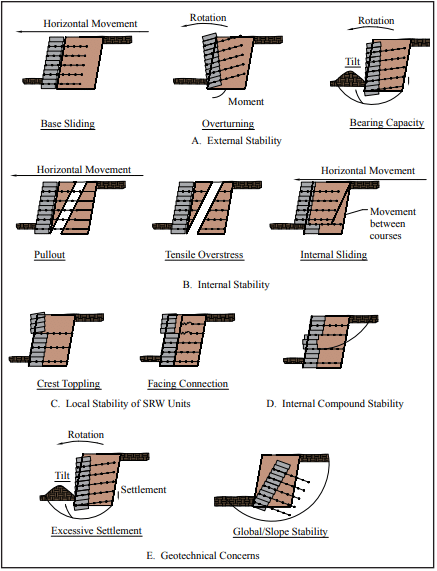

Stability analyses for geosynthetic reinforced SRW systems under static and seismic loading conditions involve separate calculations to establish factors of safety against external, internal, facing and internal compound modes of failure (Figure 1).

External stability calculations consider the reinforced soil zone and the facing column as a monolithic gravity structure. The evaluation of factors of safety against base sliding, overturning about the toe, and foundation bearing capacity is similar to that used for conventional reinforced concrete masonry gravity structures.

Internal stability analyses for geosynthetic reinforced soil walls are carried out to ensure that the structural integrity of the reinforced zone is preserved with respect to reinforcement over-stressing within the reinforced zone, pullout of geosynthetic reinforcement layers from the anchorage zone, and internal sliding along a reinforcement layer.

Facing stability analyses are carried out to ensure that the facing column is stable at all elevations and connections between the facing units and reinforcement layers are not over-stressed.

Internal compound stability analyzes the coherence of the block-geogrid system through potential compound slip circles that originate behind the soil-reinforced SRW and exit at the face of the wall.

Minimum recommended factors of safety (FS) of static and seismic design of geosynthetic reinforced SRW structures are given in Table 1. In general, FS for seismic design are taken as 75% of the values recommended for statically loaded structures following AASHTO/FHWA practice.

Potential concerns such as settlement of reinforced SRW structures due to compression, liquefaction, or squeezing of foundation soils is not considered here. Separate calculations for foundation-induced deformations may be required by the designer. In addition, slope instability involving volumes of soil beyond and below the base of the facing column is not considered. For global stability analysis, computer programs are available that consider the effects of both the stabilizing influence of reinforcement layers and destabilizing influence of seismic-induced ground acceleration (ref. 7).

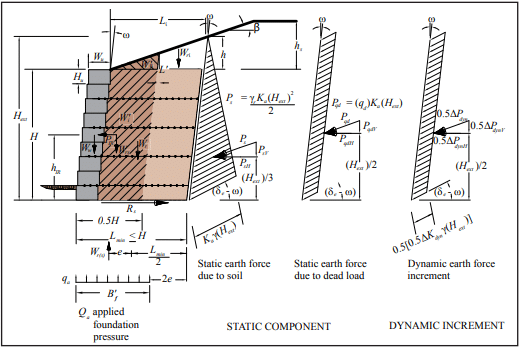

EXTERNAL STABILITY

External stability calculations are similar to those for conventional static conditions, with the addition of the inertial force due to wall weight and the dynamic earth increment. Dynamic earth pressure, shown in Figure 2, is used to calculate the destabilizing forces in otherwise conventional expressions for the factor of safety against sliding along the foundation surface, overturning about the toe, and bearing capacity failure of the foundations soils. By convention, only half of the dynamic earth force increment is applied when calculating external seismic forces on conventional and reinforced SRWs. The simplified geometry and forces shown in Figure 2 are used in external stability calculations.

INTERNAL STABILITY

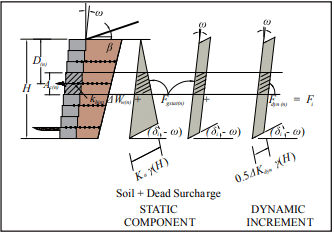

The contributory area approach (ref. 1, Sec. 7.5.2.2) used for the static stability analysis of SRWs is extended to the dynamic loading case (Figure 3). In this method, the reinforcement layers are modeled as tie-backs with the tensile force Fi in layer n equal to the earth pressure integrated over the contributory area Ac(n) at the back of the facing column plus the corresponding wall inertial force increment. Hence:

Fi(n) = khint ΔWw(n) + Fgsta(n) + Fdyn(n)

where:

khint ΔWw(n) = wall inertial force increment

Fgsta(n) = static component of reinforcement load

Fdyn(n) = dynamic component of reinforcement load.

Internal stability calculations are also similar to those carried out for conventional static conditions with the inclusion of dynamic earth pressure. For reinforced SRWs, full dynamic load is applied to internal stability with the exception of internal sliding that employs half ΔPdyn. Figure 3 shows the static and dynamic earth pressure distribution for internal stability calculations. The calculations for internal stability are presented in detail in Reference 1.

FACING STABILITY

Facing stability calculations are similar to those used for the static analysis with the addition of the dynamic load. To evaluate the connection strength, the connection capacity at each reinforcement elevation is compared to the tensile force Fi already determined. The crest toppling is evaluated, determining the static, inertial and dynamic forces acting on the unreinforced top blocks. Only half of the dynamic load ΔPdyn is used to mirror the external overturning analysis.

INTERNAL COMPOUND STABILITY

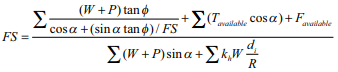

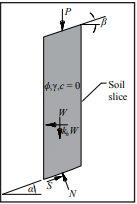

The consideration of seismic load for internal compound stability calculations is based on the addition of an inertial force (khW) associated with the mass of each soil slice (see Figure 4).

The incorporation of an additional dynamic load or inertial force is calculated as follows:

where:

di = vertical distance from the gravity center of the soil mass to the center of the slip surface

R = radius of the slip surface

Tavailable = available reinforcement force at the location of the intersection of the failure plane

Favailable = available facing force at failure plane exit.

FIELD PERFORMANCE

SRW performance during earthquakes is generally considered to be excellent (refs. 8, 9). Observations of SRWs within 31 miles (50 km) of the epicenter of both the Loma Prieta and Northridge earthquakes have shown that this type of retaining wall system can withstand considerable horizontal and vertical accelerations without experiencing unacceptable deformations. Similar to other structures subject to “near” maximum probable magnitude earthquakes, the designer should be aware that SRWs may need to be evaluated if damages are noticed, and repaired if necessary.

The design procedures presented in Design Manual for Segmental Retaining Walls, 3rd ed., provide a rational, detailed design methodology which, if followed, will allow designers to take advantage of SRW technology to build safe and economical retaining walls to withstand seismic forces.

REFERENCES

- Design Manual for Segmental Retaining Walls (Third Edition), Concrete Masonry & Hardscapes Association,

- SRWallv4, Concrete Masonry & Hardscapes Association

- Mechanically Stabilized Earth Walls and Reinforced Soil Slopes Design and Construction Guidelines, Elias, V., Christopher, B.R., and Berg, R.R., FHWA NHI-00-043,

- Standard Specifications for Highway Bridges, 17th AASHTO, 2002.

- Guide to Segmental Retaining Walls, SRW-TEC-005-09, Concrete Masonry & Hardscapes Association, 2009.

- Inspection Guide for Segmental Retaining Walls, SRW-TEC-008-12, Concrete Masonry & Hardscapes Association, 2010.

- Duncan, J.M., Low, B.K., and Shaeffer, V.R., STABGM: A Computer Program for Slope Stability Analysis of Reinforced Embankments, Virginia Polytechnic Institute,

- Field Observations of Reinforced Soil Structures Under Seismic Loading, Collin, G., Chouery-Curtis, V.E., and Berg, R. R., Proceedings International Symposium on Earth Reinforcement Practice, Fukuoka, Japan, 1992.

- Retaining Walls Stand Up to the Northridge Earthquake, Sandri, D., Geotechnical Fabrics Report 12 (4), 1994.