Grout Quality Assurance

INTRODUCTION

Two field tests are commonly performed for conventional grout—the slump test and the compressive strength test. Information about types of grout, grout properties and grout admixtures can be found in Grout for Concrete Masonry, TEK 09-04A (ref. 1). Information on grout mixing and placement is contained in Grouting Concrete Masonry Walls, TEK 03-02A (ref. 2).

SAMPLING GROUT

Grout should be sampled by a qualified technician. A minimum bulk sample size of ½ ft³ (0.014 m3) is required for slump and compressive strength tests (ref. 3). Two or more grout portions are taken at regularly spaced intervals during grout discharge, and are then combined to form a bulk sample. No more than 15 minutes should elapse between obtaining the first and last portion. To help ensure the sample is representative, the portions should be taken from the middle of the batch; no samples should be taken from the first nor last 10% of the discharge.

If sampled in the field, the incremental samples are transported to the testing location, with care to protect them from sun, wind and other potential sources of evaporation and contamination. The portions are then combined and remixed to form the bulk sample. The slump test must be started within 5 minutes of obtaining the final portion. Preparation of compressive strength specimens must begin within 15 minutes of obtaining the final portion.

GROUT CONSISTENCY

The slump test gives an indication of the consistency, water to cement ratio and/or fluidity of the field grout batch. Standard Test Method for Slump of Hydraulic-Cement Concrete, ASTM C 143 (ref. 4), provides test procedures to test grout slump in either the laboratory or the field. The measured grout slump should be between 8 and 11 in. (203 and 279 mm) to facilitate complete filling of the grout space and proper performance (ref. 5). When a 12 ft-8-in. (3.9 m) grout lift height is used as permitted in the 2005 edition of Specification for Masonry Structures (ref. 5), grout slump must be maintained between 10 and 11 in. (254 and 279 mm). When the rate of water loss may be high, such as when temperatures are elevated and/or the concrete masonry units are highly absorptive, slumps in the upper part of the range (i.e., more fluid) may be desirable, although care should be taken that the grout does not segregate because the slump is too high. High-slump grouts are advantageous when grout spaces are small or highly congested. When water will be absorbed at a slower rate, such as with lower absorptive concrete masonry units, grouts in the lower slump range are good selections. If grout spaces are large, or the lifts are short, slumps in the lower part of the range also can work well.

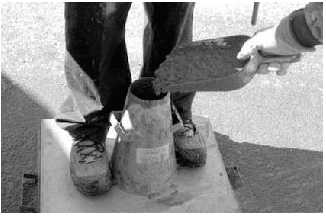

To perform the slump test, the cone, shown in Figures 1 and 2, is dampened and placed on a flat, rigid, nonabsorbent surface. The technician stands on the mold’s foot pieces to hold the mold firmly in place while filling the mold in three layers of equal volume (see Figure 1). The first layer should fill the mold to a depth of about 2 ⅝ in. (67 mm), the second to 6 ⅛ in. (156 mm) and the top layer should slightly overfill the mold. Each layer is rodded 25 times with a round steel tamping rod to consolidate the grout before the next layer is placed.

The middle and top layers are rodded through the depth of the layer, penetrating into the layer below. If the grout level falls below the top of the cone while rodding the top layer, grout is added to keep excess grout heaped above the top of the mold at all times. After the top layer is rodded, any excess grout is struck off flush with the top of the cone. Any grout which accumulates around the base of the mold is removed so that it does not interfere with the movement of the slumping grout.

Immediately after striking off and clearing grout from the base of the mold, the mold is lifted in 3 to 7 seconds by raising it vertically using a steady upward lift. The mold should not be twisted or moved sideways during lifting.

The slump is the vertical distance between the top of the cone and the displaced original center of the top surface of the specimen, as shown in Figure 2.

The entire test must be completed within 2 ½ minutes, from start of mold filling to measurement. If there is a decided falling away or shearing off of grout from one side or portion of the grout mass, the test should be disregarded and repeated with a fresh grout sample.

COMPRESSIVE STRENGTH TESTING

When grout compressive strength testing is required, the procedures of ASTM C 1019, Standard Test Method for Sampling and Testing Grout (ref. 3) are used. The Standard contains procedures for both field and laboratory grout compression testing and can be used either to help select grout proportions during preconstruction or as a quality control test for grout preparation uniformity during construction.

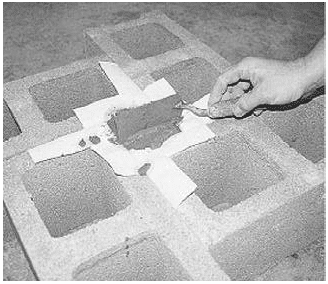

When used as part of a quality assurance program, the number of grout samples to be tested should be specified before the start of construction. One grout sample, as previously described, is used to make three compressive strength specimens. Grout specimens are formed in molds made from concrete masonry units with the same absorption and moisture content characteristics as those being used on the job (see Figures 3, 4).

Because the absorption characteristics of the grout mold must be similar to those experienced by the grout in the wall, when walls are constructed using both concrete and clay masonry units, the grout mold is constructed using both types of units, as shown in Figure 4.

The molds should be located where they can remain undisturbed for 24 to 48 hours, in a level area free from perceptible vibration.

Units for the mold are laid out to form a space with a square cross section, 3 in. (76 mm) or larger on each side, with a height twice its width. Nonabsorbent spacers are placed at the bottom of the square space if needed to achieve the required specimen height. Permeable liners, such as paper towels, are taped to the surrounding masonry units to break the bond between the grout specimen and the masonry units, but still allow water to be absorbed into the units.

Grout is poured into the mold in two lifts of approximately equal depth, with each layer rodded 15 times to eliminate any air bubbles, distributing the strokes uniformly over the cross section of the mold. When rodding the upper layer, the rod should penetrate about ½ in. (13 mm) into the bottom layer. After the upper layer is rodded, the top of the specimen is leveled with a straight edge as shown in Figure 5, such that there are no projections or depressions exceeding ⅛ in. (3.2 mm). The specimen is then immediately covered with damp fabric or similar material to promote curing.

Within 30 minutes of filling the mold, grout is added to completely fill any depression which may have formed due to initial water absorption. The top of the specimen is leveled again and re-covered to keep it damp until testing.

The specimens should remain undisturbed until the molds are removed, and should be protected from temperature extremes. After 24 to 48 hours, the molds are removed and the specimens are carefully packed for transport, keeping them damp, and shipped to the laboratory for testing.

Within 8 hours of removing the molds, laboratory personnel should store the specimens in a moist room, moist cabinet or water storage tank prior to testing.

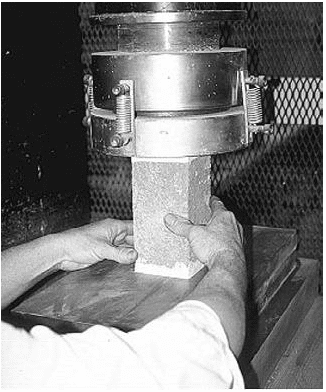

Specimen width, height and out-of-plumb are measured and recorded. Average widths are used to calculate the average cross-sectional area, which is used to determine compressive strength based on the maximum compressive load.

Prior to testing, the specimens should be capped in accordance with the applicable provisions of ASTM C 617, Standard Method of Capping Cylindrical Concrete Specimens, (ref. 6), and tested according to ASTM C 39, Standard Method of Test for Compressive Strength of Molded Concrete Cylinders (ref. 7) (see Figure 6). More detail on the test method and procedures are included in ASTM C 1019.

When approved, other methods of obtaining grout samples, such as drilling cores, may be used to test grout compressive strength. Because test results vary with the method of forming the specimen and with specimen geometry, these test results cannot be directly compared unless previous testing has established a relationship between the two methods of forming and specimen geometries.

Concrete test methods should not be used for grout as they do not simulate water absorption into masonry units. Grout cubes or cylinders formed in nonabsorptive molds will give unreliable results.

SELF-CONSOLIDATING GROUTS

Self-consolidating grout (SCG) is a highly fluid and stable grout mix that is easy to place and does not require consolidation or reconsolidation. SCG is similar in nature to conventional grout, although the mix design is significantly different: proportions of constituent materials are highly controlled and admixtures (typically in the form of superplasticizers with or without viscosity modifiers) are used to produce a plastic grout with desired properties. Controlled aggregate gradation is also important to maintain fluidity without segregation, to produce a mix that results in consistent properties throughout the grout lift.

Because of the fluid nature of the material, traditional measures of consistency and flow such as the slump cone test (ASTM C 143) are not applicable to SCG.

SCG is a relatively new material, which is not yet incorporated into building codes and standards. To date, compliance has been achieved in several cases by using the grout demonstration panel option in Specification for Masonry Structures (ref. 5). Quality assurance provisions are being developed. It is anticipated that SCG testing procedures will be similar to those for self-consolidating concrete, as the two materials are very similar.

REFERENCES

- Grout for Concrete Masonry, TEK 09-04A. Concrete Masonry & Hardscapes Association, 2005.

- Grouting Concrete Masonry Walls, TEK 03-02A. Concrete Masonry & Hardscapes Association, 2005.

- Standard Test Method for Sampling and Testing Grout, ASTM C 1019-03. ASTM International, 2003.

- Standard Test Method for Slump of Hydraulic-Cement Concrete, ASTM C 143/143M-03. ASTM International, 2003.

- Specification for Masonry Structures, ACI 530.1-05/ASCE 6-05/TMS 602-05. Reported by the Masonry Standards Joint Committee, 2005.

- Standard Practice for Capping Cylindrical Concrete Specimens, ASTM C 617-98(2003). ASTM International, 2003.

- Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens, ASTM C 39/C 39M-04a. ASTM International, 2004.

- Standard Practice for Sampling Freshly Mixed Concrete, ASTM C 172-04. ASTM International, 2004.