10 Ways To Create Seamless Indoor-Outdoor Transitions

As more homeowners seek to expand their outdoor living spaces and connect closer to nature, blurring the lines between interior spaces and outdoor living areas is increasingly important. Incorporating materials like stone, steel, and window walls can ensure these indoor-outdoor transitions are not just functional, but also aesthetically stunning.

Creating seamless transitions between the interior and outdoor living spaces is rooted in our desire to merge the comforts of the interior with the beauty of the exterior. This design approach can maximize natural light in the home for a warm and inviting atmosphere, expand the living area, enhance occupant well-being by infusing nature into daily life, and foster visual continuity.

Here are a few design and material strategies to consider as you develop seamless connections.

Leverage the Authenticity of Stone

With its natural appeal and durability, stone is a favored choice for creating harmonious indoor-outdoor transitions.

- Stone Flooring: Using the same type of stone for indoor and outdoor flooring can establish a visual flow that seamlessly bridges the gap between spaces. It’s especially effective when the stone extends from the living room to the outdoor patio or terrace. Porcelain tile is a common choice, and you can even select different traction on the surface of the porcelain tile and porcelain outdoor pavers.

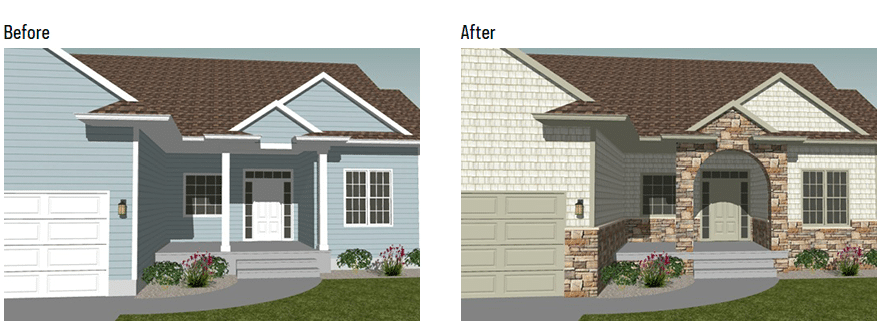

- Stone Accent Walls: Manufactured stone veneer walls, whether indoors or outdoors, serve as focal points that unify the spaces. Whether it’s a grand fireplace in your living room or a stone accent wall around the patio or outdoor kitchen, each adds texture, character and warmth.

- Outdoor Stone Features: Incorporating stone veneer into outdoor features like fireplaces, kitchens, or seating areas enhances functionality and aesthetics while providing a visual connection to the interior.

Infuse Modern Elegance with Steel

Steel is a contemporary material choice that brings a sense of modernity, strength, and sophistication to seamless transitions.

- Steel Framing for Window Walls: Steel-framed windows and doors, often featuring large glass panels, are a hallmark of modern design. They provide both visual impact and structural integrity, allowing for slim profiles that maximize views and natural light.

- Steel Railings and Screens: Steel can be used for railings and screens on balconies, terraces, or patios, both indoors and outdoors. These elements create a sense of openness while ensuring safety and privacy.

- Steel Staircases: Combining form and function, floating steel staircases can connect different levels of the home while maintaining an open, airy feel.

Embrace the Transparency of Window Walls for Indoor-Outdoor Transitions

Perhaps the most vital element in crafting seamless indoor-outdoor transitions is the use of window walls. These expansive glass structures erase the boundaries between indoor and outdoor spaces, allowing for uninterrupted views and connections to nature.

- Floor-to-Ceiling Windows: Maximizing natural light and views, floor-to-ceiling windows create a dramatic effect. They allow you to fully appreciate your outdoor surroundings from the comfort of your interior.

- Sliding Glass Doors: Sliding glass doors are a practical choice for connecting indoor and outdoor spaces. They are user-friendly and can be fully opened to merge the areas.

- Corner Windows: Corner windows, often referred to as “glass corners,” are a symbol of modern design. They provide panoramic views and serve as stunning architectural focal points.

Striking the Right Balance

When considering options for stone, steel, and window walls, it’s of course important to balance both aesthetics and functionality. This includes:

• Climate: Ensure the outdoor living space remains usable year-round; this may include adding climate control elements like heaters or fans.

• Privacy: Wide open transitions can create privacy concerns. Incorporating thoughtful landscaping, retractable screens, or clever architectural features to address this issue where needed.

• Maintenance: When selecting materials, be sure to factor in their required upkeep in these settings, which can make a big difference in the aesthetics and durability.

When executed thoughtfully, seamless indoor-outdoor transitions can help blur the lines between the built environment and the natural world. Consider these concepts for creating a living space worth returning to again and again.

A version of this blog originally appeared on the Creative Mines blog.