An Award-Winning AIA Architect on Why she Loves Building With CMU

“It’s so flexible, CMU. It’s a very easy material to make work. As an architect that builds many different types of buildings, it’s a nice material to use for creating new ideas because it is so flexible.”

Joyce Owens FAIA RIBA is the principal architect at Studio AJO, which is based on Main Street in Fort Myers, Florida. Her client list extends not only throughout the United States but also to the United Kingdom and Italy.

Before opening in Florida, Owens was a co-founding partner at the London-based firm Azman Owens Architects, where she worked with clients like now-British Prime Minister Boris Johnson, fashion gurus Alexander McQueen and Isabella Blow and many more.

Her work has received accolades and awards from the UK’s Royal Institute of British Architects (RIBA) and AIA, too. She’s been published in The New York Times, the Sunday Times in London, Elle Magazine and several other esteemed publications. She was also an architectural columnist for the Fort Myers News-Press and USA TODAY.

In 2017, she was the president of the AIA Florida.

Via the phone she recently talked with NCMA openly about her career and why she is “a big masonry fan.”

On how her career moved abroad and then back again:

“I lived and worked in Florida a while and we used CMU a lot because in commercial building 30 years ago when I was there, working with masonry was a good choice with commercial building. But we weren’t really using it with residential. We had moved away from it. Because originally in the 1950s and 1960s — the mid-century — they used masonry all the time so we moved away from it for a little bit.

“But when I moved to England I started using masonry a lot, and bricks as well. So it wasn’t just CMU. But we used it extensively because when you build there you build for durability. You really build for durability.

“When I came back to Florida, I started doing a lot of residential work. I do commercial work as well — but I found that on the islands where we were building, they were still using timber. So I started pushing these houses on the beach to be built with CMU and now we use CMU almost exclusively. We don’t even use wood pilings anymore.

“I’m finding that, on the beach, it’s a much stronger way to build.”

What do you see for coastal areas for the future?

“I think that masonry is going to be the answer moving forward if we want to build strong in coastal areas. We really have to be building with CMU. As opposed to putting pressure-treated pilings in the ground — it’s much better to do that with CMU in the ground. And then even as you go up, even if some moisture comes through, outside the block, it seems to handle better than wood does.”

What about from working with it from a pure design point of view?

“It’s so flexible, CMU. It’s a very easy material to make work. As an architect that builds many different types of buildings, it’s a nice material to use for creating new ideas because it is so flexible.”

How has building in Florida changed over the decades?

“In Florida, everybody thought that ‘oh, it’s really easy to build in Florida because it’s just hot and warm, that’s not a problem.’ But what they didn’t realize is that it’s very humid in that climate and you can’t build the same way you as you do in California, for example. It’s a whole different way of building. So now they’re realizing that if you want your buildings to last in Florida, you have to build really well.

“I was in Boston two weeks ago and I went to look at an amazing campus that was all built in concrete by a very famous architect, and they were working on the master plan to build dormitories for the campus that was built in the 1960s. And I couldn’t believe they were building wood-framed dormitories in that climate. It just seems crazy to me to do that on a campus that was perfectly intact after all those years. The concrete had lasted very well. Of course it needed updating just like all buildings, but I couldn’t believe they went that way. And it was happening right in front of us. It just seemed like a mistake.

“So I have to say, not everyone is building for durability.”

“[CMU] is much stronger, it’s much more durable. It’s much less susceptible to rot. It may be more expensive but it’s going to take less maintenance and it’s going to outlast timber.

“And I’m not against wood, but it just needs to be considered for its place.”

On the expression ‘value engineering’:

“In construction there’s a term that we use when we want to make things less expensive. So you might say ‘if we use another product — let’s say we’re using trim woods on the outside — if we use another product we might save 50 percent on our material cost.’ Or ‘if we don’t use this expensive air conditioning system that’s ten times more efficient but use this less expensive system that’s only five times as efficient, we’ll save money.’ So those are value engineering decisions that you make typically after the building has been designed and priced. So it typically comes after bidding.

“I’m sure it happens when you’re making that decision with your client, ‘do we build with masonry or do we build with wood?’ And then you value engineer the masonry out, and instead you go with wood.

“So somebody said to me the other day, which I thought was quite clever, about the idea of value engineering that it’s only value engineering if there’s real value you’re taking into the project. So sure, you’re going to go to wood instead, but in the long-term, is there real value in that? Does the client understand the long-term effects of choosing wood over masonry?

“And I’m not saying anything bad about wood, it has its place. I’m not ragging on it in any way. It’s a great material as well, which they’re making very sustainable. And that’s part of my bugbear with the masonry, which is that they have to work harder now to make their product more sustainable. I really try to push that when I give my talks. Now is the time for the masonry industry — because they have a great product — to make CMU and other masonry materials ‘carbon zero.’ If that can be figured out, concrete products would be used all the time in building.”

On climate, and where AIA is headed:

“I’m very involved with the AIA. And I’m currently on the strategic council. So I very much have my finger on the pulse of what AIA is doing as a national association. And we’ve always been committed to good building practices and addressing climate issues but in the next five years — as the decision was made just this year — all of our resources are going to go toward climate matters. We’re literally taking a look at all of our programs and refocusing them. We’re not going to get rid of all of them, but we’re going to put an emphasis on this whole climate action issue and how we address change and flooding and the rain that comes from all of our big storms. This is going to be very important.

“When I spoke recently in front of the masonry institute in California I said what you can do right now — and they seemed very interested in — is they can team up with the AIA to work together with some of their programs that are already in place to prove and show — alongside the architects — that their material is the best out there to address all of these climate action issues.

“We want you to be our partner in this. We want to work with you. The channels exist and the connection — on a national level — can happen again.”

For more on Joyce Owens and her work, click here.

2019 Hardscape North America Raises the Bar Once Again

Each year, the Hardscape North America (HNA) joins GIE+EXPO at the sprawling Kentucky Exposition Center for North America’s largest event for landscape and hardscape professionals.

With over 18,000 total attendance at the combined HNA and GIE+EXPO event, hardscape industry presence at North America’s largest landscape expo continues to grow. Contractor attendance at HNA, an Interlocking Concrete Pavement Institute (ICPI) event, and GIE+EXPO jumped 12 percent this year, with more than 15,532 landscape and hardscape professionals in attendance.

The Hardscape North America annual event presents a unique opportunity to reach contractors, designers and municipalities with an interest in hardscape industry products and services. A new “Hardscape House” pavilion hosting numerous hardscape demonstrations and the HNA Installer Championship was a popular attraction throughout the event.

Education Courses, Certification Testing and Workforce Development programs at HNA provide enormous opportunities for career growth. Highlights of this year’s education program included sessions on leveraging online reviews to grow a hardscaping business, improving profitability, and a discussion on finding the next generation of hardscape installers. Each session provided participants with ideas they can use right away to make a positive difference in their business.

Dealer-exclusive expo hours, training and networking events received high marks from HNA dealer attendees. Dealers participated in roundtables that were deeper dives into topics including using contractor programs as a business growth tool, inventory control, and drafting new talent into the business. Other sessions included differentiating your business, top-notch customer service, and upselling.

“HNA gets bigger and better each year, reflecting ICPI’s industry achievements and the growing demand for segmental pavement systems, segmental retaining walls, natural stone, and hardscapes,” said Charles McGrath, ICPI’s executive director. “A growing market is creating expanded opportunities for hardscape contractors and dealers, and HNA is North America’s biggest event of the year for these professionals.”

In addition to the trade show floor, HNA featured:

Outdoor hardscape demonstrations in a continuous build format

Numerous installation and business educational opportunities for contractors

A program exclusively geared towards helping dealers and distributors grow their businesses

The Hardscape North America Installer Championships with 13 teams competing from the United States and Canada

The 2019 HNA Hardscape Awards, which honor projects by contractors building residential walkways, patios, driveways, commercial plazas, parking lots, and streets using concrete pavers, clay bricks, segmental retaining walls, and a combination of hardscape products

HNA 2020 is scheduled for October 21-23. For more information, visit www.HardscapeNA.com.

Date November 6th, 2019

Tell Your Hardscape Story

ICPI and NCMA have partnered to create @hardscapingis, a social media handle on Instagram designed to reach 17-20-year-olds and show them opportunities in the hardscaping industry. Here’s how to tell your story to the next generation:

Follow @hardscapingis on Instagram.

Engage with @hardscapingis – like, comment, and repost.

Make posts on your account that show the “behind the scenes” of your work (hard work and fun), your personal journey into hardscaping, your personal life and success, etc. Use hashtags when possible (#money, #business, #success, #hustle, etc.) and tag @hardscapingis in your posts.

And when networking with others in the industry, tell them about @hardscapingis!

DATE November 6th, 2019

How CMU Allowed an Architect to Design One of the Five Safest Schools in America

“First and foremost they wanted something that was going to be timeless – a classic design. And they wanted something that was going to be secure for the students. Part of that is durability – the wear and tear on middle schools is pretty tough, so concrete block was a ‘no-brainer’ option.”

When architect Calvin Durham and his team at Lambert Ezell Durham Architecture in northern Alabama were tasked with designing the new middle school in their hometown of Florence, they knew right away that they could draw upon structures of the past.

The 180,000 square-foot space is a partial Tuscan ode — design-wise — to the former Appleby School, which opened in 1917 and was eventually replaced in 1951.

“We used some of that detailing and some of that ‘feel.’ We didn’t copy it so much as we used that same vernacular of elements to kind of draw back on,” Durham noted.

What he and none of his associates on the project expected however, was for one of the most renowned voices in the world on the subject of school safety to proclaim their new structure one of the most secure schools he’s ever encountered.

“I was blown away,” said Durham.

Michael Dorn, executive director at Safe Havens International, the world’s leading international nonprofit campus safety center, told Durham’s firm that of the 7,800 schools he’s reviewed, Florence is in the top five.

Finished in February 2019, the new educational facility — which Durham admits often gets mistaken by onlookers as part of the nearby university, Northern Alabama — is secure for a number of reasons. Clear sight-lines, electronically-controlled public access are a few and part of the equation, but all of these are state-of-the-art technological features are made possible and secure because of its strong central structural system — a smart design that ties exterior student spaces to their interior counterparts.

“When the school day begins and class is in session, there are only two doors that are open. That’s the front ‘bus drop’ door and the back ‘passenger car’ door. Once the bell rings, everything locks down with a magnetic lock so that everything with the exception of the academic building’s front entry — which is the formal entry — is secure,” said Durham.

“Those doors won’t look until after school ends but should you pass through them you enter a foyer but can go no further. It’s basically a locked vestibule. So they have a lot of control of who comes and who goes and the first person one would meet should they be allowed to exit out of the foyer is the safety resource officer — a police officer.”

Perhaps its crown jewel is a gymnasium comprised of concrete masonry units (CMU) that doubles as a FEMA-rated storm shelter accommodating three times the school population.

“We’ve done a lot of schools that have done extremely well with concrete block, ” said Durham, who noted that Echelon Masonry was their block supplier for this particular project. “We’re really proud of this one.”

The design centers around a commons, an area that connects academics, fine-arts as well as athletics “while also serving as a pre-function space for public events”, according to the firm.

“The academic wing’s prominent two-story facade was placed west [of the commons], taking advantage of traffic visibility along the campus’s west edge, while wrapping itself around an outdoor courtyard with controlled access.”

“The auditorium, north of the commons, anchors the fine-art wing surrounding it. It hosts public events year-round, thus optimum professionally-designed acoustics were provided. The gymnasium, east of the commons, aligns with the existing high school competition gymnasium, allowing their simultaneous use for tournaments/events.”

Additional features include, collaboration spaces, central locker area, cafeteria seating options, including outdoor dining.

The construction cost for the entire project came in at about $34.6 million, with a building area of 180,000 square feet ($192 per square foot).

But it’s not just the local community, Dorn, and those at Durham’s firm that are pleased with the final, finished product. Recently it was awarded the 2019 Top Block Design Award by the Alabama Concrete Industries Association at this year’s North Alabama Chapter of the American Institute of Architects (AIA) Design Awards — an honor so prestigious that it’s given to just one project per calendar year.

In the Times Daily, Association president John Sorrell called the school “timeless and will still look great in the next 10 or 20 years and not feel dated.”

“We were trying to keep a low maintenance and high durability structure, and obviously block is ideal for that scenario as long as it’s maintained, which this school system does a really good job of doing,” said Durham.

For more information on AIA North Alabama, go their Facebook page.

6 Big Ideas You Missed at the YPG Workshop (and Why You Should Never Miss One Again)

“A piece of advice for those entering in this industry? Respect. You see a lot of people in this industry that are different from those you might see coming out of college. You might have people that can barely use Microsoft Excel but at every other technical point in their job they’re simply brilliant. Don’t judge a book by its cover. Learn from them. There’s decades of information that can go wasted if you don’t.”

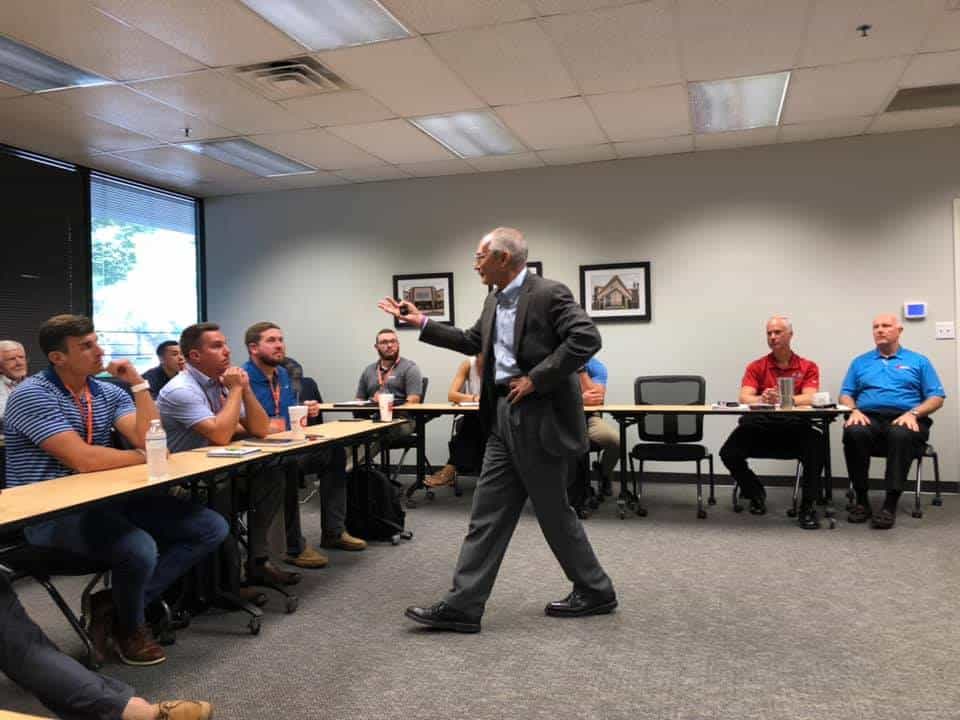

Drew Helon offers this to a room full of his peers — otherwise known as YPs, short for “Young Professionals” — while just outside the window the enthusiastic Georgia sun bakes the air. It’s the middle of September. They’re at the headquarters of ACM Chemistries, Inc., just outside Atlanta, for the group’s fall workshop.

The anecdote, as well as the ones that ensue, is met with smiling faces and a popular emoji.

“The biggest thing I think for me and a lot of us here is this networking opportunity,” says Zach Boyd. “The more people you get to know through these events that have experienced and solved similar issues — tech, sales, whatever it maybe — the better you’re going to be at your job. And it’s as simple as talking with one another. There’s so much power in sharing knowledge and experiences.”

“It’s just one of the NCMA resources that allows me to help my customers and ultimately drive sales for our company.”

“The network really does help,” says Emma Rustico. “I had an instance where I ran into an aggregate issue and I was able to reach out to one of my connections that dealt with aggregates and the problem was solved a lot less painfully and in a lot less time.”

The guest speakers throw a lot of fastballs. They’re industry veterans and experts that address the small crowd like chummy acquaintances. They’re not lecturing. They’re passing along.

***

The experience the workshop provides must be just that: experienced. There’s a reason people go to the theater.

Guest speaker and industry maven Bobby Staten tells about the time his team decided to do something they never did before: get every sales person in the same room, once every quarter. The results, he says, were astounding.

“The ROI is hard to pinpoint but trust me: it’s invaluable. That sharing of information — each time you come away with things you never realized before.”

In no particular order, here’s a shortlist of ideas that were explored in depth during the two days in Atlanta.

No matter what you do, no matter who you are, you need a coach. Don’t think so? Steve Jobs, Jeff Bezos, Larry Page, Sergey Brin, Sheryl Sandberg and Marissa Mayer would all disagree (they had/have coaches). “No one is good at seeing themselves as others see them,” said Alan Ketzes, a guest speaker at the workshop who is a coach to dozens of CEOs in the United States. “Coaching is becoming a major part of business now. Bill Gates says that everyone needs a coach. And it’s all about where you want to go, not the coach. They ask better questions, and explore you on your answers.”

Atul Gawande, a successful surgeon and The New Yorker contributor, agrees.

“The pedagogical view was that was professionals can manage their own improvement and growth — it’s the old trusted view. But sports takes the other opposing view, that no matter how good you are, you need a coach.”

And sports, as it often does, has a great point.

Consensus building can take you from being a manager to being a leader. You lead people, you manage things. People don’t want to be managed, they want to be lead — they want to follow a leader.

“A leader always builds consensus,” said Bobby Staten. “They get everyone’s opinions and make an informed decision afterwards. It’s so much easier when everyone can say ‘hey, at least they listened to me’ — even if they might not agree with the outcome.”

A mission statement is not a vision. It’s important to know this, because you’ll need both if you’re trying to establish a successful business. A mission statement is something you put together to give every member of your team a plan on what goals you’re aiming to accomplish on a day-to-day, week-to-week basis. It also involves a layout of how you’re going to do so. A vision statement, however, is a snapshot of what the organization’s future is going to look like, should you realize your mission statement, and the tasks at hand.

Hire the right person, or don’t hire at all. Always. No exceptions. Bobby Staten went into detail about hiring and how selecting the wrong person for a position — or someone you’re not entirely sure about — can wind up costing an organization precious time and money in the long run.

Talk to one person you’ve never talked to before, and do this every single day of your life. And not just on the phone. It’s been found that talking to stranger can not only aid your overall well-being, but it can expand your business. Don’t be afraid of phatic expressions, because they usually lead to conversation that’s meaningful and substantial. Remember, every opportunity is attached to a person.

“If you’re looking for an opportunity, including one that has a financial payoff, you’re really looking for a person,” said entrepreneur and author Ben Casnocha.

A hard kitchen floor is the best place to take a 20-minute nap after laying block all day. Frank Gandora, president of Creative Hardscapes in Colorado, explained this. He also went into how you should bid the situation, not the job, and why a contractor is constantly trying to buy new machines.

For more details on the next workshop this spring, email Carrington Blencowe.

A Car Ride From the Big Apple, a Sanctuary in the Catskills

It’s late in the afternoon on a Friday. Almost the weekend. Architect Jason Shannon is on speakerphone, in his car, giving details about the very place he’s driving to from New York City: a concrete block home he and his wife designed that rests in Upstate New York in a county once famous the world over for retreating from Manhattan, and comedy.

“It’s our house, my wife and I, so we got to use our own personal desires for it.”

Jason and his wife, designer Paola Yañez, together run J_spy, in Jersey City, New Jersey — a firm that was recently featured for this project in dezeen.

“When it came down to our main material,” he recalls. “I think masonry we liked a lot because we live in the New York City area and we deal with a lot of old townhouses that are brick.

“They’re a hundred years old but everyone still desires them because they look great.”

With a cut stone look in mind, they went to NCMA member Kingston Block where they were shown a number of options — namely the ground face colors. They went with the darker variation.

“It’s almost like a terrazzo in a way because it’s smooth but you still see the texture of it.”

“[Concrete block] was a good, affordable option to get the look we were going for.”

As an easy retreat from the Big Apple, the location makes a lot of sense. There’s a lot of history backing it up.

Where the home rests, in Upstate New York’s Sullivan County, is the very same county where a string of resorts known as the “Borscht Belt” used to be. For much of the twentieth century their stages served as the springboard for the careers of iconic comedians like Jerry Seinfeld, Joan Rivers, Woody Allen, Andy Kaufman, Rodney Dangerfield and dozens more.

No longer an entertainment epicenter, the region is a quiet, ideal location for a peaceful respite from a city famous for its fast pace, honking horns and cantankerous commotion.

Among a dense forest of pines and a few acres of high grass dotted with blueberry bushes, the home looks out onto the raw nature that cradles it. Its connection to the outdoors and its minimal footprint work in tandem through its deliberate design.

“This house shows our design goals unfiltered. This is the kind of work that we want to do: very minimal. It’s taking everything from building code to tech to the client’s desires and distilling it down to something pure and simple.”

“Masonry makes us think of Europe — it’s one of those materials that lasts really well and it’s something that almost gets better with time. It’s one of those materials that you feel like in another hundred years it’ll still look good there.”

“And we wanted something durable.”

The entire space is single story and is 1,145 square feet. It has two bedrooms and an open-plan living/dining area. Resting atop the masonry walls is a white, metal-clad box that ever-so-slightly cantilevers over the structure. The ceiling features skylights that usher in daylight as well as fresh air.

“The house is environmentally sensitive through the use of an extremely efficient geothermal heat pump connected to a concrete radiant floor used for both heating and cooling. The metal clad volume creates overhangs for passive solar heating while creating 14-foot ceilings on the interior,” said the studio, according to a project description.

Photography is by Amanda Kirkpatrick

Iowa State Takes First Place in National Unit Design Competition in Seattle

SEATTLE, WA – Three college teams presented their unique, fresh CMU designs at the 2019 Unit Design Competition during NCMA’s Midyear Meeting last month. After an audience of judges scored the designs upon each presentation wrapping, the results and prizes were announced and awarded.

The team of Noah Torstenson, Christopher Shoemaker, Gregorio Melchiorri and Jasen Langley — all students at Iowa State University under the tutelage of Professor Bo Suk Hur — took first place.

The team’s design, dubbed “Pura block”, wowed the crowd with its bow-tie appearance and versatility — including have the potential to be used as a screen block, or as part of a curtain wall. If stacked with a running bond the form could also give an elegant wavelength pattern.

However, the team really turned heads when they revealed that Pura block contains holes (rebar penetrations) that can fit both physical and chemical water filtration systems to help clean highly-polluted rivers.

“There’s a cap to contain interior elements and provide a good looking exterior while also straining out larger elements,” said Jasen Langley. ” The activated charcoal particulate filters out negative chemicals, while the filter itself along with the permeate collector help absorb chemicals. The installed filter is subtle, sealed in place with rod and sealant.”

Second place in the competition was claimed by a team from Starkville, Mississippi under the guidance of Professor Jacob A. Gines at Mississippi State University, and helped along through vital manufacturing and consulting assistance from Fred Dunand, president of NCMA member company Saturn Materials out of Columbus, Mississippi — also one of the competition’s sponsors.

Kayla C. Perez, Grace M. Sheridan and Joseph D. Thompson presented their design, named “The Slant”, which actually was developed during Gines’ spring course and eventually produced as a real, full-scale block at Saturn’s plant.

“We were confident in our design and provided evidence of the feasibility of it by considering all aspects of the competition, such as shipping, mass production and economic efficiency,” said Sheridan.

The design boasted the fact that 216 of them could fit on one pallet.

It also featured acoustic abilities, blocking out sound up to around 1000 Hz.

The team of Nabila Bustilos-Francis, Abigail Gillin and Ashley Teer — from North Carolina State University in Raleigh, North Carolina — rounded out the competition with their design, “Concealed Mortar Unit.”

The design is customized so that when stacked, the mortar isn’t visible from the front, in addition to providing a stronger bond than just mortar on mortar. Inspired by roof shingles and the stylistic philosophy of an architecture firm in Winnipeg, Canada — 5468796 Architecture Inc. — who profess the practice of hiding all joints and fasteners, the custom block is meant to be sustainable too. In the presentation the group talked about precast, recycled aggregate and carbon curing.

“This year’s batch [of finalists] was exceptional,” said Dunand. “And it wasn’t an easy task to determine who would be selected.”

He also said he hopes the competition is inspiring innovation for the next generation.

Manufactured Stone Veneer Program Grants First Ever Certifications

HERNDON, VA – The National Concrete Masonry Association is proud to announce that through their MSV Product Certification Program the first ever certifications for manufactured stone veneer (MSV) products have been awarded. The standout products and recipients are manufactured by ProVia, LLC. and Coastal Stone Company.

The MSV Product Certification Program, developed over the course of several years by dedicated committee members, recognizes products that meet or exceed established product standard requirements made by manufacturers who have established quality systems and educated personnel.

A key requirement for certification is submission of results from a qualified testing laboratory demonstrating that the products meet the requirements of ASTM C1670/C1670M, Standard Specification for Adhered Manufactured Stone Masonry Veneer Units. This standard includes requirements for physical properties of MSV units, including compressive strength, freeze-thaw durability, drying shrinkage, shear bond strength and dimensional tolerances. In addition to test results, applicants must also provide a quality system manual for production and evidence that personnel have completed education courses relative to MSV.

The MSV Product Certification Program recognizes producers and their products that have a commitment to quality and ensures that products comply with the ASTM standard. The “NCMA MSV Certified Manufactured Stone Veneer Product” mark is a visual reminder of that commitment to quality, and can be displayed on packaging and promotional materials for certified products.

“Quality units lead to quality projects” says Bob Thomas, NCMA President. “The MSV Product Certification Program communicates this commitment to specifiers and the design community. ProVia LLC and Coastal Stone Company are commended for becoming the first NCMA members to have completed the certification process.”

The certification program is available to members and non-members of NCMA who are engaged in the production of manufactured stone veneer units. To find out more about this program, click here.

Richard Bennett Honored With NCMA’s Industry Champion Award

SEATTLE, WA – Richard M. Bennett, P.E., PhD, professor and director at the University of Tennessee in Knoxville, was presented with NCMA’s Industry Champion Award August 8, 2019, at the association’s annual Midyear Meeting in Seattle, Washington.

The NCMA Industry Champion Award recognizes individuals that make significant contributions in roles beyond what can be accomplished by the association alone, and honors these meritorious contributions that support the advancement of the use of concrete products.

An award recipient already many times over – including the The Masonry Society’s (TMS) President’s Award in 2016 — Bennett was nominated by ten different individuals who had affiliations with not just NCMA, but other associations, organizations, companies and groups within the industry that collectively demonstrated the highest admiration for both the career and work he’s put forward. In doing so, as peers they have also recognized his legacy for the vision, leadership and passion that have contributed to advancing concrete masonry design and construction.

Bennett’s lauded engineering career started in Ohio in the late 1970s. After receiving his undergraduate degree from Cleveland State University with a civil engineering focus in 1979, he continued to study within the discipline and obtaining both a masters and doctorate from the University of Illinois in Urbana in 1981 and 1983.

Since then, he has been a professor at UT, and while maintaining that growingly prestigious day job, he’s managed to tally many a milestone within the masonry industry.

Bennett has chaired multiple TMS subcommittees throughout the years and served as chair during some of the most important cycles. He is recognized by many as the most prolific developer and reviewer of code change proposals, integrating some of the latest and greatest practices into TMS 402/602. He is also an active member of ASTM Committees C12 and C15; bringing these practical and material-based procedures back to his classroom.

He was instrumental in organizing and participating in a recent veneer summit that managed to bear the fruit of new engineered design methods for both anchored and adhered veneers installed over thick layers of insulation. He was also part of the group of five people that met and developed the latest version of the Direct Design Software, helping to refine functionalities through his insightful input.

“There are those that are highly competent technically and professionally, those that radiate effective leadership and responsibility, and those that have the ability to skillfully communicate delicate and complex topics with seamless ease,” said Jason Thompson, NCMA’s Vice President of Engineering. “Richard encompasses all of these facets in both tangible and intangible ways to help advance the masonry industry. His contributions to the researching, analyzing, and teaching the art of masonry design are immeasurable.”

“He’s been involved with a bunch of things that we as an industry not only need to advance, but he’s also recognized for us some of the drivers out there in the marketplace,” Thompson continued. “He brings all of this back to his classroom and transforms it into practical communication and education for his students while also working with us as an industry and framing his expertise in a very similar practical manner.”

“In and around our industry you simply can’t find someone more dedicated, more knowledgeable than Richard Bennett,” said Robert Thomas, NCMA president. “To be a truly effective educator you have to have a deep, keen understanding of the material you’ve attempting to imbue. And it’s more than just teaching — it’s igniting curiosity and elucidating the big picture. In addition to his many students, we are just thankful that Richard has taken all this time to help inspire us, too. We’re so proud to extend this honor to him.”

Bennett has been supported throughout his career by his wife Linda and his daughters.

David Biggs Honored With NCMA’s Industry Champion Award

SEATTLE, WA – David Biggs, the principal of Biggs Consulting Engineering based out of Saratoga Springs, NY, was presented with NCMA’s Champions Award August 8, 2019, at the association’s annual Midyear Meeting in Seattle, Washington.

The NCMA Industry Champion Award recognizes individuals that make significant contributions in roles beyond what can be accomplished by the association alone, and honors these meritorious contributions that support the advancement of the use of concrete products.

The first individual not employed by a member company to be appointed to the NCMA Education and Research Foundation Board of Trustees, Biggs was recognized for his vision, leadership and passion for advancing concrete masonry design and construction.

Raised in Troy, NY, a tight-knit community surrounding the many manufacturing plants that dominated the region at the time, Biggs began studying engineering and playing soccer at Rensselaer Polytechnic Institute (RPI), in the very same town. Upon graduation, in 1972, he participated in masonry and welding apprentice programs, to better understand the materials he would spend his career designing with, and improving. In 1977, he joined forces with a fellow RPI graduate Tom Ryan to form their own firm, a partnership that would last until 2010, when Biggs sold his interests to pursue his innovative ideas and traveling the world and lecturing.

Since then, he has worked helping developing building codes and preserving historic structures in places like Egypt, the Czech Republic, Iraq, Turkey, Italy and New Zealand.

Following September 11, 2001, Biggs was a member of the Building Assessment Team assigned to investigate the World Trade Center disaster for the Federal Emergency Management Agency (FEMA) and the American Society of Civil Engineers (ASCE) where he helped assess and investigate the performance of the structures in and around Ground Zero.

A “mason’s engineer” he’s been instrumental in a number of turning points for the industry. He was instrumental in developing an industry coalition including NCMA, MCAA, the International Masonry Institute, and others. Most recently, he created another coalition of the industry to launch the Building Information Modeling for Masonry Initiative. This group has developed many new tools for integrating masonry into BIM platforms, and Biggs served as the program coordinator (as well as primary advocate) from the beginning.

Biggs has a great ability to evaluate complex failures and suggest practical solutions that often save masons from being solely and unfairly blamed.

“While David Biggs is a design practitioner that works with all building materials, he has consistently had a passion for masonry,” said Rick Roach of Barnes & Cone, Inc. in Syracuse, NY. “Fortunately for our industry, he has channeled that passion for helping the masonry industry to grow and advance. He has challenged the different segments to work together on issues that cross boundaries and has served so many important roles.”

An adjunct professor and educator over the course of his accomplished career, Biggs helped develop the Hybrid Masonry Structural Building Concept, a precursor to a project funded by the National Science Foundation to research seismic response of such structures.

“There is only one David Biggs in this world,” said Robert Thomas, NCMA president. “We should be thankful that he is working to support us. To say that he is a worthy recipient of this honor is an understatement. We’re extremely proud as association to extend such laurels.”

Biggs has been supported throughout his career by his wife Monica, his sons Daniel and Mark, and the rest of his family.