Do Manufactured Concrete Products Sequester CO2?

Revised 2024

Yes. From the moment a concrete masonry unit (CMU), segmental retaining wall (SRW) unit, concrete paver or slab, or other manufactured concrete product is formed, the material will begin to bind chemically to the carbon dioxide (CO2) in the environment. This sequestration, also referred to as carbonation or uptake of CO2 will continue indefinitely if there is a source of hydrated, hydraulic cement exposed to carbon dioxide. Because the very nature of concrete means the presence of hydrated cement, and because it is virtually impossible to prevent exposure to CO2, carbon sequestration is in essence a fundamental characteristic of concrete.

The fact that concrete masonry carbonates and sequesters CO2 has been well documented for decades [1]. Past research efforts, however, have focused simply on the fact that concrete masonry absorbs carbon dioxide, without defining how much, or how quickly, CO2 is absorbed. As the sustainable attributes and environmental impact of different construction materials becomes an increasingly important design objective, questions such as these continue to be raised. In the context of recognizing that CO2 is released during the manufacturing of portland related hydraulic cements, the evolution of this question then becomes how much CO2 is subsequently reabsorbed during the service life of the concrete product.

BASICS OF THE CARBON CYCLE OF CONCRETE

To answer this question, let’s go back to the beginning and look at the whole carbon cycle of concrete. First, portland cement is manufactured by combining limestone, clay and silica sand and heating them up in large rotary kilns to about 2700 °F (1500 °C). During this process CO2 is released to the atmosphere from the decomposition of the limestone and from the burning of the fuels needed to heat the kiln. Approximately 50% of the released CO2 comes from the decomposition of the limestone (which is referred to as calcination carbon emissions), 40% comes from the fuel combustion, and 10% comes from the other cement manufacturing plant processes. Overall, approximately 900 kg of CO2 is released per 1000 kg of portland cement produced. This is referred to as the embodied carbon or carbon footprint of the cement.

Next, concrete, including manufactured concrete products, is made up of a mixture of the portland cement combined with sand and stone. When these materials are mixed together with water, the cement hydrates during the curing process forming the ‘glue’ that holds the sand and stone together in the hardened concrete. While portland cement makes up only 7 to 20% of the total concrete mixture, it is the largest contributing factor to the embodied carbon in the final concrete and can contribute from 75 to over 90% of total embodied carbon of the concrete.

Finally, when the cement hydrates, it forms hydrated cement gel (which is the ‘glue’) and a byproduct called calcium hydroxide. From the moment concrete is produced and the cement begins to hydrate, it begins to reverse the calcination carbon emissions chemical reaction that originally released CO2 and starts to sequester CO2 from the atmosphere. Initially, this sequestered CO2 chemically combines with the calcium hydroxide byproduct to form calcium carbonate (also called limestone) which permanently locks the CO2 back into the matrix of the concrete. The sequestered CO2 also continues reacting with the cement gel to be permanently locked into the matrix as carbonated cement paste.

CARBONATION RATE – THE DIFFERENCE

BETWEEN DRY-CAST AND WET-CAST

CONCRETE

The speed at which the concrete sequesters CO2 is called the carbonation rate and is related to exposure conditions and the porosity of the concrete. The more open the structure of the concrete, the faster and further the CO2 can penetrate into the concrete to react with the calcium hydroxide and cement gel. This is where dry-cast manufactured products like CMU have a distinct advantage compared to regular wet-cast concrete. Because of the nature of the dry-cast manufacturing process, the CMU have interconnected voids throughout the concrete which allow carbon dioxide to easily penetrate into the dry-cast matrix. Coupled with the configuration of concrete masonry units (CMU), consisting of relatively thin face shells and webs, this results in signifi cantly higher natural carbonation rates of CMU compared to wet-cast concrete. By contrast, wet-cast concrete is more massive and does not have interconnected voids – the CO2 can only penetrate much more slowly through the small capillaries in the concrete matrix.

The carbonation rate of wet-cast concrete has been thoroughly studied and modeled. Reported carbonation rates of wetcast concrete vary from 1 to 5 mm (0.04 to 0.20 in.) per year depending on a multitude of factors, including the composition, curing, porosity, and permeability of the concrete, as well as the presence of moisture, and exposure conditions. Current models [2] indicate that 3000 psi wet-cast concrete under ideal exposure conditions would have carbonation uptakes of less than 2 kg/m3 of concrete at 28-days of age and approximately 8 kg/m3 after being exposed for 2 years. These are a small fraction of the total embodied carbon of the concrete – equivalent to less than 1% of the concrete’s total embodied carbon at 28-days of age and less than 3% after 2 years.

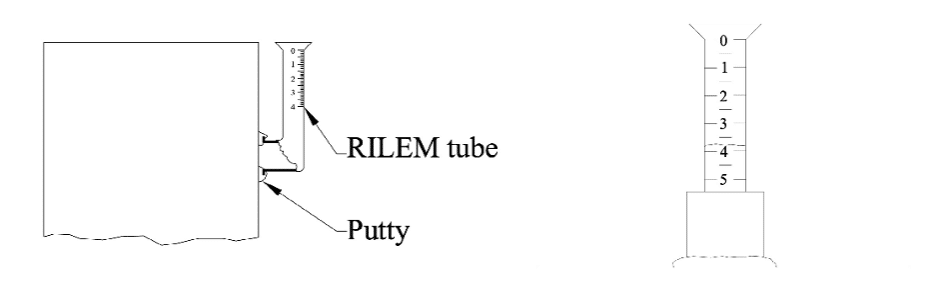

Until recently the carbonation rate of dry-cast concrete has not been systematically studied. In 2020, the NCMA Foundation undertook a study to measure the carbon sequestration rate of nine sets of CMU from across North America. The study culminated in a peer reviewed paper delivered at the ASTM Masonry Symposium [3]. The paper documented the results for the nine sets from ages of 28-days to 6-months and verified that CMU have a significantly higher rate of carbonation even in the manufacturing phase, or Cradle to Gate. CMHA has continued studying these nine sets and now has 2-year exposure data. The data show that on average the CMU had carbonation uptakes (or sequestered CO2 levels) of 19 kg/m3 of concrete at 28-days of age (considered to be the gate) and 42 kg/m3 after being exposed for 2 years. These represent 21% (at 28 days) and 49% (at 2 years) of the calcination carbon emissions originally

released from the limestone during the manufacturing of the cement. These are a significant fraction of the total embodied carbon of the concrete (which includes additional raw materials (like aggregates), CMU plant operations, and emissions from both the chemical reaction and for heating during cement production) – equivalent to about 8% of the concrete’s total embodied carbon at 28 days (gate) and approximately 18% after 2 years into the use phase of the building. Modeling of the current data indicates that these values may increase to 25% of the concrete’s total embodied carbon during the first 20 to 25 years of a building’s lifetime.

For the CMHA study, the CMU were stored outside in typical weather conditions for the Mid-Atlantic US, representative of (and applicable to) the wide range of exposure conditions and applications for CMU. Specific exposure conditions for a given application may impact sequestration results. CMHA is continuing to undertake more research to better understand and quantify CMU and other dry-cast concrete products ability to sequester CO2. While the current results are based on one wide-ranging study, the results reinforce CMUs reputation as one of the most sustainable and resilient building systems available.

REFERENCES

- CMU-TEC-009-23, Crack Control Strategies for Concrete Masonry Construction, Concrete Masonry & Hardscapes Association, 2023.

- MIT ‘s Whole Life Cycle Carbon Uptake Tool found on the MIT Concrete Sustainability Hub website, https://cshub.mit.edu/whole-life-cycle-carbon-uptake-tool/

- Conceptual Test Protocols for Measuring Carbon Sequestration of Manufactured Dry-Cast Concrete Products, C. Walloch, L. Powers, D. Broton, J. Thompson, in Masonry 2022: Advancing Masonry Technology, ed. B. Trimble, J. Farny (West Conshohocken, PA: ASTM International, 2022), 59–86, https://doi.org/10.1520/

STP164020210112.