Herndon, VA – Four college teams presented their unique, fresh concrete masonry unit (CMU) designs at the 2020 Unit Design Competition (UDC) during NCMA’s virtual Midyear Event. Judges reviewed and scored the designs and results were announced during the live online event.

The team from North Carolina State University took the top prize over second place Mississippi State, third place Iowa State and honorable mention Ball State.

Due to COVID-19, last minute changes were implemented to keep the competition in play. In lieu of physical story boards and prototypes, students were asked to submit video presentations to allow for an online jury to evaluate.

“Fantastic video presentations” said Jason Thompson, UDC’s Structural Engineer Judge. “These students have a second career in multi-media and graphics.”

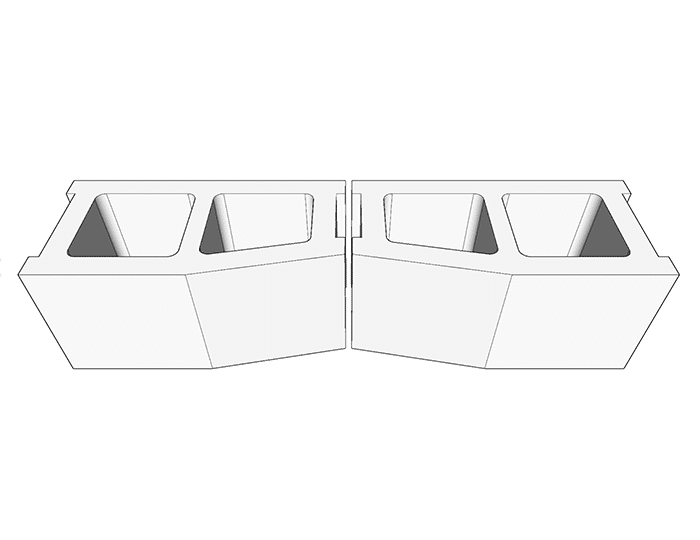

The team of Joshua Albert and Clayton Johnson, all students at North Carolina State University in Raleigh, North Carolina under the tutelage of Professor Vincent Petrarca, took first place. The team’s design, dubbed “Chock Block”, wowed the judges with its highly practical design that can easily incorporated into construction using conventional CMU.

Designed in response to traditional CMUs, Chock Block is a simple, extruded concrete masonry unit that improves the visual experience of concrete masonry while integrating into existing CMU masonry and making no structural compromises. Chock Block is a part of the team’s Angle Face series with the Point and Valley blocks, a collection of blocks sharing a single change, a single move in form, versus traditional blocks. By organizing the angled faces of our blocks, a textured finish that plays with shadow is achieved, an effect amplified with integral coloring. The blocks are efficient to produce, ship, and install, and can easily become more than an accent at little to no extra cost. Through a modest change in design, the team was able to respect concrete masonry as a system and produce remarkable results.

*Note: Video does not have sound.

Second place in the competition was claimed by a team from Mississippi State University in Starkville, Mississippi under the guidance of Professor Jacob A. Gines. They were helped along through vital manufacturing and consulting assistance from Fred Dunand, president of Saturn Materials out of Columbus, Mississippi.

Jackson Harrell, Caya Perry, Ruth Southall and Jon Zeipen presented their design, “Void” while also showcasing their applied skills. The jury loved the hands-on prototyping of the units. Provided not just great visuals, but real-world, practical engagement for the students.

Their design goal was simplicity in form and execution. They wanted to create a concrete masonry unit with one graceful gesture. The concrete unit features a hole which runs the short length of the brick. The second goal of othe design was to create a unit that’s purpose extended beyond aesthetics. Throughout the design process, the team noticed the possibility of an acoustic effect through the horn shaped hole of the unit. After some investigation, they found out that the shape of the hole created unique acoustic opportunities that were not currently addressed in the market.

Coming in at third place was the foursome, Jonathan Kaye, Bill Le, Nathan Nall, and Shivang Patel, with direction from Professor/Advisor Bosuk Hur from Iowa State University in Ames, Iowa with their innovative “INTER(B)LOCK” design. INTER(B)LOCK’s columns impressed the jury and they felt the columns would be a perfect central features to any space…interior or exterior…providing structural function and a novel aesthetic texture.

The INTER(B)LOCK is an exploration into CMU’s detail and relationship with natural phenomena. INTER(B)LOCK’s lock and key modules interlock together in an effort to improve upon CMU’s qualities of modularity, simple production, and scalability by introducing new methods of construction while respecting manufacturing constraints. The modules manifest as curved block forms, inspired by inquiry into the movement of water, air, light, and green nature across time. INTER(B)LOCK’s intentional curvature provides a soft visual texture and enables new forms of manipulation across axes, typologies of existing use cases, and structural and mechanical system integration.

The team of Collin Beresford and Allison Loth, with counselling from Professor Tony Costello, of Ball State University in Muncie, Indiana rounded out the competition with an honorable mention for the groundbreaking “Breeze Block” unit. The judges felt the unit had unique versatility. Few units can function equally as a screen wall and as a permeable paver.

The Breeze Block’s design addresses the issue of insufficient CMU construction methods that exists in Haiti and many other developing countries. The incorporation of recycled water bottles is not only a sustainable strategy, but is also a method of passive cooling in the design. Especially in hot, humid climates like Haiti this will be extremely beneficial in creating thermally comfortable spaces for people to gather. The water bottles will have the bottoms removed and extend the full depth of the masonry unit allowing air to pass through the smaller opening at the mouth. Air is condensed as it moves through the shaft of the bottle which increases its speed and produces a cool breeze. This is also known as the Venturi Effect. The remainder of the recycle water bottles that are not used for passing cooling would be ground up and added to the aggregate. One final strategy incorporated into this CMU design is the use of the arch. This not only secures the water bottles in place, but benefits the structural integrity of the brick as well.

Click here for more information on the NCMA Foundation and the Unit Design Competition.

Click here for a PDF version of this press release.

The NCMA Education and Research Foundation mission is to advance and support the concrete masonry and hardscape industry and the public interest through research and educational programs designed to meet the future needs of the industry.