Concrete Masonry Veneers

INTRODUCTION

In addition to its structural use or as the exterior wythe of composite and noncomposite walls, concrete brick and architectural facing units are also used as veneer over various backing surfaces. The variety of surface textures, colors, and patterns available makes concrete masonry a versatile and popular exterior facing material. Architectural units such as split-face, scored, fluted, ground face, and slump are available in a variety of colors and sizes to complement virtually any architectural style.

VENEER—DESIGN CONSIDERATIONS

Veneer is a nonstructural facing of brick, stone, concrete masonry or other masonry material securely attached to a wall or backing. Veneers provide the exterior wall finish and transfer out-of-plane loads directly to the backing, but they are not considered to add to the load-resisting capacity of the wall system. Backing material may be masonry, concrete, wood studs or steel studs.

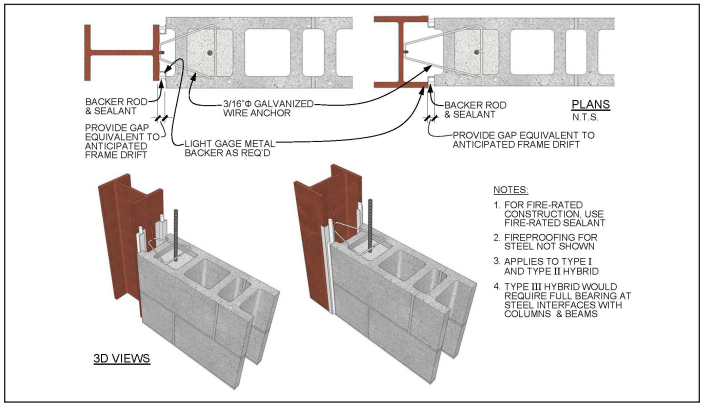

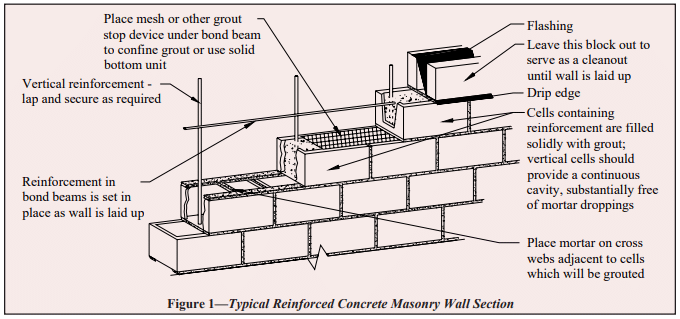

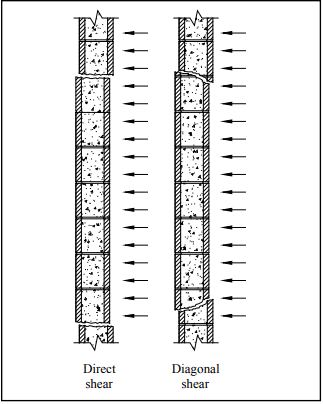

There are basically two types of veneer—anchored veneer and adhered veneer. They differ by the method used to attach the veneer to the backing, as illustrated in Figure 1. Unless otherwise noted, veneer requirements are those contained in the International Building Code (IBC) and Building Code Requirements for Masonry Structures (refs. 2, 3).

For the purposes of design, veneer is assumed to support no load other than its own weight. The backing must be designed to support the lateral and in some instances the vertical loads imposed by the veneer in addition to the design loads on the wall, since it is assumed the veneer does not add to the strength of the wall.

Masonry veneers are typically designed using prescriptive code requirements that have been developed based on judgement and successful performance. The prescriptive requirements relate to size and spacing of anchors and methods of attachment, and are described in the following sections. The assembly can be designed as a noncomposite cavity wall where the out-of-plane loads are distributed to the two wythes in proportion to their relative stiffness. Design criteria are provided in IBC Chapter 16 as well as in TEK 16-04A, Design of Concrete Masonry Noncomposite (Cavity) Walls, (ref. 4).

In addition to structural requirements, differential movement between the veneer and its supports must be accommodated. Movement may be caused by temperature changes, moisture-volume changes, or deflection. In concrete masonry, control joints and horizontal joint reinforcement effectively relieve stresses and accommodate small movements. For veneer, control joints should generally be placed in the veneer at the same locations as those in the backing, although recommended control joint spacing can be adjusted up or down based on local experience, the aesthetic requirements of the project, or as required to prevent excessive cracking. See CMU-TEC 009-23, Crack Control for Concrete Brick and Other Concrete Masonry Veneers (ref. 5), for further information.

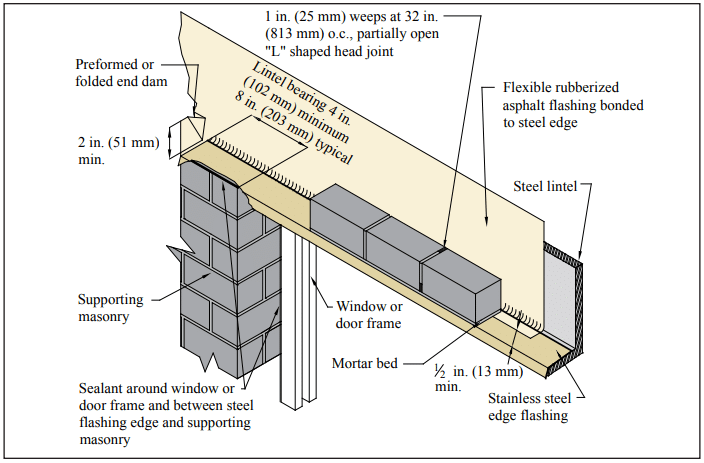

For exterior veneer, water penetration into the cavity is anticipated. Therefore, the backing system must be designed and detailed to resist water penetration and prevent water from entering the building. Flashing and weeps in the veneer collect any water that penetrates the veneer and redirects it to the exterior. Partially open head joints are one preferred type of weep. They should be at least 1 in. (25 mm) high and spaced not more than 32 in. (813 mm) on center. If necessary, insects can be thwarted by inserting stainless steel wool into the opening or by using proprietary screens. For anchored veneer, open weeps can also serve as vents, allowing air circulation in the cavity to speed the rate of drying. Additional vents may be installed at the tops of walls to further increase air circulation. More detailed information is contained in TEK 05-01B, Concrete Masonry Veneer Details, TEK 19-04A, Flashing Strategies for Concrete Masonry Walls, and TEK 19-05A, Flashing Details for Concrete Masonry Walls (refs. 1, 6, 7).

ANCHORED VENEER

Anchored veneer is veneer which is supported laterally by the backing and supported vertically by the foundation or other structural elements. Anchors are used to secure the veneer and to transfer loads to the backing. Anchors and supports must be noncombustible and corrosion-resistant.

The following prescriptive criteria apply to anchored veneer in areas with velocity pressures, qz, up to 40 psf (1.92 kPa). Modified prescriptive criteria is available for areas with qz greater than 40 psf (1.92 kPa) but not exceeding 55 psf (2.63 kPa) with a building mean roof height up to 60 ft (18.3 m). These modified provisions are presented in the section High Wind Areas. In areas where qz exceeds 55 psf (2.63 kPa), the veneer must be designed using engineering philosophies, and the following prescriptive requirements may not be used.

In areas where seismic activity is a factor, anchored veneer and its attachments must meet additional requirements to assure adequate performance in the event of an earthquake. See the section Seismic Design Categories C and Higher for details.

Masonry units used for anchored veneer must be at least 2 ⅝ in. (67 mm) thick.

A 1 in. (25 mm) minimum air space must be maintained between the anchored veneer and backing to facilitate drainage. A 1 in. (25 mm) air space is considered appropriate if special precautions are taken to keep the air space clean (such as beveling the mortar bed away from the cavity). Otherwise, a 2 in. (51 mm) air space is preferred. As an alternative, proprietary insulating drainage products can be used.

The maximum distance between the inside face of the veneer and the outside face of the backing is limited to 4 ½ in. (114 mm), except for corrugated anchors used with wood backing, where the maximum distance is 1 in. (25 mm).

When anchored veneer is used as an interior finish supported on wood framing, the veneer weight is limited to 40 lb/ft2 (195 kg/m2).

Deflection Criteria

Deflection of the backing should be considered when using masonry veneer, in order to control crack width in the veneer and provide veneer stability. This is primarily a concern when masonry veneer is used over a wood or steel stud backing. Building Code Requirements for Masonry Structures, however, does not prescribe a deflection limit for the backing. Rather, the commentary presents various recommendations for deflection limits.

For anchored veneer, Chapter 16 of the International Building Code requires a deflection limit of l/240 for exterior walls and interior partitions with masonry veneer.

Support of Anchored Veneer

The height and length of the veneered area is typically not limited by building code requirements. The exception is when anchored veneer is applied over frame construction. For wood stud backup, veneer height is limited to 30 ft (9.14 m) (height at plate) or 38 ft (11.58 m) (height at gable). Similarly, masonry veneer over steel stud backing must be supported by steel shelf angles or other noncombustible construction for each story above the first 30 ft (9.14 m) (height at plate) or 38 ft (11.58 m) (height at gable). This support does not necessarily have to occur at the floor height, for example it can be provided at a window head or other convenient location.

Exterior anchored veneer is permitted to be supported on wood construction under the following conditions:

- the veneer has an installed weight of 40 psf (195 kg/m2) or less,

- the veneer has a maximum height of 12 ft (3.7 m),

- a vertical movement joint in the veneer is used to isolate the veneer supported on wood construction from that supported by the foundation,

- masonry is designed and constructed so that the masonry is not in direct contact with the wood, and

- the horizontally spanning member supporting the masonry veneer is designed to limit deflection due to unfactored dead plus live loads to l/600 or 0.3 in. (7.5 mm).

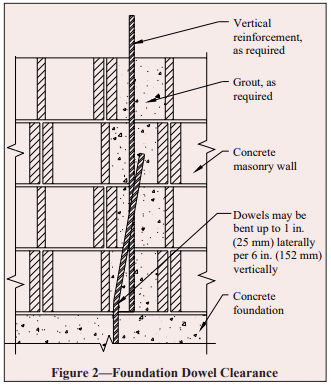

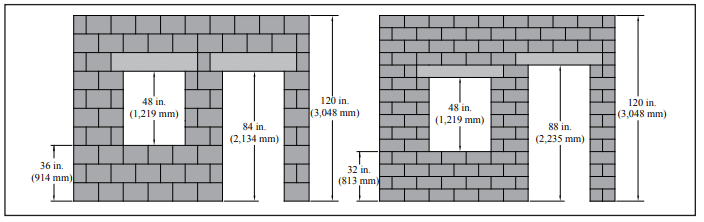

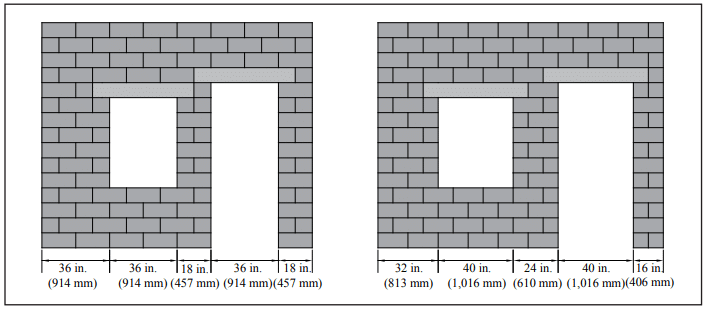

Over openings, the veneer must be supported by non- combustible lintels or supports attached to noncombustible framing, as shown in Figure 2.

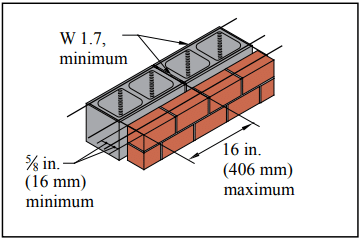

The following requirements assume that the veneer is laid in running bond. When other bond patterns are used, the veneer is required to have joint reinforcement spaced no more than 18 in. (457 mm) on center vertically. The joint reinforcement need only be one wire, with a minimum size of W1.7 (MW11).

Anchors

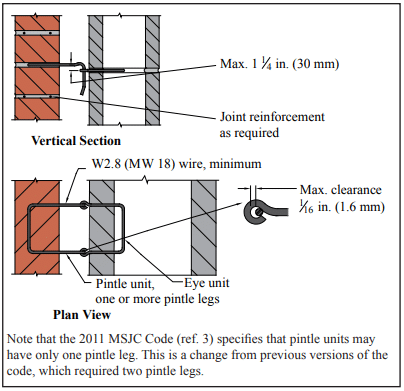

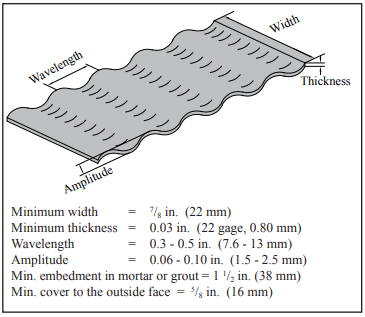

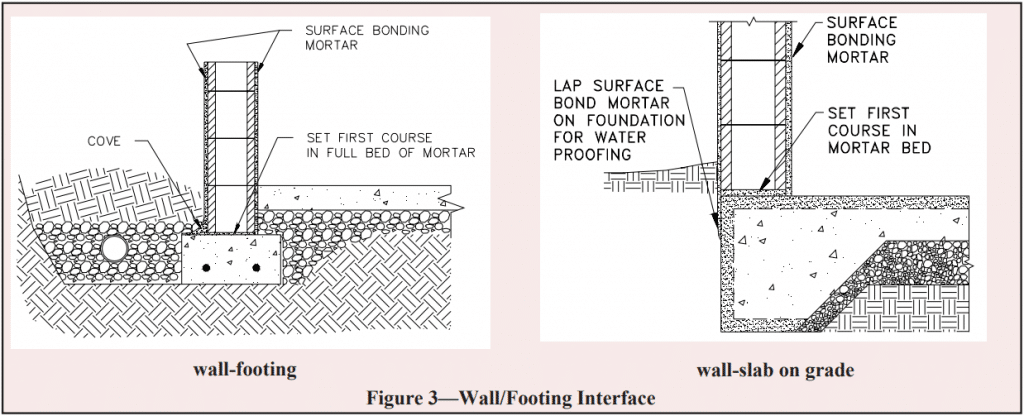

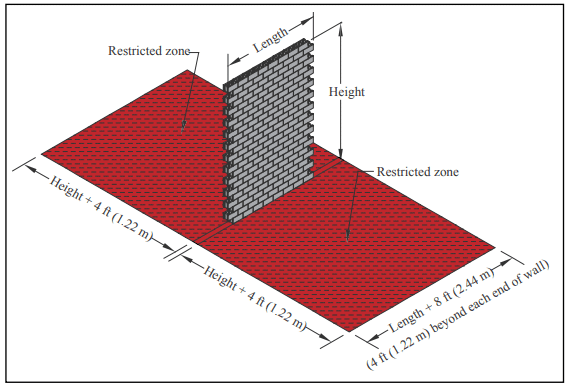

Veneers may generally be anchored to the backing using sheet metal anchors, wire anchors, joint reinforcement or adjustable anchors, although building codes may restrict the use of some anchors. Corrugated sheet metal anchors are permitted with masonry veneer attached to wood backing only. Requirements for the most common anchor types are summarized in Figures 3 through 5 and Table 1. As an alternative, adjustable anchors of equivalent strength and stiffness may be used. Cavity drips are not permitted. See TEK 12-01B, Anchors and Ties for Masonry, (ref. 9) for detailed information on anchor materials and requirements.

Attachment to Backing

When masonry veneer is anchored to wood backing, each anchor is attached to the backing with a corrosion- resistant 8d common nail, or a fastener with equivalent or greater pullout strength. For proper fastening of corrugated sheet metal anchors, the nail or fastener must be located within ½ in. (13 mm) of the 90° bend in the anchor. The exterior sheathing must be either water resistant with taped joints or be protected with a water- resistant membrane, such as building paper ship-lapped a minimum of 6 in. (152 mm) at seams, to protect the backing from any water which may penetrate the veneer.

When masonry veneer is anchored to steel backing, adjustable anchors must be used to attach the veneer. Each anchor is attached with corrosion-resistant screws that have a minimum nominal shank diameter of 0.19 in. (4.8 mm), or an anchor with equivalent pullout strength. Cold-formed steel framing must be corrosion resistant and should have a minimum base metal thickness of 0.043 in. (1.1 mm). Sheathing requirements are the same as those for wood stud backing.

Masonry veneer anchored to masonry backing may be attached using wire anchors, adjustable anchors or joint reinforcement. Veneer anchored to a concrete backing must be attached with adjustable anchors.

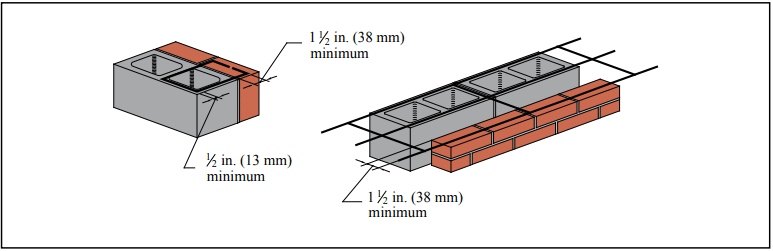

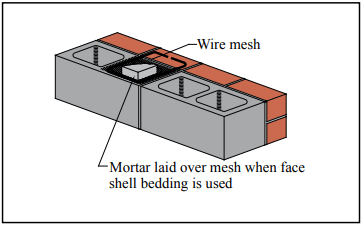

Anchor Placement

When typical ties and anchors are properly embedded in mortar or grout, mortar pullout or pushout will not usually be the controlling mode of failure. For this reason, connectors must be embedded at least 1 ½ in. (38 mm) into a mortar bed of solid units, and the mortar bed joint must be at least twice the thickness of the embedded anchor. The required embedment of unit ties in hollow masonry is such that the tie must extend completely across the hollow units (Figure 6). Proper embedment can be easily attained with the use of prefabricated assemblies of joint reinforcement and unit ties. Because of the magnitude of loads on anchors, it is recommended that they be embedded in filled cores of hollow units. To save mortar, screens can be placed under the anchor and 1 to 2 in. (25 to 51 mm) of mortar can be built up into the core of the block above the anchor (Figure 7).

High Wind Areas

In areas with qz greater than 40 psf (1.92 kPa) but not exceeding 55 psf (2.63 kPa) with a building mean roof height up to 60 ft (18.3 m), the following modified prescriptive provisions may be used.

The modified prescriptive provisions are:

- the maximum wall area supported by each anchor must be reduced to 70% of the value listed in Table 1,

- anchor spacing is reduced to a maximum of 18 in. (457 mm), both vertically and horizontally, and

- around openings larger than 16 in. (406 mm) in either direction, anchors must be placed within 12 in. (305 mm) of the opening and spaced at 24 in. (610 mm) on center or less.

In areas where qz exceeds 55 psf (2.63 kPa), the veneer must be designed using engineering philosophies.

Seismic Design Categories C and Higher

To improve veneer performance under seismic loading in Seismic Design Category (SDC) C, the sides and top of the veneer must be isolated from the structure, so that vertical and lateral seismic forces are not transferred to the veneer. This reduces accidental loading and allows more building deflection without causing damage to the veneer.

In SDC D, in addition to this isolation, the maximum wall area supported by each anchor must be reduced to 75% of the value listed in Table 1, although the maximum spacings are unchanged. In addition, when the veneer is anchored to wood backing, the veneer anchor must be attached to the wood using a corrosion-resistant 8d ring-shank nail, a No. 10 corrosion- resistant screw with a minimum nominal shank diameter of 0.190 in. (4.8 mm), or with a fastener having equivalent or greater pullout strength.

In SDC E and F, the requirements listed above for SDC C and D must be met, as well as the additional requirements listed here. The weight of each story of anchored veneer must be supported independently of other stories to help limit the size of potentially damaged areas. In addition, to improve veneer ductility the veneer must have continuous W1.7 (MW11) single wire joint reinforcement at 18 in. (457 mm) o.c. or less vertically, with a mechanical attachment to the anchors, such as clips or hooks.

ADHERED VENEER

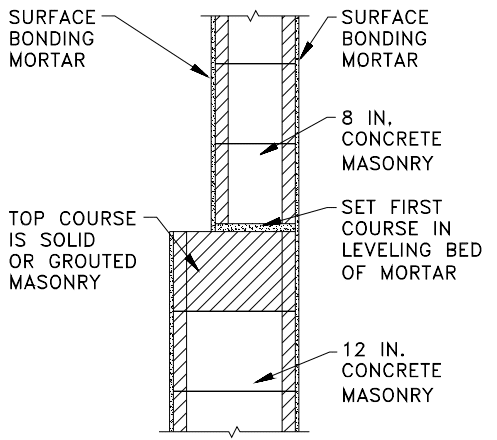

Conventional adhered veneer is veneer secured and supported through adhesion with a bonding material applied over a backing that both meets required deflection limits and provides for necessary adhesion. When applied to a masonry or concrete backing, the veneer may be applied directly to the backing substrate using layers of neat cement paste and Type S mortar, as illustrated in Figure 1. When applied over steel or wood framing, the adhered masonry veneer is applied to a metal lath and portland cement plaster backing placed against the sheathing element and attached to the stud framing members.

Alternative design of adhered veneer is permitted under the International Building Code when in compliance with Building Code Requirements for Masonry Structures (MSJC), where the requirements of unit adhesion (shear stress > 50 psi, 345 kPa) are met, out-of-plane curvature of the backing is limited to prevent the veneer from separating from the backing, and freeze thaw cycling, water penetration, and air and water vapor transmission are considered. Although the MSJC does not stipulate a deflection limit to control out-of-plane curvature, the Tile Council of America limits the deflection of backing supporting ceramic tiles to l/360 (ref. 11). Similarly, IBC Chapter 16 (for engineered design) requires a deflection limit of l/360 for exterior walls and interior partitions with plaster or stucco, which would be similar to an adhered veneer application.

Proprietary polymer-fortified adhesive mortars exist that meet the adhesion requirements and are used as a mortar setting bed to adhere the masonry veneers directly to a masonry or concrete backing, or to a lath and plaster backing system over wood or steel studs.

In addition, several proprietary systems are available to aid in placement of adhered masonry veneer on suitable exterior or interior substrates. These typically take the form of galvanized steel support panels that are mechanically anchored to a masonry or concrete backing, or placed against the sheathing element and attached to stud framing members. These products essentially take the place of the metal lath in the adhered veneer application. The metal panels contain support tabs and other features to facilitate the veneer application, carry the dead load of the veneer, and improve bonding of the veneer to the panel. In some cases, metal panel systems provide drainage or air flow channels as well. In lieu of mortar, construction adhesives having a shear bond strength greater than 50 psi (345 kPa) are used to bond the masonry veneer to the panel and masonry pointing mortar is used to fill the joint space between the masonry units. Installation using these products should follow manufacturer’s instructions.

Masonry units used in this application are limited to 2 ⅝ in. (67 mm) thickness, 36 in. (914 mm) in any face dimension, 5 ft2 (0.46 m2) in total face area and 15 lb/ft2 (73 kg/m2 ) weight. In addition, the International Building Code (ref. 4) stipulates: a minimum thickness of 0.25 in. (6.3 mm) for weather-exposed adhered masonry veneer; and, for adhered masonry veneers 2 used on interior walls, a maximum weight of 20 lb/ft2 (97 kg/ m2).

When an interior adhered veneer is supported by wood construction, the wood supporting member must be designed for a maximum deflection of 1/600 of its span.

Adhered veneer and its backing must also be designed to either:

- have sufficient bond to withstand a shearing stress of 50 psi (345 kPa) based on the gross unit surface area when tested in accordance with ASTM C482, Standard Test Method for Bond Strength of Ceramic Tile to Portland Cement Paste (ref. 10), or

- be installed according to the following:

- A paste of neat portland cement is brushed on the backing and on the back of the veneer unit immediately prior to applying the mortar coat. This neat cement coating provides a good bonding surface for the mortar.

- Type S mortar is then applied to the backing and to each veneer unit in a layer slightly thicker than ⅜ in. (9.5 mm). Sufficient mortar should be used so that a slight excess is forced out the edges of the units.

- The units are then tapped into place to eliminate voids between the units and the backing which could reduce bond. The resulting thickness of mortar between the backing and veneer must be between ⅜ and ¼ in. (9.5 and 32 mm).

- Mortar joints are tooled with a round jointer when the mortar is thumbprint hard.

When applied to exterior stud walls, the IBC requires adhered masonry veneer to include a screed or flashing at the foundation. In addition, minimum clearances must be maintained between the bottom of the adhered veneer and paved areas, adjacent walking surfaces and the earth.

Backing materials for adhered veneer must be continuous and moisture-resistant (wood or steel frame backing with adhered veneer must be backed with a solid water repellent sheathing). Backing may be masonry, concrete, metal lath and portland cement plaster applied to masonry, concrete, steel framing or wood framing. Note that care must be taken to limit deflection of the backing, which can cause veneer cracking or loss of adhesion, when adhered masonry veneer is used on steel frame or wood frame backing. The surface of the backing material must be capable of securing and supporting the imposed loads of the veneer. Materials that affect bond, such as dirt, grease, oil, or paint (except portland cement paint) need to be cleaned off the backing surface prior to adhering the veneer.

NOTATIONS:

l = clear span between supports, in. (mm)

qz = velocity pressure evaluated at height z above ground, in.-lb/ft2 (kPa)

REFERENCES

- Concrete Masonry Veneer Details, TEK 05-01B. Concrete Masonry & Hardscapes Association, 2003.

- 2012 International Building Code. International Code Council, 2012.

- Building Code Requirements for Masonry Structures, ACI 530-11/ASCE 5-11/TMS 402-11. Reported by the Masonry Standards Joint Committee, 2011.

- Design of Concrete Masonry Noncomposite (Cavity) Walls, TEK 16-04A. Concrete Masonry & Hardscapes Association, 2004.

- Crack Control Strategies for Concrete Masonry Construction, CMU-TEC-009-23, Concrete Masonry & Hardscapes Association, 2023.

- Flashing Strategies for Concrete Masonry Walls, TEK 1904A. Concrete Masonry & Hardscapes Association, 2008.

- Flashing Details for Concrete Masonry Walls, TEK 19-05A. Concrete Masonry & Hardscapes Association, 2008.

- McMican, Donald G. Is Flashing Dangerous Without a Drip? The Aberdeen Group, 1999.

- Anchors and Ties for Masonry, TEK 12-01B. Concrete Masonry & Hardscapes Association, 2011.

- Standard Test Method for Bond Strength of Ceramic Tile to Portland Cement Paste, ASTM C482-02(2009). ASTM International, 2009.

- Handbook for Ceramic Tile Installation. Tile Council of America, 1996.