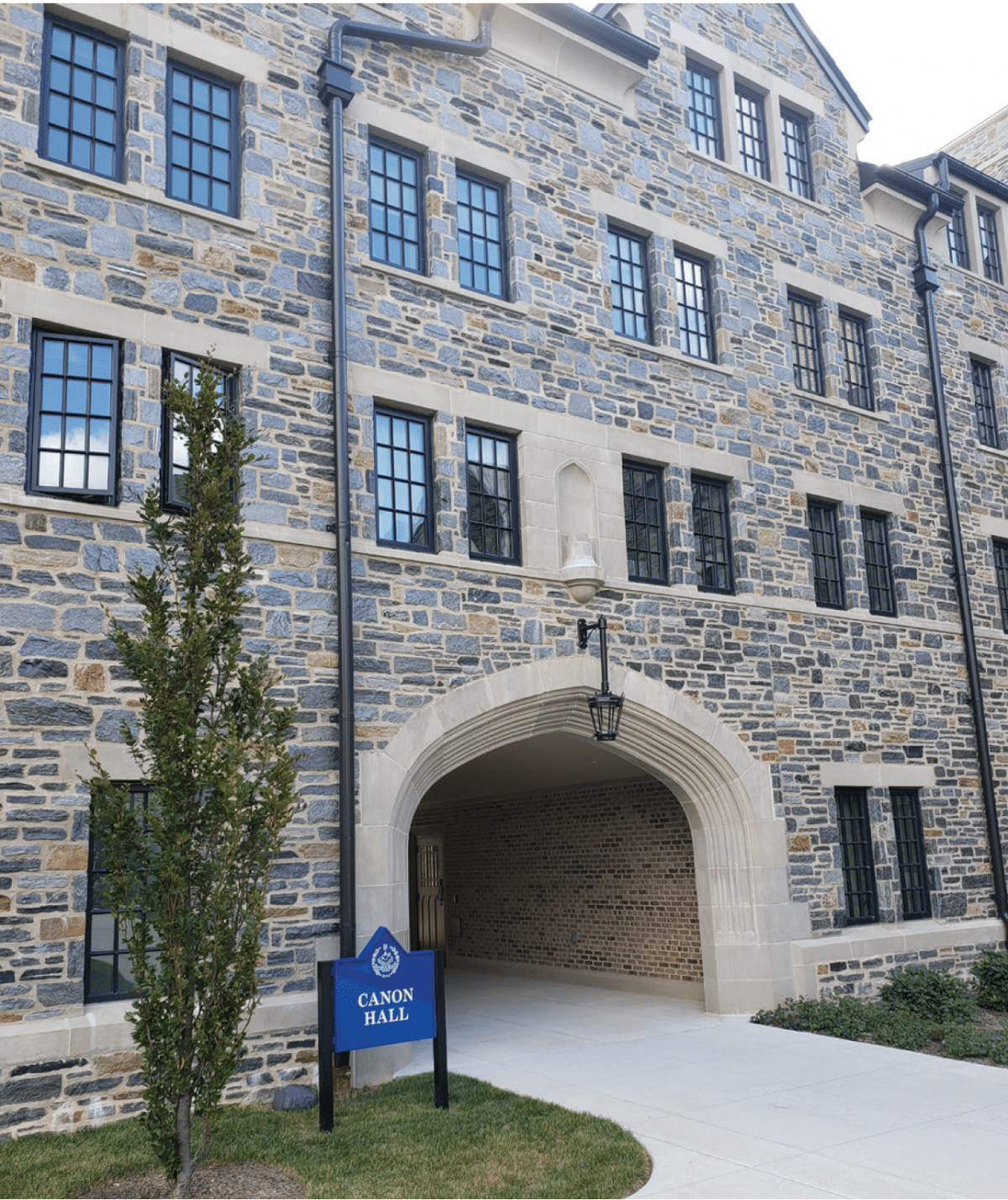

A high-tech, insulated concrete masonry wall system — along with a synergistic effort by the block producer, architect, engineers, contractors, industry experts, and the building’s owner — have created a state-of-the-art Vision Health and Wellness Center for The Central Association for the Blind and Visually Impaired (CABVI) in Syracuse, NY.

The building is a true testament to the power of simple, well-designed concrete masonry construction. It features a single-wythe, structural, integrally-insulated concrete masonry wall system, with exposed surfaces on both interior and exterior faces. The Vision Health and Wellness Center is a CMU success story of collaboration and innovation. The entire team — the building owner, architects, mason contractor, construction manager, and engineer, believed in a structural masonry solution. And that belief, and a lot of interdisciplinary cooperation, paid off handsomely.

CABVI, founded in Utica, NY in 1926, helps the blind and visually impaired achieve their highest levels of independence. The 26,000 sf Vision Health and Wellness Center is a multi-functional facility containing offices, living quarters, educational space, rehabilitation rooms, and a swimming pool. Rudy D’Amico, president and CEO of CABVI during the development and construction of the facility, says “the quality of this building exceeds all of our expectations. We have one of the top facilities in the country.”

And concrete masonry made that happen.

From Nine Layers and Four Trades To One and One

Rick Roach, president of Barnes & Cone, calls the project “a great example of the tremendous versatility of concrete masonry.” According to Roach, the first design concept involved steel frame construction with masonry veneer, exterior insulation board, exterior sheathing, light gauge metal studs, batt insulation within the studs, vapor barrier, gypsum board interior, and paint.

But Bill Ferraldo, principal of Harmony Architectural Associates, wanted a simpler system without the complexity of all the layers and multiple trades. Ferraldo notes that “performance problems always originate within the layers. And with so many trades involved with installing those layers, solutions to problems become difficult.” He wanted structural masonry if it could be brought in for the same budget as the preliminary steel frame design. The new budget, and the actual bid, came in under the original budget

Barnes & Cone is a member of the Concrete Products Group (CPG), a nationwide organization of CMU producers that pool their resources to fund innovation and market development. So, in addition to working with the architect, client, and mason contractor, they were able to work closely with David Biggs, a consultant to the organization and the author of the CPG Spec-Thermal Structural Design Manual. Biggs also consulted with Jeremy Fudo of IPD Engineering on the structural considerations of using the Spec-Brik Hi-R H System. Roach is also quick to praise Jason Thompson, NCMA’s vice president of engineering, who also contributed technical expertise to the project. “These are the times when our membership and involvement in NCMA really pays off for us. It’s one of the best investments we make as a company.”

Challenge – Single-wythe energy efficiency

Solution – Integrally-insulated concrete masonry units

“This building is loaded with CMU innovation,” Roach said. “It really shows how well block can perform on structural, thermal performance, and aesthetic levels. Two new lightweight, high-performance, pre-insulated CMU were invented for the project. We used concrete masonry lintels, reinforced with carbon fiber. We worked with the CABVI to develop special colors for the concrete masonry units that are more easily readable by the visually impaired. We used a computer program to help optimize the layout of the block in terms of the building fenestration. We used single-web block in the foundation, making reinforcing and grouting easier and better. We pushed the envelope on every level.”

To help make it happen, Barnes & Cone turned to Dave Nickerson, inventor of the first pre-insulated concrete masonry unit in 1971. In a collaborative effort, two new pre-insulated units were developed for the project: a 12” x 4” x 16” CMU (trade name “Hi-R H Spec-Brick”), with an R-value of 15.5, and a 12” x 4” x 16“ CMU jamb unit (trade name “Hi-R H Jamb”), with an R-value of 12.1. Dr. Isaac Berger of The California Institute of Electronics and Material Science conducted a second-party review, verifying that thermal calculations complied with ASHRAE Standards. While Nickerson passed away shortly before construction began on CABVI, he lived to see his block produced and renderings of the building.

One Mason Takes The Place of Four to Six Different Trades

Challenge – Simplify control layers and expose masonry

Solution – Innovative CMU system meeting multiple needs

“These systems are innovative,” Roach says. “A mason can install one 11 5/8″-wide wythe of solid-grouted masonry in place of nine different layers of material installed by four to six different trades. One single layer of Hi-R H masonry delivers engineered load-bearing masonry walls, along with thermal mass performance that can exceed R-16 using lightweight mix designs. You also get a solid-grouted moisture barrier wall requiring no in-wall flashing or weeps — a wall that is four-hour fire-rated, has a beautiful Spec-Brik concrete masonry interior finish, and a whole lot more. Bill Ferraldo said it best: It’s ‘one and done.’”

Ferraldo and Dave Colgrove of Harmony Architectural Associates have a long history with mass construction, and they recognized the thermal value of the exposed concrete masonry interior surfaces. The building is heated with geothermal heat pumps, and the mass and the integrally insulated masonry walls reduce temperature swings inside. “It’s classic durable masonry. This integrally insulated CMU system lets us design with masonry in a way we haven’t been able to design in a long time.” Ferraldo said.

Innovation From the Bottom Up

Creative structural design begins from the bottom up, according to Roach. The foundation used 12” x 8” x 16” single-web block — a first in New York State. The open ends of the block made unit placement easier than usual because masons didn’t have to lift the block over the top of vertical reinforcement. Without the typical obstructions found in two-core, three-web block, the open core design also allowed quick grouting of the walls. There was very little grout settlement while the grout was being vibrated.

Challenge – Simplify modular design and coordination

Solution – BIM and MasonryIQ

The many windows in the facility made a modular design critical for efficient labor, and Biggs suggested using Masonry IQ, a computer program that works with Building Information Modeling (BIM) systems that automates masonry layout. The New York State Structural Masonry Coalition provided a grant that made that happen. Mike and Nick Palmer of Remlap Construction, the mason contractor, were brought in to confirm that control joint and vertical bar layout around openings would facilitate the fastest speed of construction possible.

Challenge – Masonry lintels without formwork

Solution – Prefabricated masonry lintels

The project also saw the first New York State installation of Bigg’s pre-fabricated masonry lintels with carbon fiber reinforcing material. Remlap Construction built the lintels in Barnes & Cone’s plant, and they were then delivered to the job site, lifted into place using a forklift, and set on a bed of mortar, ready to receive reinforcing steel, grout, and the masonry courses above

Attention to Quality All the Way Through

Quality installation was essential to the project’s success. The single-wythe system meant the units were exposed on both the interior and exterior of the structure. Many were exposed on three sides — two faces and the end. Remlap Construction took special care to keep mortar joints full, plumb and true and mortar color consistent.

“Really, there were three driving forces that made this project a grand slam — collaboration, innovation, and quality construction. I can’t overemphasize the fact that this was a total team effort. The client, the architect, the engineers, special consultants, and the contractors were all on the same page. We were all working together and looking for ways to innovate and be more efficient for the people at the Vision Health and Wellness Center” said Roach.